The popular AC Servo series from INVT currently

INVT is one of the leading international conglomerates in high-tech development of solutions and product manufacturing in the field of frequency converters – automation. INVT continually innovates many new products and solutions with the latest technology and is widely used in over 60 countries. Among them, thanks to its diverse applications from basic to advanced, INVT’s AC Servo lines are increasingly trusted and chosen as the optimal solution to help enterprises enhance production and business efficiency, and increase competitive advantages.

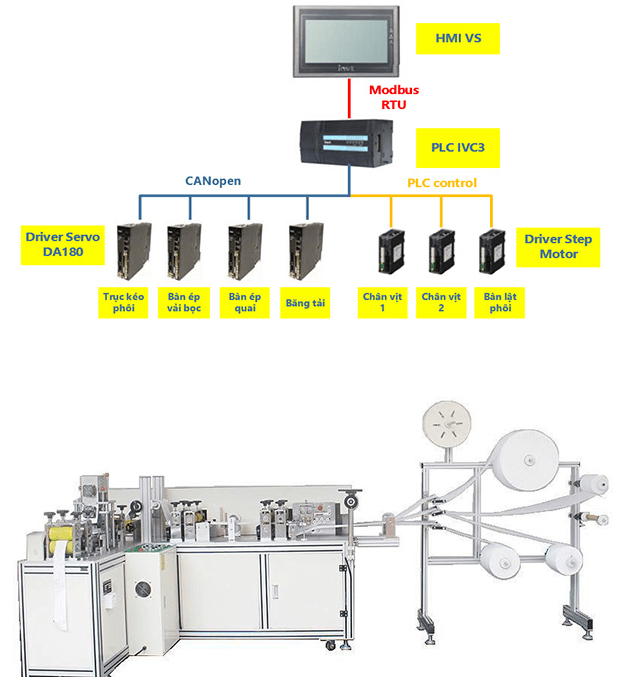

- DA180 – Next-generation AC Servo Line

DA180 is INVT’s new generation, versatile servo product line (0.1 – 1kW) used for simple and flexible applications.

Technical characteristics:

- High-speed response (up to 2.0kHz)

- Internal position control mode with 128 internal position steps coordinated with input signal (extended I/O or bus).

- Lightweight and convenient (45% lighter than DA200)

- High accuracy with absolute 17-bit encoder

- Diverse communication standards: Modbus, CANopen…

- Adaptable to environments: natural cooling with power from 400W downward

- Low vibration frequency control: eliminates mechanical resonance between low frequency and mechanical oscillations, increasing efficiency during operation

AC Servo DA180 is widely applied in industries such as mask manufacturing machines, packaging machines, and filling machines…

2. DA200 – High-end Versatile AC Servo Line

DA200 is INVT’s high-end versatile AC Servo line designed for systems requiring high performance, quick response, and extremely precise position, speed, and tension control.

Technical characteristics:

- Power range: 0.1kW – 55kW

- Fully closed-loop position, speed, torque control.

- Pulse control (position mode), Analog, and Multispeed (speed and torque mode).

- Control accuracy ± 0.03% (speed control mode), ±1 pulse (position control mode).

- E-CAM function with up to 1000 CAM points.

- Communication: Modbus, USB, EtherCAT, CANopen, ProfiNET…

- Encoder resolution: relative 2500 pulses; absolute 17 bits; absolute 23 bits; rotary transformer 12 bits; rotary transformer 16 bits.

- Integrated brake control and internal discharge resistor, external discharge resistor can be added.

- Easy control with remote keypad.

- Parameter setting manually or via computer connection.

- Automatic error parameter saving for analysis and warning. Can save up to 10 errors.

With these outstanding features, AC Servo DA200 is designed for systems requiring high performance, quick response, and extremely precise position, speed, and tension control. It is applied in CNC machines, robotic arms, nylon bag cutting machines, bag sealing machines…

Some prominent applications of Servo DA200:

See more details at: Applications of AC Servo DA200 System in Industry

- MH800 – Specialized AC Servo for Hydraulic Injection Molding Machines

MH800 is a premium hydraulic servo system, designed to control pressure and flow for hydraulic injection molding machine systems with high accuracy and fast response, saving up to 80% of electrical energy, improving product quality, and increasing efficiency for plastic injection molding machine systems.

Technical characteristics:

- Power range: 4.4kW – 75kW.

- Intelligent pressure and flow control algorithm, saving from 20% – 80% of electrical energy consumption.

- Torque control at each operating cycle of the system.

- Low inertia servo motors , high efficiency, fast response.

- Control hydraulic pressure return by reducing pressure and torque to extend pump life.

- Communication: CAN, RS485.

- Pressure control accuracy: ±1bar.

- Flow control accuracy: ±0.5% FS.

- Can withstand overload up to 3 times the rated load, maximum speed can reach 2500 rpm.

DAT is the only trusted unit authorized by INVT to establish and operate a service center in Vietnam. This center provides professional and immediate warranty, repair, and frequency converter upgrades with genuine components and European standard processes from INVT.

With over 14 years of experience in automation and having earned the trust of over 7000 customers, DAT is proud to be a large-scale supplier of genuine products and specialized solutions, ensuring timely fulfillment of all needs and delivering the highest efficiency for customers.

For more detailed information and consultation needs, please contact the hotline 1800 6567 (free call).

Related Posts: