Applications of Servo Motors in Industry

With numerous outstanding features, high performance, precise control over position, speed, tension, robust operation, and long-term stability, AC servo motor are suitable for a wide range of applications, from basic to specialized and modern, across various industries.

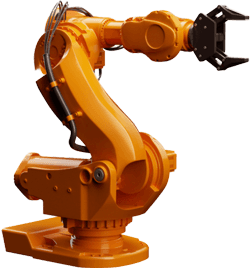

1. Robot Control Applications

2. CNC Machine Systems

3. Face Mask Making Machine Applications

4. Flying Shear and Rotary Cutting Systems

5. Nylon Bag Cutting Machine Systems

6. Packaging Machine Systems

7. Printing Machine Applications

- Robot Control Applications

AC servo systems with precise control over position, speed, and torque provide high work efficiency, robust operation, and stable performance, making them suitable for most robot control systems.

Benefits of AC Servo for Robot Systems:

Simple and user-friendly commissioning. Compatible with all robot joint controllers. Automatic gain adjustment to quickly achieve optimal performance for each joint. AC servo systems enable flexible and precise control of robotic systems. Advanced servo motors like INVT servo DA200 boast position repeatability accuracy of up to ±0.01mm

Related Article: Successful Application of Servo DA200 for Palletizing Robots

- CNC Machine Systems

With fast response times, high overload capacity, and high position accuracy, AC servo systems enhance the performance of CNC systems in the industry.

Hệ thống máy CNC

Benefits of AC Servo for CNC Systems:

- High response speed.

- High overload capacity and rigidity ensure stable operation even at high or low speeds and under heavy loads.

- Full closed-loop control function enhances accuracy and reliability.

- Face Mask Making Machine Applications

Controlling the production of medical face masks solution, using PLC, HMI, and AC servo increases productivity and efficiency, addressing customer manufacturing challenges effectively.

Benefits of the Solution:

High machine speed. Ensures synchronous speed between mechanisms and production stages. Easy control and operation with Vietnamese language display. For face mask making applications, servo motors with integrated CANopen communication like DA180, DA200, are recommended for fast data transmission, eliminating system noise from high-frequency waves, thus increasing productivity and product quality.

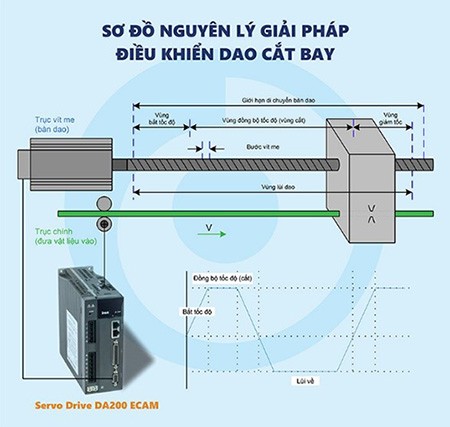

- Flying Shear and Rotary Cutting Systems

Flying shear (or cutoff) is a common application in the industry for continuous cutting of products to pre-set lengths at conveyor speeds. Using AC Servo Ecam – Flying Shear solutions to control flying shear and rotary cutting systems helps customers master the technology, overcome difficulties, and increase profits for their businesses.

Benefits of Servo for Flying Shear Systems:

- High synchronization capability, flexible and accurate position control.

- Intelligent operation system, easily adjustable for various cutting modes, convenient for changing orders.

- Maximize cutting productivity, reduce machine downtime.

- Strip cutting capability improves cutting accuracy, eliminates waste.

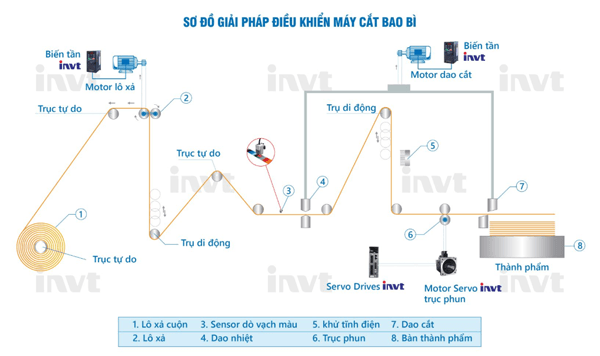

- Nylon Bag Cutting Machine Systems

Nylon bag cutting machine systems are controlled through PLC programming combined with HMI and AC servo, ensuring stable operation, precise cutting, uniform, and high-quality products. The solution enables users to easily adjust the speed and length of products to suit production needs.

Benefits of the Solution:

- Easily change machine speed and product length.

- Simple operation system.

- High system efficiency.

- Smooth operation, uniform, high-quality products with high efficiency motors, minimizing maintenance time and costs.

Read more about: Precise Control Solutions to Increase Efficiency for Nylon Bag Cutting Machines

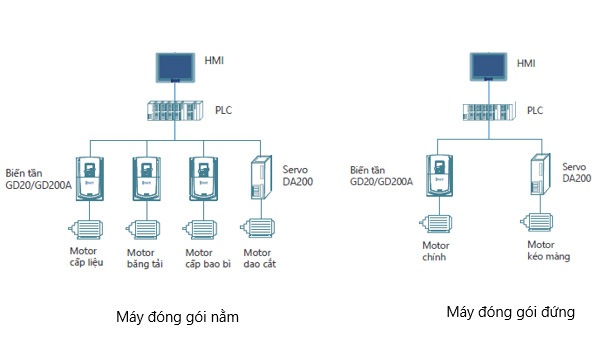

- Packaging Machine Systems

Controlling packaging machines using PLC/HMI and AC servo motors increases operational efficiency by 30%, ensuring stable operation with high accuracy, easy adjustment of dosage and product packaging size.

Benefits of AC Servo for Packaging Machines:

- Synchronized operation of all parts, smooth, no vibration.

- High-speed operation, fast response frequency up to 2.0kHz.

- Precise position, speed, and torque control, accurate cutting system with cutting error below 0.5mm, dosage error of about 2%.

- Automatic speed adjustment for worn mechanical parts.

- Easily store and change parameters, product size, and dosage.

- Printing Machine Applications

For printing machines to achieve high-quality, precise printing, the main shaft speed (meters/minute) must be synchronized with the material speed entering. At the same time, the length of the printing bag must be accurate. With outstanding features, AC servo can solve this problem and is used in various printing machines such as offset, gravure, flexo, and silk screen printing across different industries.

Benefits of AC Servo in Printing Machine Systems:

- Synchronization with the main shaft system.

- Accurate product positioning for precise printing.

- High printing speed, low error rate, beautiful printed products, reduced waste.

- Increased system productivity.

With over 14 years of experience in automation and the trust of over 7,000 customers, DAT is confident as a large-scale, reliable supplier of genuine products along with specialized solutions, ensuring timely response to all needs and delivering the highest efficiency for customers. For more information and consultation, please contact the hotline 1800 6567 (free call).

Related Posts: