VFD Multi-Pump Control Solution

Multi-pump systems are widely used in both industrial and residential settings. Typically, these systems use traditional pump control methods such as star-delta starters or direct online starters. Consequently, users often face several challenges including voltage drops, high maintenance costs, energy wastage, and reduced system lifespan.

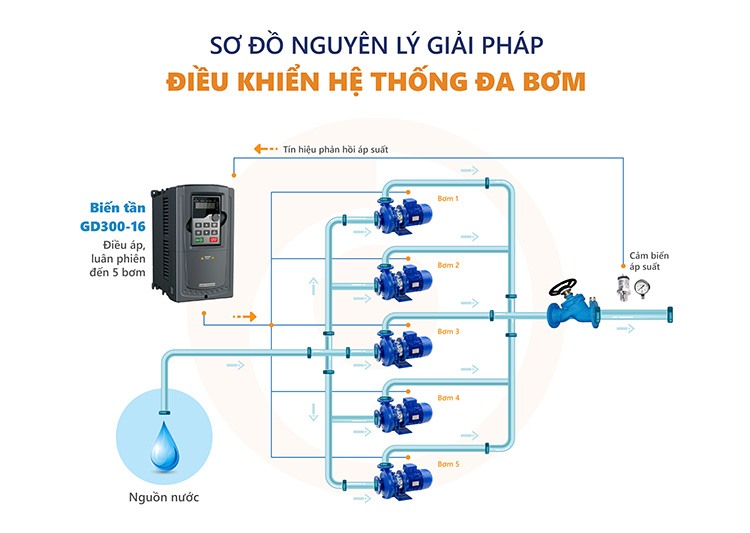

These drawbacks can be comprehensively resolved by using a single inverter to control multiple pumps (inverters controlling two or more motors). So, what exactly is the solution of a single inverter controlling multiple pumps?

1. Concept of an Inverter

An inverter is a device that converts direct current (DC) or alternating current (AC) into AC with adjustable frequency and voltage.

Read more in the detailed article The Operating Principles of Inverters

2. Difficulties Without Using Inverters for Pump Control

Currently, many customers in the water supply industry encounter numerous difficulties and disadvantages when starting pump motors directly, such as:

- System voltage drop due to starting multiple pumps simultaneously.

- High costs of constructing water towers.

- Unstable system pressure and water flow.

- Reduced lifespan of the pump system due to direct starting.

3. Benefits of Using Pump Inverters

- Inverters ensure stable output pressure and continuous water supply.

- They save up to 10% of the consumed electrical energy.

- They offer the best protection for pumps, preventing voltage drops in power lines.

- They protect the motor from short circuits, phase loss, phase imbalance, overloads, and overcurrents.

- Motors start smoothly, avoiding pressure shocks in the pipeline.

- They reduce mechanical wear and tear on pipes.

- They automatically manage alternating and backup pump modes.

4. Can One Inverter Control Multiple Pumps?

For standard water treatment and supply systems that use multiple pump motors, stability in pipeline pressure and flow is essential. To meet this requirement, the pump motors need to alternate operation, and a backup pump must be available if any operating pump fails. One solution is to use a PLC to control each pump’s inverter. However, this approach has the drawback of high investment costs, including the PLC controller and numerous inverters.

Understanding these issues, DAT and the international technology group INVT have collaborated to research, develop, and introduce the GD300-16 inverter solution for alternating water pump control and stable pressure. The GD300-16 is a specialized inverter for solutions involving one inverter controlling multiple pumps, also known as multi-pump systems (one inverter controlling two or more pumps). This inverter can control up to 11 pumps.

Advantages of Multi-Pump Inverter Control:

- It meets the requirements for alternating and backup pump control, ensuring stable pressure and flow in pipelines.

- The integrated controller within the inverter eliminates the need for a PLC, resulting in a compact and stable control cabinet design.

- It incorporates many functions for pump protection and pressure shock prevention to safeguard pipelines.

- Lower investment costs are achieved by reducing the number of inverters needed for each pump, as one inverter can control multiple motors without a PLC controller.

5. About DAT

DAT Technical Co., Ltd. is a leading provider of products and solutions in Vietnam in the fields of automation, elevator control, solar power – energy storage & UPS.

With over 15 years of development, DAT has gained the trust and cooperation of more than 10,000 customers nationwide, making it the top provider in terms of the number of inverters sold in the Vietnamese market.

6. Product Introduction

GD300-16 series is a specialized inverter for HVAC systems, developed according to the application and control requirements of the HVAC industry, and it can be widely used in heating systems and water supply systems.

Applications:

- HVAC systems.

- Water pressure control for high-rise buildings.

- City water supply stations.

- Water treatment plants.

- Multi-pump systems for shrimp farming.

- Soft starting for flour mills.

For more details on selecting the right inverter for your needs, refer to the article How to Choose the Right Inverter

7. Contact for Purchase

Customers can simply call the Hotline: 1800 6567 (toll-free) or chat directly with a consultant via the chat box on the bottom right corner of your screen.

DAT is always ready to provide the quickest support!

Related Articles: