Definition of Single-phase VFD, Three-phase VFD

- Definition of Single-phase and Three-phase VFDs

- Why do we need to use VFDs?

- Key considerations before purchasing a VFD

For those of you who are technically inclined, content below might be quite basic. However, it can be very useful for those who lack experience. Therefore, would you mind joining DAT in reviewing some main points?

1. What are single-phase and three-phase VFDs?

2. How do VFDs work?

3. Benefits of VFDs.

4. Important factors to consider when using VFDs

5. Which brand and where should I purchase a VFD?

1. What are single-phase and three-phase VFDs?

A VFD is a device that alters frequency of current supplied to coil inside a motor, thereby allowing motor’s speed to be controlled infinitely without need for mechanical gearboxes. VFDs come in various types. If we classify them based on input power source, we have two fundamental types: single-phase VFDs and three-phase VFDs, depending on whether input power source is single-phase or three-phase. Among these, three-phase VFDs are widely used and more popular. Additionally, if we categorize them based on voltage, we have 220V and 380V VFDs.

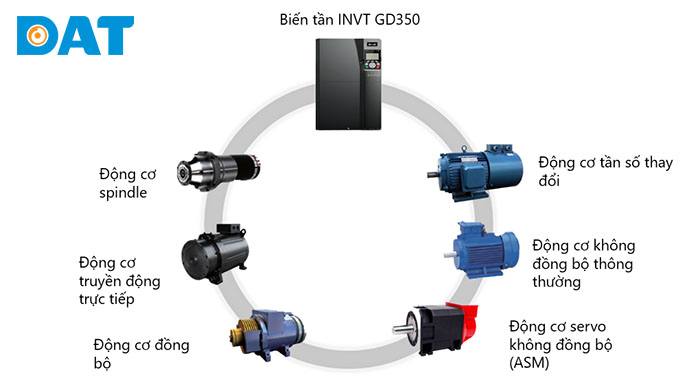

Modern VFDs can control most types of three-phase electric motors, such as asynchronous three-phase motors, synchronous motors, frequency-changing motors, asynchronous servo motors (ASM), direct drive motors, spindle motors, with various power ranges. The choice of appropriate VFD type depends on usage requirements and type of motor.

2. Principles of Operation of VFDs

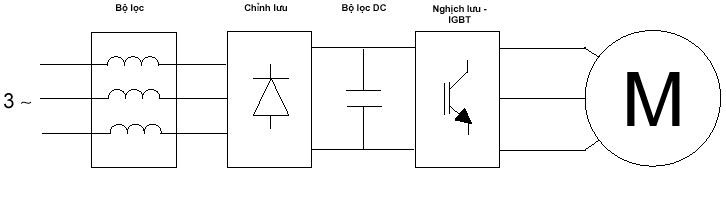

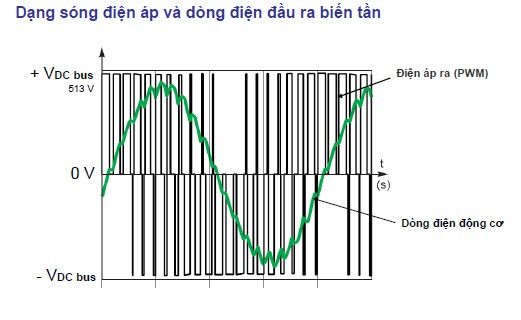

Operating principle of a VFD is relatively straightforward. Firstly, single-phase or three-phase alternating current is rectified and filtered into direct current. This is achieved through a rectifier bridge and capacitors. As a result, power factor (cosphi) of VFD system is not dependent on load and maintains a value of at least 0.96. This direct current is then inverted to symmetric three-phase alternating current. This process is commonly accomplished using Insulated Gate Bipolar Transistors (IGBTs) and Pulse Width Modulation (PWM) techniques. Advancements in microprocessor and semiconductor technology have allowed for high-frequency switching, minimizing motor noise and iron core losses.

Output three-phase alternating current voltage can be adjusted in terms of amplitude and frequency according to control unit’s settings, thereby enabling control of motor speed as required.

Modern three-phase VFDs incorporate various control modes, including V/F control, Space Vector Pulse Width Modulation (SVPWM), Proportional-Integral-Derivative (PID) control, Sensorless Vector control, Torque control, Static Var Compensator (SVC), Closed-Loop Vector control, and more, catering to a wide range of load types. Additionally, advanced models often feature extended functionalities such as Programmable Logic Controller (PLC) integration, PG cards, and support for various communication protocols like Modbus RS485/RS232, Ethernet, Fieldbus, Profibus, Profinet, CanOpen, Bluetooth, enabling remote monitoring and control.

3. Benefits of Using VFDs

The most notable advantage of a VFD in a motor drive system is ability to infinitely adjust motor speed. This flexibility is achieved by altering frequency, and subsequently, speed of motor, within a wide range, simply by adjusting drive settings.

Motor Protection and Mechanical Wear Reduction

When starting a motor directly from power grid, issues like shock and mechanical wear are uncontrollable. A VFD enables smooth motor starts, even in continuous start-stop operations, significantly reducing mechanical wear.

