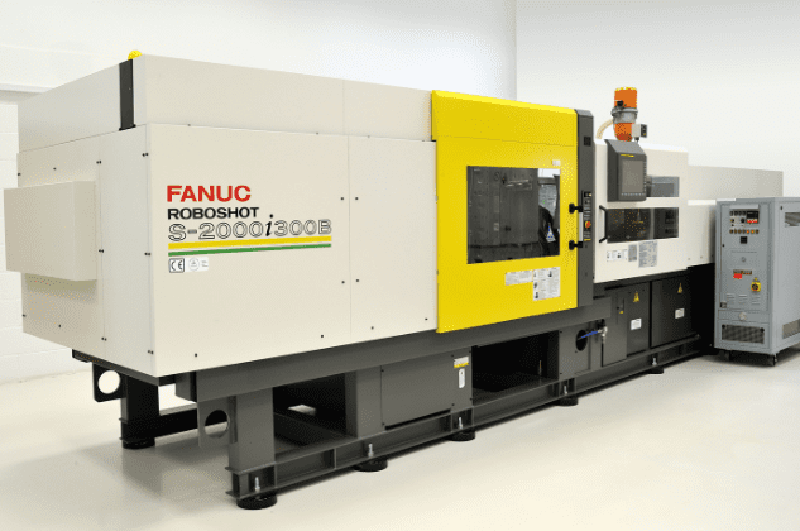

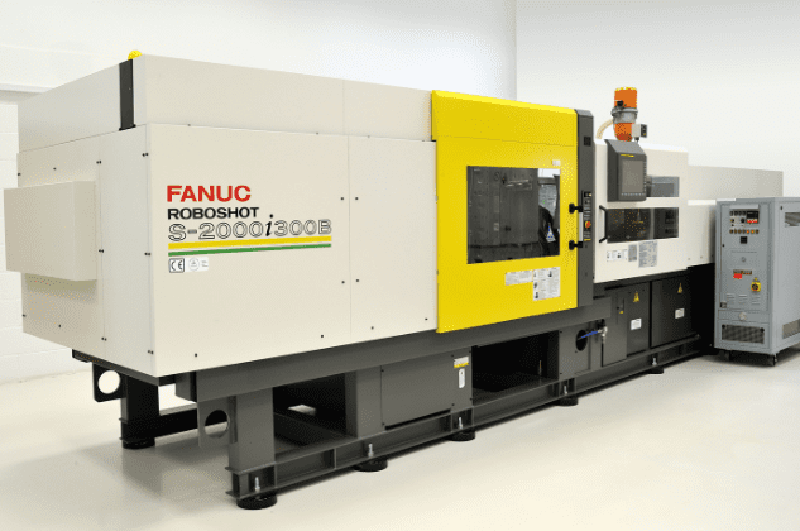

The international ISO standard plastic injection company chooses DAT as a long-term automation partner

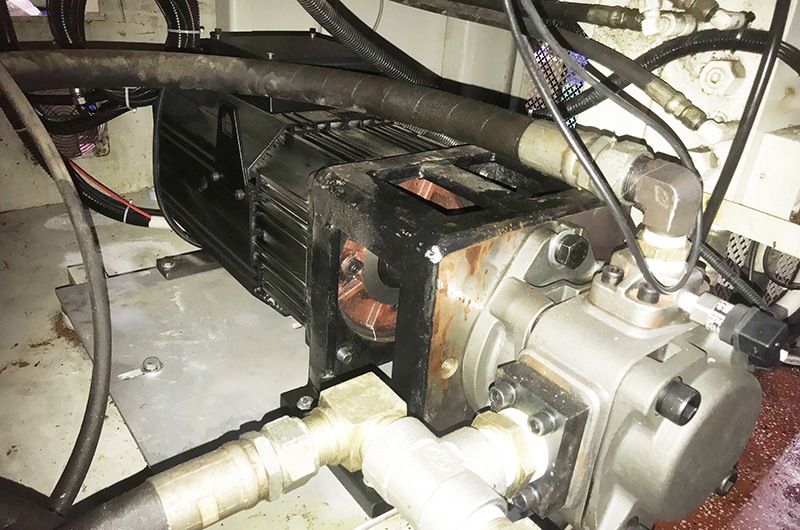

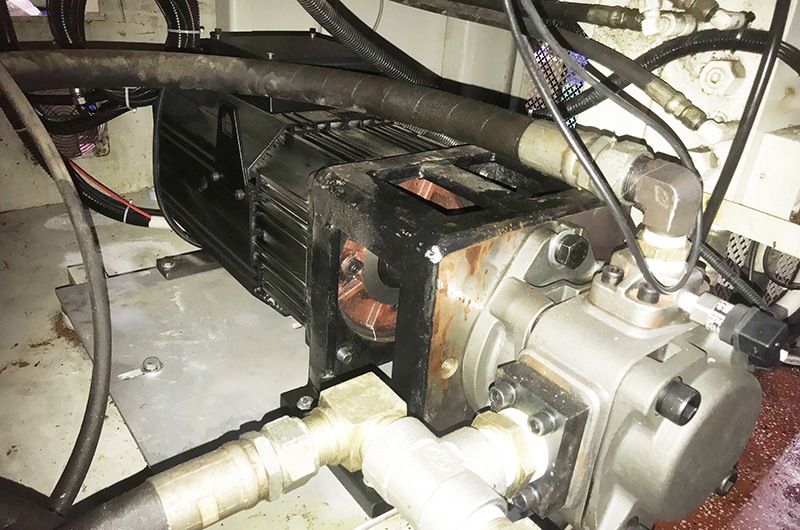

MIDA decided to cooperate with DAT to install the MH800 servo control system to replace the old servo set to thoroughly solve the problem of delayed technical support from the old supplier when the system crashes, causing damage to the company in the production process.

Project information

| Name of client | Mida Precision Mold Co., Ltd |

| Field of activity | Produce plastic molding and technical plastic components |

| Customer need |

|

| DAT’s solutions |

|

| Application results |

|

Other applications:

Successful installation of the medium-voltage GD5000 VFD has led the business to make a second investment, recognizing the high efficiency it offers

View more

DAT Group collaborates in manufacturing a flying cutting system that meets export standards

View more

Application of GD5000 medium-voltage VFD to control oxygen blowing fan in Tuyen Quang steel plant

View more