GD35-09 synchronous integrated cabinet to control the rotary cutter

The GD35-09 synchronous integrated cabinet controls the rotary knife cutter for ideal paper cutting results, with an error of less than 0.5mm, the product is cut sharp, beautiful and uniform with a high speed of up to 350m/ minutes and eliminate 100% of waste due to incorrect cutting. The advanced synchronous integrated control algorithm of the GD35-09 cabinet makes the rotary cutter smooth, protecting the blade system and the transmission mechanism of the rotary cutter.

Old-style operating method, many carton packaging factories use traditional solutions to control rotary cutters including mechanical CAM systems, electrical cabinets using separate controllers or PLCs combined with inverters but low, unstable speed.

CUSTOMERS’ DIFFICULTIES

- Very high investment costs and many other costs incurred for foreign experts or specialized engineers to install.

- Depends on the supplier and special engineer specialist of each company.

- Risk of prolonged machine stoppage, slow repair time due to lack of timely support.

- Difficult to replace engine of different type in case of engine failure and urgent need to run goods.

- Certain errors exist, causing loss of paper materials, reduced productivity, and many machines for cutting products that are not beautiful, so they do not meet the strict requirements of product specifications.

SOLUTION ANALYSIS

The configuration of the GD35-09 synchronously integrated cabinet is professionally designed, high quality and fully functional for rotary knife cutters, including:

- Specially designed electrical cabinets

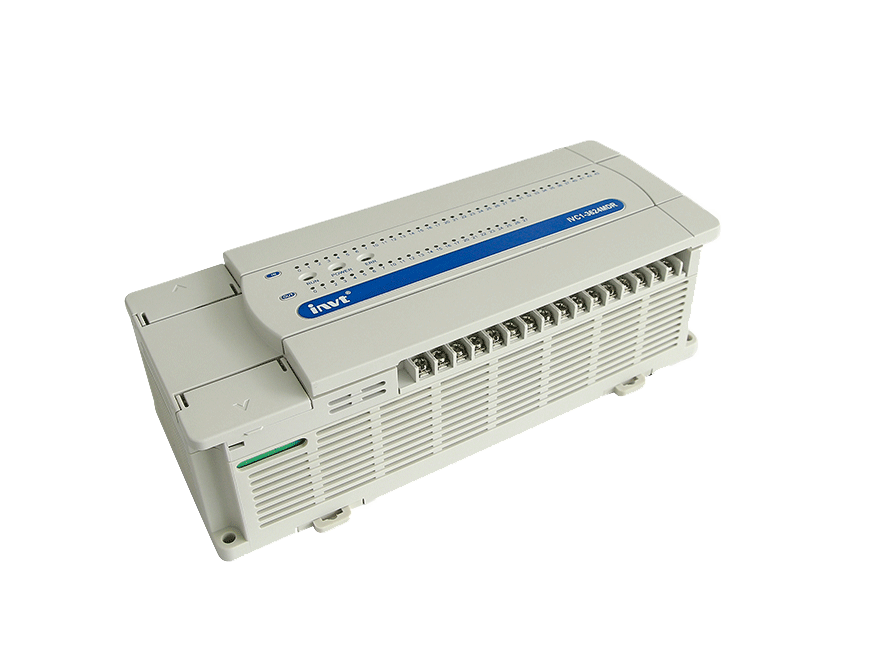

- 1 GD35-09 synchronous integrated inverter with over-capacity

- Premium 10.4” color HMI display for monitoring and operation

- Operation button panel

- 1 inverter to control the conveyor belt

- Oil pump control circuit, Master and Slaver encoder, cut-off sensor, kinetic energy brake and torque booster, electrical cabinet, blower, etc.

SOLUTION ADVANTAGES

- Increase productivity, eliminate 100% waste products and maximize profits

- Easy operation and efficient order management

- Flexible response for both AM and PM engines

- Do not depend on experts and specialized engineers like traditional technology solutions

- Complete solution, available warehouse, 24/7 service

Take a look at DAT's specialized solution design process.

Contact an expert

If you need advice and learn about DAT’s solutions, please contact 1800 6567 to meet with experts today.

Products for solutions

Solution relate:

10.000+

15+

3000+

24h

Let's go with DAT

24/7 SUPPORT

Hotline 1800 6567