The applications of the AC Servo DA200 system in the industry

AC Servo DA200 System by INVT is designed and equipped with many special features suitable for various modern industrial applications, helping increase productivity and bring substantial profits to manufacturing enterprises.

The development of modern industrial production demands increasingly specialized, sophisticated, precise, and responsive control systems to ensure efficient production processes. This trend has led to a growing demand for servo systems in drive control. With many outstanding features, high performance, precise control of position, speed, torque, powerful operation, and stable operation over long periods, INVT’s AC servo system DA200 is suitable for various applications ranging from basic, versatile to specialized, modern in many different industries.

Servo DA200 system

- Robot Control Application

The AC Servo System DA200 with precise position control, speed control, torque brings high work efficiency, powerful operation, and stable operation suitable for most robot controllers.

|

|

|

Benefits of DA200 for robot systems:

- Simple and user-friendly commissioning.

- Compatible with all robot joint controllers.

- Automatic gain adjustment to quickly achieve optimal performance of each joint.

- The DA200 servo system helps the robot system operate flexibly and accurately. The repeatability accuracy is up to ±0.01mm.

View detailed solution here: Successful application of Servo DA200 for robot stacking bags onto Pallets

- CNC Machine System

With fast response speed, large overload capacity, and high position accuracy, AC servo DA200 enhances the performance of CNC systems in the industry.

Benefits of DA200 for CNC systems:

- Response speed up to 2kHz with a 23-bit encoder.

- Overload capacity up to 300%, robustness ensures stable operation even at high or low speeds, heavy loads.

- Full closed-loop control function helps increase accuracy and reliability.

- Mask Making Machine Application

The solution to control medical mask manufacturing machines using PLC IVC3, HMI VS, and INVT’s DA200/DA180 servo drive helps increase the productivity and efficiency of mask manufacturing machines, effectively addressing customer manufacturing challenges.

Benefits of the solution:

- High machine speed.

- Ensuring synchronous speed between mechanisms and production stages.

- Easy control and operation, Vietnamese language display screen.

- CANopen communication ensures fast data transmission, completely eliminating system interference from high-frequency waves, increasing productivity and product quality.

View detailed solution here: Solution for controlling medical mask manufacturing machines

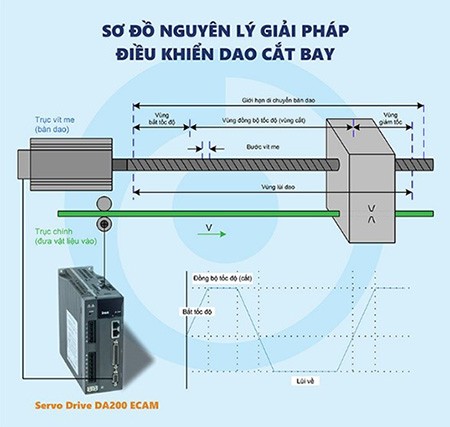

- Flying Shear Cutting System

Flying shear cutting (also known as flying cut-off) is a common application in the industry for continuous cutting of products to a preset length according to conveyor speed. The solution using AC servo DA200 – Ecam – Flying Shear control system for flying shear cutting and rotating cutting helps customers master technology, overcome difficulties, and increase profits for businesses.

Benefits of DA200 for flying shear systems:

- High synchronization capability, flexible and precise position control.

- Intelligent operation system, easy adjustment of various cutting modes, convenient for changing orders.

- Maximum cutting productivity, reduced downtime.

- Cutting line capability improves cutting accuracy, eliminates waste.

View detailed solution here: What is Electronic CAM (ECAM)? Applications of ECAM in automation

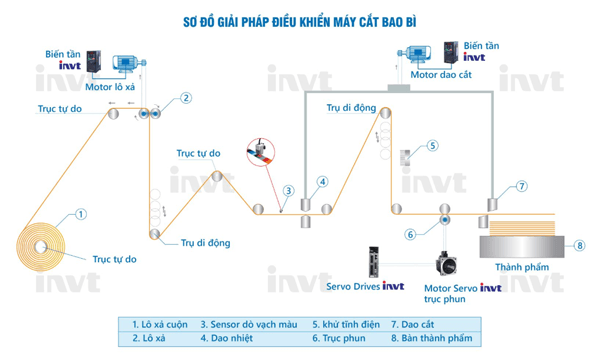

- Nylon Bag Cutting Machine System

The bag cutting machine system is controlled through a PLC programming unit combined with HMI and AC servo DA200, ensuring stable machine operation, precise cutting, uniform and beautiful products up to 130 pieces/minute. The solution helps users easily change the speed and length of products according to production needs.

Benefits of DA200 for bag cutting systems:

- Easy adjustment of machine speed and product length.

- Simple operation system.

- High system performance.

- Smooth operation, uniform, beautiful, and high-quality products.

View detailed solution here: Precise control solution, enhancing efficiency for nylon bag cutting machine

- Packaging Machine System

The packaging machine control solution using PLC/HMI and AC servo motors increases operating efficiency by 30%, with a stable system operation, high precision, easy adjustment of product dosage, and packaging size.

Benefits of DA200 for packaging machines:

- Synchronous operation of components, smooth operation without vibration.

- High speed, fast response frequency with a response frequency of up to 2.0kHz.

- Precise position, speed, and torque control, accurate cutting system, cutting error below 0.5mm, dosing error of about 2%.

- Automatic speed adjustment when mechanical parts wear out.

- Easy to store and change product specifications and dosages.

View detailed solution here: Solution utilizing servo to enhance productivity for automatic packaging machine

- Printing Machine Application

For printing machines, to achieve beautiful, high-quality prints, the linear speed (meters per minute) of the main axis must be synchronized with the speed of the incoming material. At the same time, the length of the substrate to be printed must be accurate. With its outstanding features, the DA200 can address this issue and is used in various printing machines such as offset printers, gravure printers, flexographic printers, silk screen printers, etc., in many different industries.

Benefits of DA200 in printing machine systems:

- Synchronization with the main axis system.

- Placing the product in the correct position, ensuring precise printing.

- High printing speed, low error rate, beautiful printed products, reduced waste.

- Increased productivity of the system.

View detailed solution here: Solution controlling to increase efficiency and accuracy for flexo machines

Additionally, the AC Servo System DA200 is widely applied in many other industries such as rotary plating machines, filling machines, labeling machines, embroidery machines, pipe cutting machines, sawing machines, winding machines, etc.

The AC Servo System DA200 by INVT is supplied directly and exclusively by DAT in the Vietnamese market.

DAT Technology Co., Ltd. (DAT) proudly stands as a leading provider of products, solutions, and services in the Vietnamese market for variable frequency drives, automation, elevator control, and solar energy.

- With over 14 years of experience in developing automation solutions, DAT has sold 500,000 products to over 7,000 customers nationwide.

- With a team of over 350 talented and experienced engineers

- DAT ensures prompt delivery and cost-saving technical support through a large inventory of variable frequency drives up to 1000kW and a nationwide technical service network available 24/7.

- The flexible process of “Replace first, formalities later”.

- DAT is a comprehensive strategic partner with the technology conglomerate INVT, collaborating from research and testing to product and solution introduction to the market.

- By deeply understanding and mastering technology, DAT optimizes processes, solutions, and services.

- DAT provides technical training programs, technology understanding, and machinery upgrade consultancy for customers.

For more detailed information, please visit www.dattech.com.vn and call the toll-free HOTLINE 1800 6567