Special Features of GD5000 Medium Voltage Inverter

GD5000 is a new generation medium-voltage inverter produced by the INVT technology group, featuring many specialized features for medium-voltage motors. The GD5000 inverter applies a series power unit technique, combining 3-core DSP+PFGA+ARM technology for control systems and the most advanced SVPWM space vector control technology for highly accurate speed control results.

GD5000 medium-voltage inverter

GD5000 medium-voltage inverter

Notable Features of GD5000:

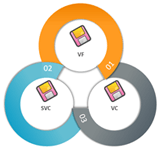

1. Diverse control modes:

|

|

|

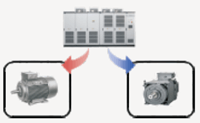

2. Control of multiple motor types: Can control both synchronous and asynchronous motors, easily switchable between the two by changing settings. |

|

3. Four-quadrant control:

- IGBT flow control and energy regeneration technology

- Large power regeneration capability.

- Independent flow control and inverter control.

- Each power unit independently locks phase.

- Strong adaptability to power grid fluctuations.

|

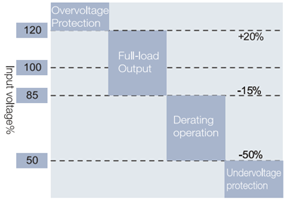

4. LVRT – Low Voltage Ride Through operation: – Strong capability to resist power grid fluctuations.

– Continues to run even during power grid loss for 1s to 5s. |

|

|

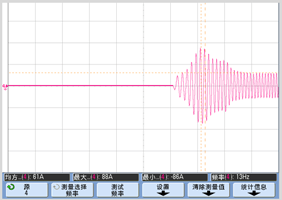

5. Speed tracking function: Motor speed tracking function and recovery of running status in both dynamic and static modes. |

|

|

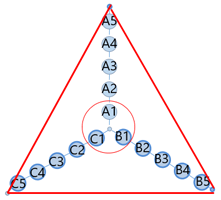

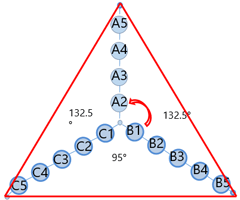

6. Bypass Unit Functionality: – Parallel Bypass:

|

|

– Neutral Point Bypass:

|

|

7. Low-frequency control function:

|

|

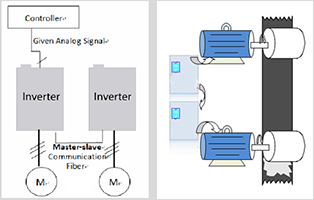

8. Master-Slave control:

|

|

|

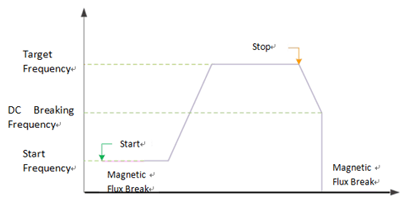

9. Outstanding Braking Performance: – Electromagnetic Braking Technology: Suitable for abrupt stopping applications or applications where external rotational force impacts the load before starting. – Dual-frequency Braking Technology: Capable of generating powerful torque, significantly reducing stopping time, suitable for short braking periods. |

|

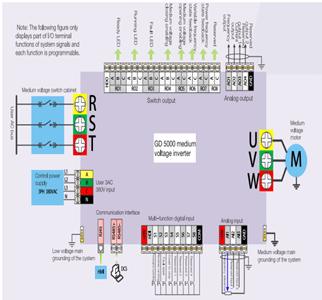

10. Flexible expansion design:

|

|

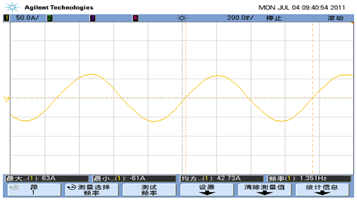

11. Flexible switching:

- Flexible switching between grid power and inverter power.

- Low current impact during switching.

|

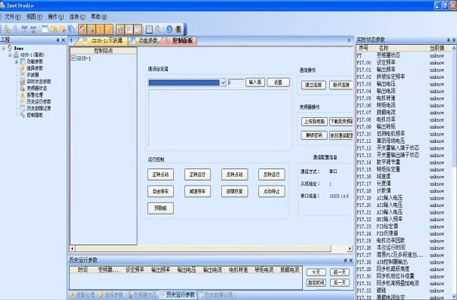

12. User-Friendly Operation Interface: – Large Storage Memory: Records the status of the unit, the inverter, error logs, and stores waveform charts. – Error History Logging Function: Automatically stores current, voltage, and other parameters when the inverter encounters an error during operation, storing the current waveform, accessible via PC software for accurate analysis of the cause of the malfunction. |

|

13. Other functions:

|

|

Diverse Applications in Industry:

The GD5000 medium-voltage inverter is a versatile product suitable for various industrial applications. It is commonly used in heavy industries such as:

|

Thermal Power Forced Draft Fans (FD), Induced Draft Fans (ID), Primary Fans, Secondary Fans, Water Pumps, Circulation Pumps, System Pumps |

Mining Operations Coal Conveyors, Hoists, Air Compressors, Air Blowers, Suction Pumps, Main Fans |

|

Metallurgical Industry High Furnace Blowers, Roaster Blowers, Circulating Pumps, Dust Extraction Fans, Rolling Mill Shafts |

Petrochemical Industry Main Pipeline Pumps, Oil Well Pumps, Intermediate Pumps |

|

Cement Industry: Hot Air Fans, Dust Collection Fans, Ball Mills, Grinding Shafts |

Water Supply Submersible Pumps, Clean Water Pumps, Wastewater Pumps, Oxygen Blowers |

|

Chemical Industry Nitrogen Compressors, Gas Blowers, Circulation Pumps, CO2 Compressors |

Other Industries Paper Industry, Pharmaceuticals, Fans, Pumps, Sugar Cane Industry: Cutting Knives, Press Shafts |

Currently, DAT has successfully applied the GD5000 medium-voltage inverter to various clients, such as controlling coal hoist and conveyor systems at Công ty than Quang Hanh – Quảng Ninh, controlling the speed of Venturi fans – Công Ty Thép Hòa Phát… DAT is the sole distributor in Vietnam to distribute INVT inverters GD5000 with the necessary qualifications to receive the genuine product warranty policy from INVT. In addition to ensuring product quality, DAT also researches specialized solutions to help optimize the efficiency of customer projects.

DAT Technology Co., Ltd. (DAT) proudly stands as a leading provider of products, solutions, and services in the Vietnamese market for variable frequency drives, automation, elevator control, and solar energy.

- With over 14 years of experience in developing automation solutions, DAT has sold 500,000 products to over 7,000 customers nationwide.

- With a team of over 350 talented and experienced engineers

- DAT ensures prompt delivery and cost-saving technical support through a large inventory of variable frequency drives up to 1000kW and a nationwide technical service network available 24/7.

- The flexible process of “Replace first, formalities later”.

- DAT is a comprehensive strategic partner with the technology conglomerate INVT, collaborating from research and testing to product and solution introduction to the market.

- By deeply understanding and mastering technology, DAT optimizes processes, solutions, and services.

- DAT provides technical training programs, technology understanding, and machinery upgrade consultancy for customers.

For more detailed information, please visit www.dattech.com.vn and call the toll-free HOTLINE 1800 6567