Standing side by side with Dong Phu Company to overcome the challenges posed by Covid-19

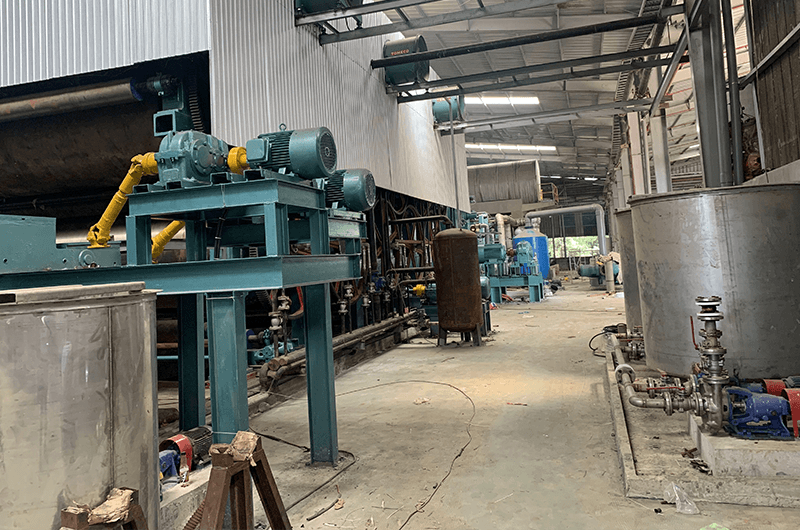

Over the past several months, Covid-19 pandemic has posed numerous challenges and disrupted business operations. To adapt to new situation, DAT quickly implemented remote support solutions through online platforms to assist businesses. With careful preparation, once lockdown measures were lifted, DAT successfully improved paper rolling system at Dong Phu Paper Company (Binh Phuoc), optimizing costs, enhancing operational efficiency, and increasing competitiveness in the new normal state.

Project information

| Customer’s improvement needs | Customer’s Issue | Solutions | Application results |

