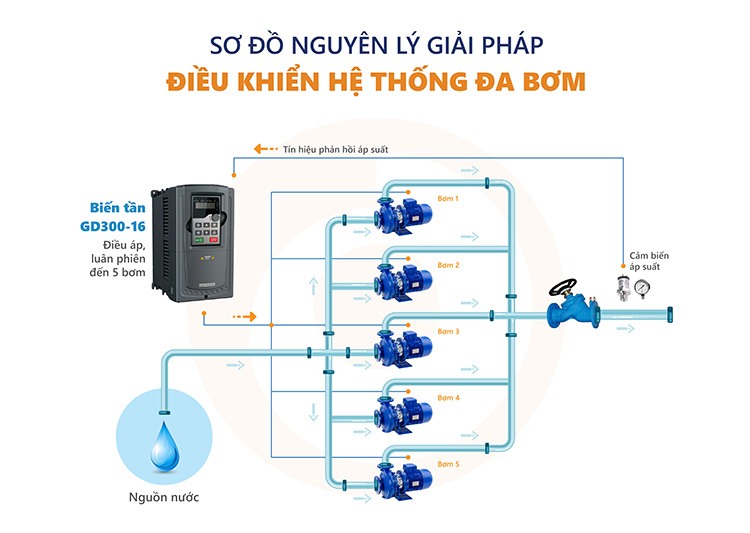

Solutions for pressure control, rotation and power saving for multi-pump systems

The solution uses INVT’s dedicated inverter HVAC GD300-16 to control the multi-pump pressurization system – alternately to ensure stable operation of the pump system, reduce investment costs, save electricity and improve service life. engine.

Water pumps are applied in most areas of life and production, in which multi-pump systems are widely used in industries and activities such as water supply stations, water treatment stations, apartments. high-rise buildings, shrimp farming aeration systems, dyeing machine pumps, fire pumps, sand pumps and a wide range of other applications.

The old-fashioned pump control method used a three-phase motor with star-delta starter or direct grid power and controlled via relay and timer.

CUSTOMERS’ DIFFICULTIES

- Pumps with a lot of running/stopping time shall be reduced their lifetime.

- The pumps always operate at full capacity even though the demand for use is low, causing energy waste.

- Power system voltage drop due to simultaneous starting of multiple pumps.

- Cost and space to build water tower (for water supply station).

- Unstable water pressure and flow affect other systems and break pipes, valves, etc.

- The pumps does not work alternately, some pumps work too much or too little, causing damage and rusting of parts.

- Increased operating, maintenance and service costs.

SOLUTION ANALYSIS

Using INVT’s dedicated inverter HVAC GD300-16 to control the multi-pump pressurization system – alternately helps to completely solve the above problems.

- The inverter GD300-16 receives a signal from the pressure sensor (mounted on the main pipe), the inverter will automatically adjust the frequency, thereby changing the pump speed.

- When the demand for water is high, the inverter will automatically control the pump motor at the highest speed to maintain the pressure. Conversely, when the demand for water is low, the inverter will control the pump motor to slow down or stop completely.

- Inverter GD300-16 controls voltage stabilization, rotation and soft start when adding or reducing pumps (expandable up to 11 pumps), balancing pump operation time, monitoring and controlling over time real.

SOLUTION ADVANTAGES

- Stabilize water pressure and flow on pipes

- The system works continuously even when repairing or replacing the faulty pump

- The motor operates in accordance with the load demand, saving power consumption

- Simple operation system with only 1 inverter, no need for PLC

- Minimizing investment costs when not having to build tanks and water towers

- Prevent rust, mechanical wear and increase pump life thanks to reasonable rotation control

- The inverter helps the motor to start smoothly, avoiding grid voltage drops and pipeline damage

Take a look at DAT's specialized solution design process.

Contact an expert

If you need advice and learn about DAT’s solutions, please contact 1800 6567 to meet with experts today.

Products for solutions

Solution relate:

10.000+

15+

3000+

24h

Let's go with DAT

24/7 SUPPORT

Hotline 1800 6567