Energy Efficiency and Electrical System Protection

Direct motor start-up from grid leads to a high starting current, resulting in increased energy consumption. A VFD ensures a soft start, reducing starting current to a level lower than rated current, thereby saving energy during this phase. Furthermore, this prevents voltage sagging (and potential damage) to other electrical equipment within system. For applications like pumps, fans, and compressors, a VFD can stop motor in an unloaded state, further reducing energy consumption.

Meeting Technological Demands

In industries where synchronous speed control or flow/pressure control is essential, such as paper, textile, plastic, printing, steel, water, and compressed air industries, VFDs are indispensable. They meet technological requirements and enhance productivity.

Increased Production Efficiency

In applications like textiles, dyeing, and plastics, using VFDs can lead to increased production efficiency compared to direct power sources, eliminating bulky and inefficient accessories like pulleys and auxiliary motors.

Nowadays, a VFD is no longer a distant, expensive luxury reserved only for financially well-off businesses. Benefits that a VFD brings far outweigh costs involved. Most modern VFDs provide open hardware/control structures and flexible integration with various fieldbus modules, offering numerous options for designers and users to integrate VFDs with different types of machinery and equipment.

4. Important Factors to Consider When Using VFDs

The first step when using a VFD is to carefully read VFD specifications provided by manufacturer for each product line. This will help you understand correct three-phase VFD wiring and connection standards. To ensure accuracy, it’s advisable to engage reputable entities with highly skilled engineers to handle installation and connection for you. Additionally, you should research supplementary features of product, such as dust resistance, water resistance, corrosion resistance, emergency stop buttons, expandability, to ensure safe and effective equipment installation, usage, and maintenance.

All VFD manufacturers offer different product lines to suit various applications. Therefore, you should conduct thorough research before making a selection. Some key points to note when using VFDs:

- Choose appropriate VFD type based on your application to ensure cost-effectiveness and reliable performance.

- Inside VFD are sensitive semiconductor electronic components, which are highly sensitive to environmental conditions. Given Vietnam’s hot and humid climate, it’s important to ensure your VFD is designed to withstand tropical conditions and is suitable for Vietnam’s climate.

- You need to ensure installation environment meets temperature, humidity, and positioning requirements.

- VFDs cannot operate outdoors; they must be installed in cabinets with ample space and proper ventilation (cabinets must be equipped with ventilation fans). Cabinet location should be in a dry area within a room with a temperature below 50°C, free from corrosive substances, gases, dust, with an altitude of less than 1000m above sea level.

- Thoroughly read user manual, and if any part is unclear or uncertain, do not attempt to connect or modify any parameters on your own.

- Seek guidance from technical experts provided by manufacturer for installation and setup to achieve optimal operation for your application.

- When a VFD indicates an error, consult error code in documentation and investigate cause of error. Only restart VFD after resolving issue.

- Every VFD comes with a quick reference guide. You should document any changes you make to parameters and any observed errors in this guide. This information is crucial for experts when troubleshooting issues.

5. Which Brand and Where Should I Purchase a VFD?

In today’s market, there are numerous brands of VFDs with different origins, such as Siemens, ABB, Schneider, Emerson – Control Techniques, Danfoss, Rockwell, Yaskawa, Mitsubishi, Panasonic, Hitachi, Delta, LS, INVT… For Vietnam businesses, in addition to factors like quality, stability, and responsiveness, quality of service, pricing, and suitability are key factors in choosing a VFD.

Notably, INVT is one of leading global technology conglomerates in the field of manufacturing VFDs, automation equipment, and electric power. INVT has 12 research and development centers with over 900 patents and 220 software copyrights in VFDs – automation; renewable energy; robotics systems; motor control systems for high-speed electric trains, electric cars; smart charging stations for electric vehicles. INVT’s products are widely trusted and used in more than 60 countries worldwide due to their durable, stable, and versatile quality, with a wide range of VFDs from standard to high-end at very affordable prices. Some product lines that have marked INVT’s name in market include GD20, GD200A, GD35, GD300, CHF100A… with power ranges from 0.2-10,000 kW. Regardless of industry you are in, there will be a suitable INVT VFD model for scale, requirements, and technical characteristics of your operating plant.

For segment of VFDs originating from Europe, Siemens VFDs cannot go unnoticed. SINAMICS V20, G120, G120C, G130, G150 series are standard, versatile low-voltage VFDs that are widely trusted on market. With diverse models capable of controlling tasks from basic to medium complexity, well-organized hardware design and functions, Siemens’ SINAMICS low-voltage VFDs offer high reliability and are an economical choice for various industrial applications.

DAT – Distributor of INVT and Siemens in Vietnam Market

DAT Group is exclusive representative of INVT and exclusive warranty center for INVT in Vietnam. In addition, DAT is an authorized distributor of SIEMENS in Vietnam. DAT specializes in providing products and developing leading solutions in Vietnam market in the fields of automation, solar power & energy storage, elevator control, and UPS.

Customers only need to call toll-free hotline 1800 6567 directly or send a request to email: [email protected], our team of engineers will advise and provide specialized solutions to satisfy your needs in the fastest time.