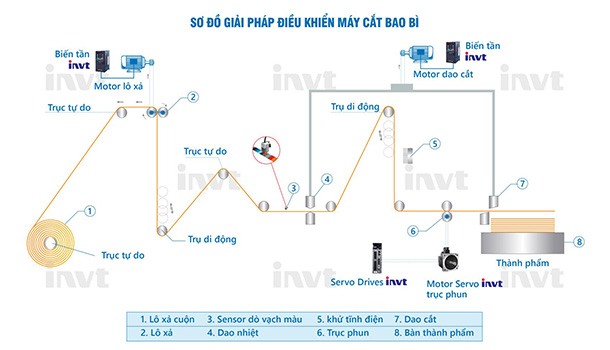

Precise control solution, increasing efficiency for plastic bag cutting machine

The solution uses PLC, HMI, Servo programmable controllers and INVT inverters to ensure stable operation of the packaging machine, accurate cutting for even products at a speed of up to 130 pieces/minute. The solution helps users easily change the product speed and length to suit production needs.

The plastic bag cutting machine performs the final stage in the process chain to create finished plastic bag packaging, which is commonly used in today’s life.

The old-style operating method uses a VS motor to regulate the machine speed and other components (unloading, sealing, cutting, and spraying) are linked together through a mechanical transmission.

CUSTOMERS’ DIFFICULTIES

- Low productivity and large product length error

- Noisy operation, mechanical loss and energy consumption

- It is difficult to change the machine speed and product length

- Operating complex systems, requiring a lot of mechanical adjustment

- Regularly check and maintain mechanics and engines

SOLUTION ANALYSIS

- PLC PROGRAMMING handle all machine operations

- HMI touch screen: allows users to easily monitor, operate, set speed, product length and other functions, etc.

- Servo SV-DA200 for injection part: control injection shaft according to set length

- GD200A/GD20: control the speed of the motors according to the machine speed

SOLUTION ADVANTAGES

- Easy to change machine speed as well as product length

- The machine speed can be adjusted from 0 to 130 products/minute. The product length can be adjusted from 0 – 3000 mm, supporting line cutting.

- System performance improved significantly, up to 30% better than the old system with a speed of up to 130 products/minute

- The system operates smoothly and accurately to produce beautiful, high-quality products

- Simple operation system, user-friendly interface

- Protects the engine against mechanical shock thus reducing maintenance costs

Take a look at DAT's specialized solution design process.

Contact an expert

If you need advice and learn about DAT’s solutions, please contact 1800 6567 to meet with experts today.

Products for solutions

Solution relate:

10.000+

15+

3000+

24h

Let's go with DAT

24/7 SUPPORT

Hotline 1800 6567