Servo Motors and Benefits, Applications of Servo Systems

1. Introduction to Servo Systems

2. Differences between AC Servo and Step Motor

3. Benefits of Using AC Servo

4. Some Applications of AC Servo

5. Comparison between Servo Drive and VFD

6. Some AC Servo Series by INVT

1. Introduction to Servo Systems

A servo system consists of three main components: servo drive, servo motor, and encoder. It is a closed-loop control drive system that receives signals and quickly and accurately executes commands from a PLC. Servo systems are used in various applications, ranging from basic to specialized, in different industries.

Learn more about definition, components, and working principles of servo motors

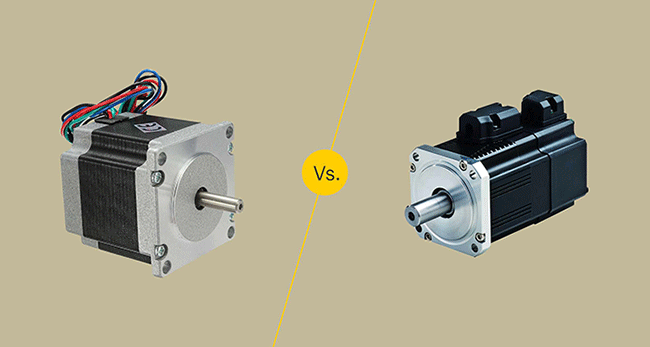

2. Differences between AC Servo and Step Motor

Servo motors and step motors are two commonly used types of motors for controlling angular rotation in applications that require high precision. However, they have several differences:

| AC servo | Step Motor | |

| Drive | Complex, needs to be purchased as a complete set from manufacturer | Simpler than servo, can be self-constructed |

| Speed | Speed High speed (up to 3000-5000 rpm) | Lower speed (up to 1000-2000 rpm) |

| Control mode | Control Modes Speed, position, torque | Basic position control |

| Step slippage phenomenon causing control error | Occurs rarely. Motor continues to run smoothly when load increases | If load increases, step slippage may occur |

| Control method | Closed-loop control | Open-loop control |

| Noise and vibration | Very minimal | Prone to vibration and noise |

| Cost | Relatively high | Inexpensive |

| Durability | Equipment is complex and requires regular maintenance | Simple, compact size, low maintenance, and robust |

| Resolution | Very high, up to 23 bits (dependent on encoder) | Low (usually around 0.36 – 15°) |

3. Benefits of Using AC Servo

Compared to conventional AC asynchronous motors, servo motors offer several advantages:

- Precise control over speed, position, and torque.

- Constant torque in speed range from 0 to rated speed, making them suitable for high-torque, low-speed applications.

- High operational efficiency, minimal heat generation, and low vibration.

- High-speed operation and rapid changes in frequency.

- Fast response and low inertia (almost no inertia).

- Smooth, lightweight, and energy-efficient (can save 5-20% energy compared to regular motors).

- Compact size, less prone to damage.

However, using servo motors requires programming knowledge to fully leverage their flexibility for practical applications.

4. Some Applications of AC Servo

With their outstanding features, high performance, accurate position, speed control capabilities, and stable long-term operation, AC servo systems are suitable for various applications in different industries, including:

- Robot arm control

- CNC machine systems

- Mask manufacturing machines

- Flying cut-off systems

- Nylon bag cutting machines

- Packaging machine systems

- Industrial printing machines

- Material handling and sorting systems

- Control of electronic device manufacturing machines…

Related article: Applications of Servo Motors in Industry

5. Comparison between Servo Drive and VFD

Fundamentally, both servo control and VFDs are used for motor control. While servo drives provide flexible and precise control over speed, position, and torque, VFDs mainly rely on frequency changes to control motor speed.

For optimal selection, here’s a comparison between VFD and servo control:

| VFD | Servo Drive | |

|---|---|---|

| Control Application | Used for applications that don’t require high speed or precision control, stability is sufficient | Used for applications requiring high-speed, precise control of position, speed, and torque, rapid and continuous changes in state |

| Control mode | Basically controls motor speed | Controls position, speed, and torque |

| Ability to control multiple motors | A VFD can control multiple motors | A basic servo drive only controls a single servo motor |

| Responsiveness | Up to 100 rad/s or less Faster | Around 200 to 15000 rad/s |

| Precise position and stop control | Up to about 100 µm | Up to about 1µm |

| Lock mode | No | Yes |

| Start/stop frequency | About 20 revolutions per minute or lower | About 20 to 600 revolutions per minute |

| Maximum Torque | Approximately 150% | Approximately 300% |

| Power Range | Approximately 100W to 300kW | Approximately 10W to 60kW |

| Size | Size Larger and heavier | Compact and lightweight (for same power) |

| Investment Cost | Relatively low | Higher |

In some cases, if servo drive is malfunctioning while servo motor is still functional, special variable frequency drives (such as GD35, GD350) can be used as a replacement for servo drive to save costs.

More detailed article on differences between VFD and servo drive control

6. Some AC Servo Series by INVT

a) DA180 – New Generation AC Servo Series

DA180 is a new generation versatile AC servo product line (0.1 – 1kW) by INVT, used for simple and flexible applications. It is applied in various industries such as mask manufacturing machines, packaging machines, filling machines, and some steel industry applications.

b) DA200 – Premium High-Performance AC Servo System

DA200 AC servo drive is designed for high-performance applications that require fast response and precise control of position, speed, and torque. It is applied in CNC machines, robotic arms, nylon bag cutting machines, bag making machines, and more.

DA200 offers a wide power range:

- 1P 220V: 200W – 1000W

- 3P 380V: 1kW – 55kW

c) MH800 – Hydraulic Plastic Injection Molding Servo System

MH800 is a premium hydraulic servo system specifically designed to control pressure and flow for hydraulic plastic injection molding machines. It provides high precision and quick response, saving up to 80% of energy, improving product quality, and enhancing efficiency of injection molding process.

Power range:

- 3P 380V, 4.4 kW – 75 kW.

Refer to article for more details: Popular INVT AC Servo Series

DAT is only trusted entity authorized by INVT to establish and operate service centers in Vietnam. These centers provide professional and immediate warranty, repair, and upgrade services for inverters with original components and European standard processes by INVT.

With over 17 years of experience in automation and trust of over 10.000 customers, DAT takes pride in being a major supplier of genuine products and specialized solutions, ensuring timely response to all needs and delivering highest efficiency to customers.

For detailed information and consultation, please contact hotline 1800 6567 (toll-free).