Servo solutions improve productivity for automatic packaging machines

The packaging machine control solution uses Servo, PLC, HMI and inverter to increase operating efficiency by 30%, the system is stable, the accuracy is up to 0.5mm and it is easy to change the quantity or size of product packaging.

Packaging machines perform the job of wrapping and containing goods to protect goods during transportation, storage and for the convenience of consumers during product consumption.

The old-style packaging machines used a specialized automatic control system using cam and clutch mechanisms, which could basically meet production requirements but did not bring the best efficiency.

CUSTOMERS’ DIFFICULTIES

- Slow speed machine causing low yield

- Lack of flexibility, it is very difficult to adjust the length and quantity of products according to needs

- Complex system that is make it difficult for operators to operate

- The machine vibrates, shakes, makes noise and requires regular maintenance and repair

SOLUTION ANALYSIS

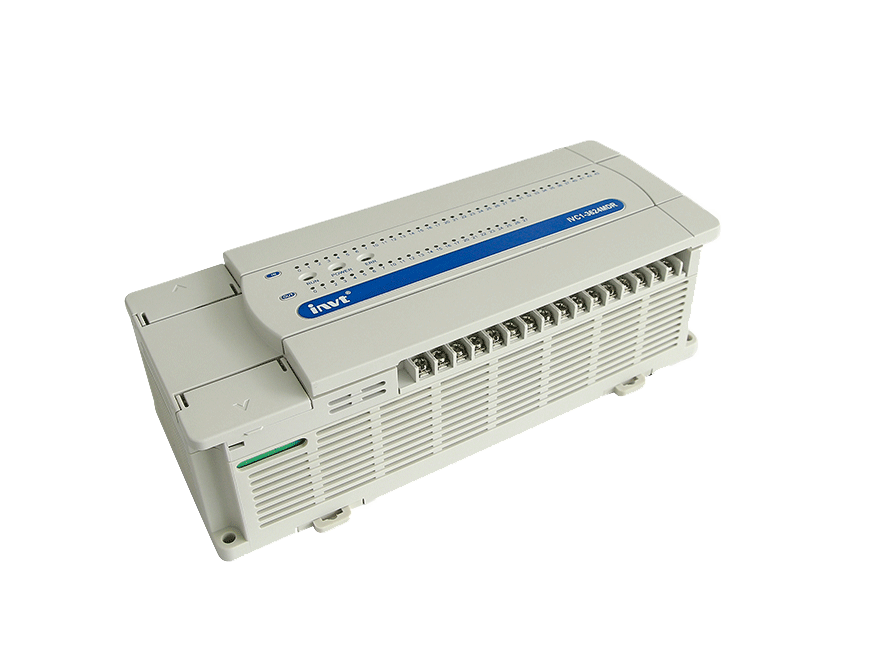

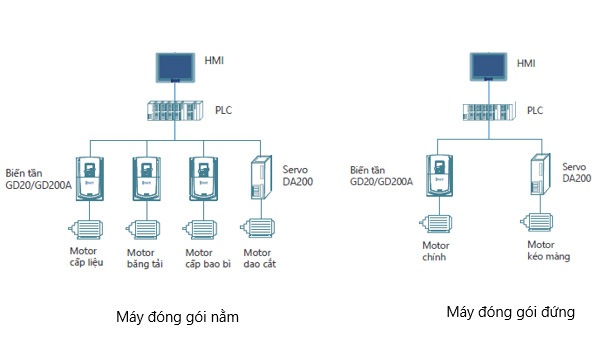

- PLC IVC series: control the whole machine operation

- HMI series: allows the user to easily operate and monitor the operation of the machine.

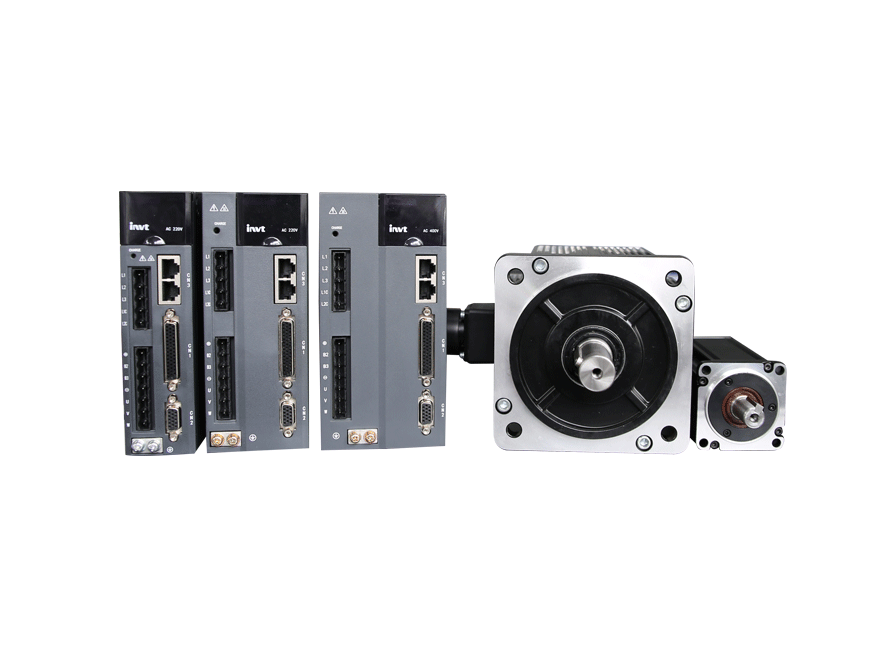

- Servo DA200 drives the film pulling motor (with vertical packer) or drives the rotary cutter motor (with the horizontal packer)

- GD20/GD200A: speed control of the main motor (vertical packer) or the conveyor, feeding, and packing motors (horizontal packer)

- Use Modbus communication to communicate devices with each other during operation.

SOLUTION ADVANTAGES

- The device is compactly integrated in the electrical cabinet. Connecting becomes faster, easier

- The machine speed is fast, the parts operate smoothly and synchronously, the machine does not vibrate

- Satisfying technology requirements, the cutting system is accurate with the cutting length error less than 0.5mm, the weight error about 2% depending on the product.

- The machine operates stably, automatically adjusts the speed when the mechanical part is worn, reducing maintenance costs.

- Easily save parameters and change product size and weight according to needs via the HMI screen.

Take a look at DAT's specialized solution design process.

Contact an expert

If you need advice and learn about DAT’s solutions, please contact 1800 6567 to meet with experts today.

Products for solutions

Solution relate:

10.000+

15+

3000+

24h

Let's go with DAT

24/7 SUPPORT

Hotline 1800 6567