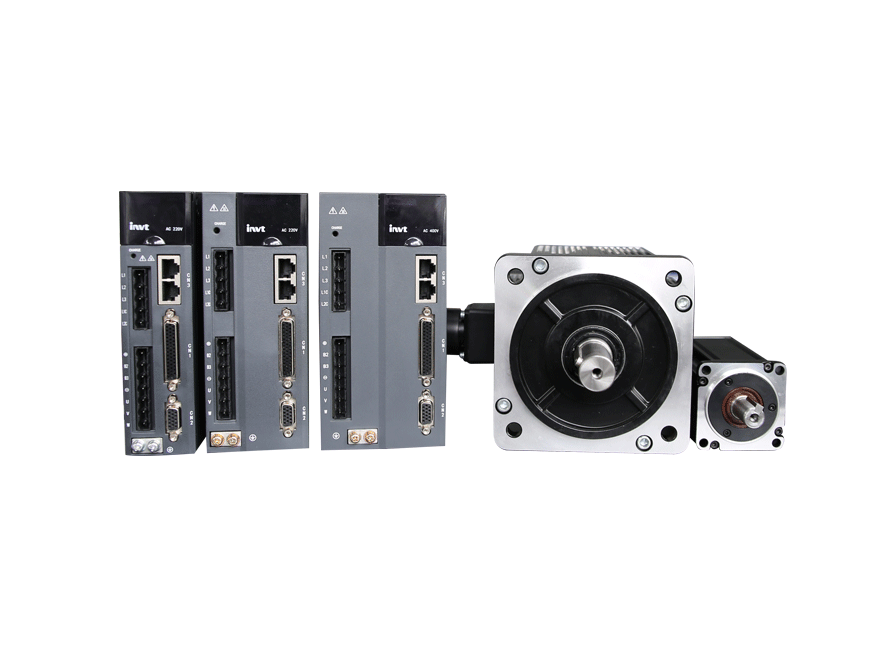

MH800 High Performance Hydraulic Servo Drivers

- Free delivery within Ha Noi, Ho Chi Minh, Can Tho

- Free installation

| Brand: INVT | Warranty: 18 Months |

| Model | Rated current | Peak current 300s | Peak current 30s | Applicable motor power |

| SV-800-4R4-33-S-00 | 13A | 18A | 25A | 4.4kW |

| SV-800-5R5-33-S-00 | 18A | 25A | 35A | 5.5kW |

| SV-800-7R5-33-S-00 | 22A | 31A | 46A | 7.5kW |

| SV-800-011-33-S-00 | 26A | 34A | 53A | 11kW |

| SV-800-015-33-S-00 | 30A | 42A | 64A | 15kW |

| SV-800-018-33-S-00 | 38A | 54A | 95A | 18kW |

| SV-800-025-33-S-00 | 45A | 59A | 113A | 25kW |

| SV-800-030-33-S-00 | 60A | 85A | 141A | 30kW |

| SV-800-037-33-S-00 | 75A | 106A | 191A | 35kW |

| SV-800-045-33-S-00 | 110A | 155A | 255A | 45kW |

| SV-800-055-33-S-00 | 123A | 160A | 283A | 55kW |

| SV-800-075-33-S-00 | 156A | 220A | 318A | 64kW |

10.000+

15+

3000+

24h

1. Expert-level solution for hydraulic pressure device;

2. Adopt EMC design to realize low noise and low electromagnet interference;

3. Outstanding anti-trip performance and strong adaptability to ensure reliability in hostile grid, temp, RH and dusty environment;

4. Monitor the temp change of motor and drive during the whole process, adjust system overload amplitude limiting in real time; ensure the safe and stable operation of the motor and drive to prolong the service life of the system;

5. Simple gain adjustment and gain switching function; support four groups of gain setup. Gain switching can be realized through I/O input, communication or internal variables to satisfy flexible demands in the process.

6. Control the pressure release of min reversal amount through setting the pressure release speed and torque to prolong the service life of the oil pump

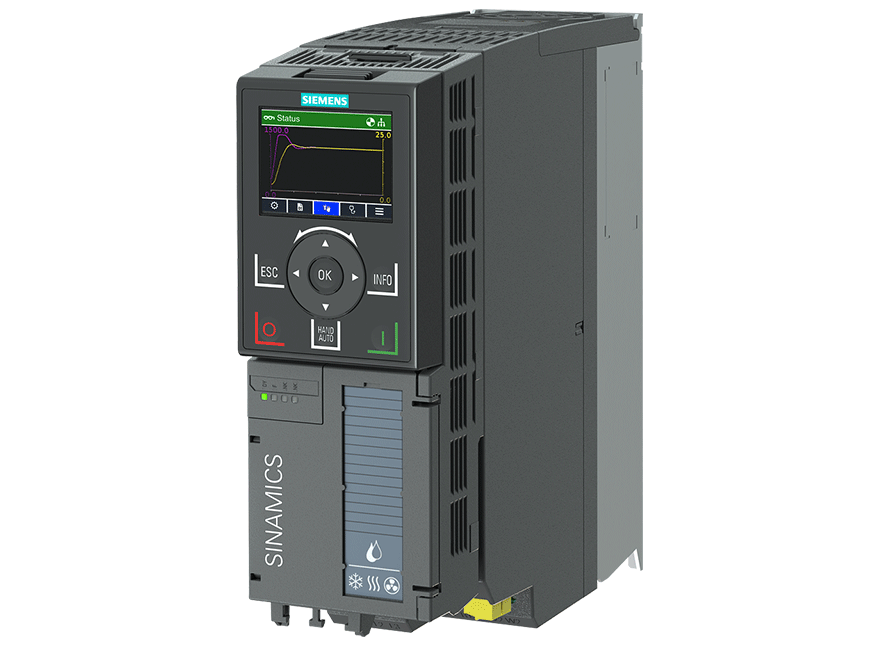

7. Abundant communication interface, support bus communication protocols eg Modbus, CANopen and EtherCAT. Mould protection, energy consumption management and remote monitoring function can be realized through networking.

8. The six digital inputs and four digital outputs can be assigned freely via parameters. Modification can be made through LED panel or external HMI for users’ convenience;

9. Comprehensive product lines and abundant power bands covering 4.4kW~75kW to satisfy the demands of small vertical injection machine, injection machine, die-casting machine, hydraulic machine, aluminum extruder, plate shearing and bending machine.

Compared to MH500, MH800 is equipped with more abundant power bands and communication interfaces, which greatly improves the transmission speed of device operation information and makes it easier to realize networking of multiple devices and integrated networking control of intelligent auto production lines. The drive adopts EMC design with faster pressure and speed response and smaller fluctuation of the steady pressure, thus making oil pressure control more smooth and stable and enhancing anti-interference capacity to satisfy low noise and low electromagnet interference requirements.