Solutions to save energy and improve the durability of hydraulic paper mills

DAT’s solution using INVT’s GD200A inverter allows adjusting the motor’s speed according to the technological cycle to save power consumption, reduce repair costs and improve the durability of hydraulic paper mills.

The hydraulic paper mill uses waste paper as the input material and crushed water into pulp to serve the paper machine to create finished paper.

Crushers are usually available with capacities from 37kW to 315kW because of the large load required to grind waste paper into pulp in large capacity tanks.

The old-style operating method, the mill motor uses star, delta start.

CUSTOMERS’ DIFFICULTIES

- The machine starts directly by mains electricity, large starting current causes factory voltage drop, power consumption.

- Direct start causes the machine to jerk, shake, mechanical shock, damage the motor and equipment such as belts, bearings, grinding wheel, etc.

- It takes a lot of money and time to maintain and maintain machinery.

SOLUTION ANALYSIS

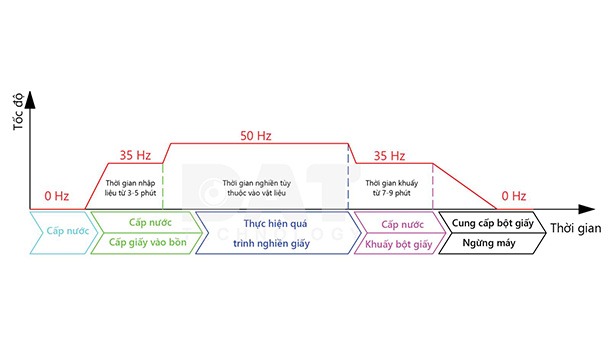

Using INVT’s GD200A versatile inverter to control the motor speed according to the actual requirements of the load in the stages of inputting, crushing, stirring, stopping the machine…

- Input time and discharge time only need to run at low speed, from 30-35 Hz, saving from 8% to 10% of electricity consumption.

- At the last stage, when starting to add water to dilute, the pulp is almost finished grinding, the motor speed can be reduced to ~40 Hz, saving 5% of electricity.

- For softer scraps such as newspaper, printing paper, the mill can operate at 45 Hz, saving ~3% of electricity consumption.

SOLUTION ADVANTAGES

- Protect the power grid, avoid voltage drop when starting

- Improve work efficiency

- Reducing power consumption

- Protect engine, mechanics, reduce maintenance costs

- Meeting technology needs

- Complete solution, available warehouse, 24/7 service

Take a look at DAT's specialized solution design process.

Contact an expert

If you need advice and learn about DAT’s solutions, please contact 1800 6567 to meet with experts today.

Products for solutions

Solution relate:

10.000+

15+

3000+

24h

Let's go with DAT

24/7 SUPPORT

Hotline 1800 6567