| Paper Rewinding System |

|

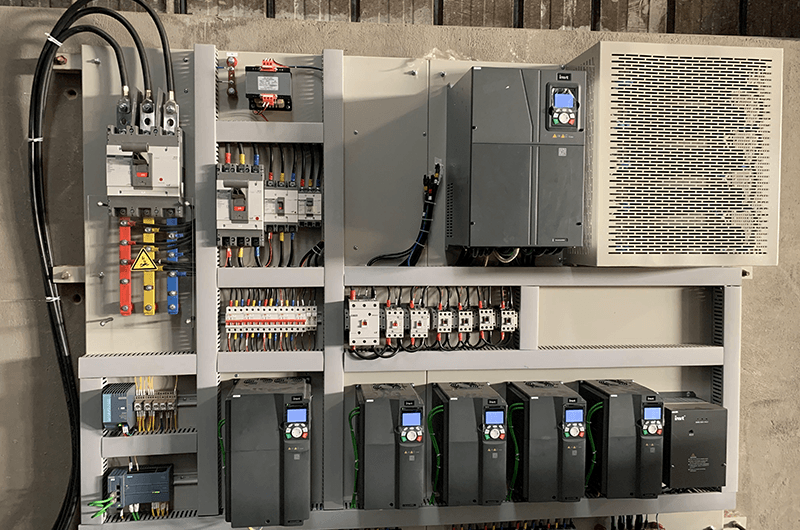

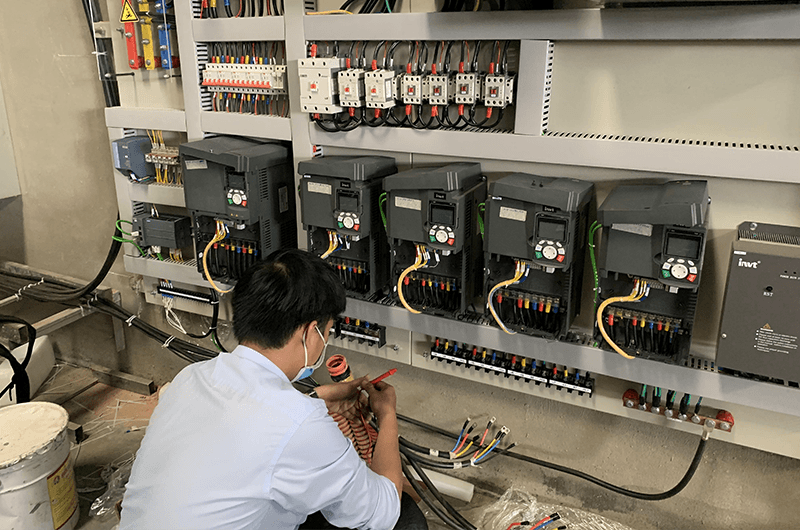

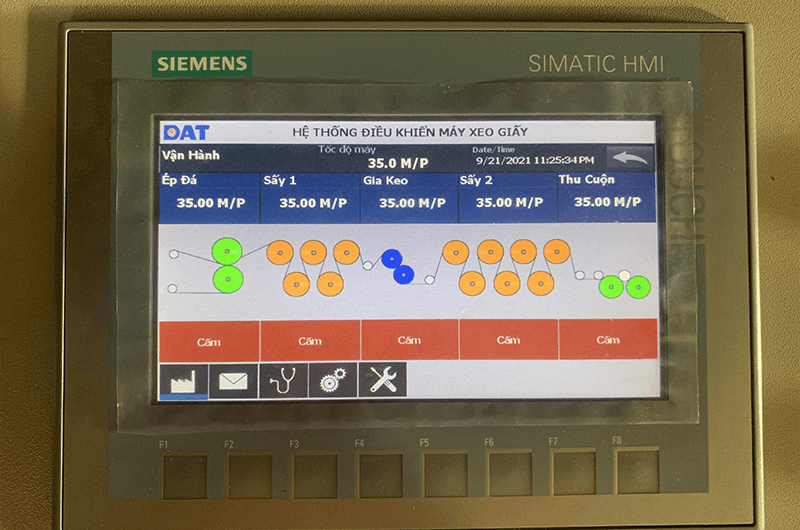

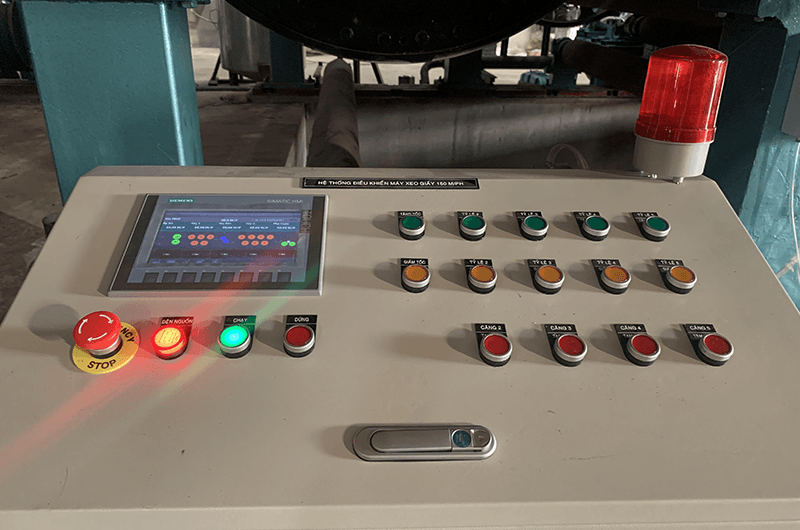

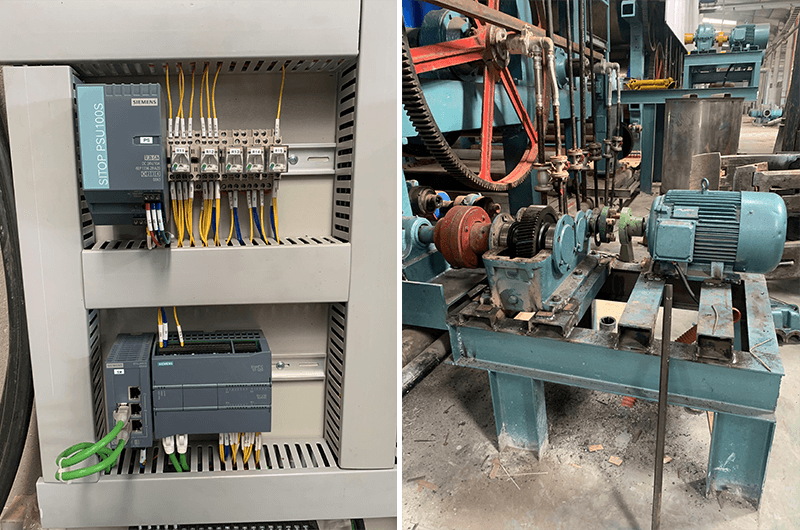

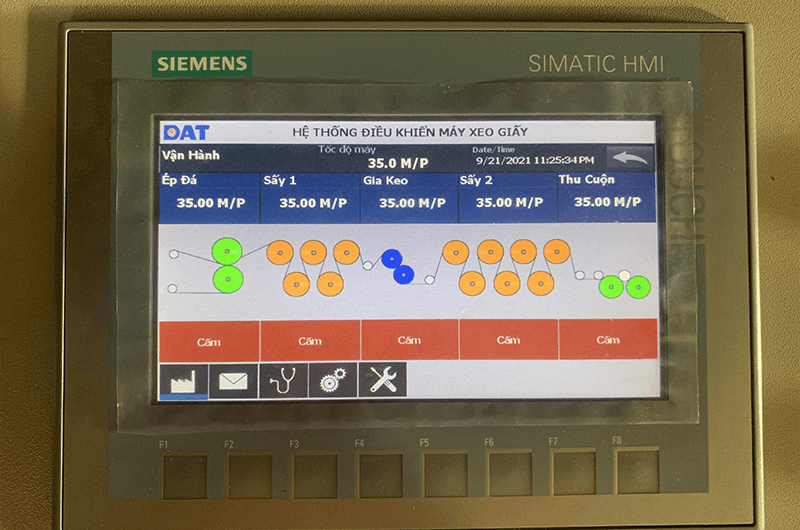

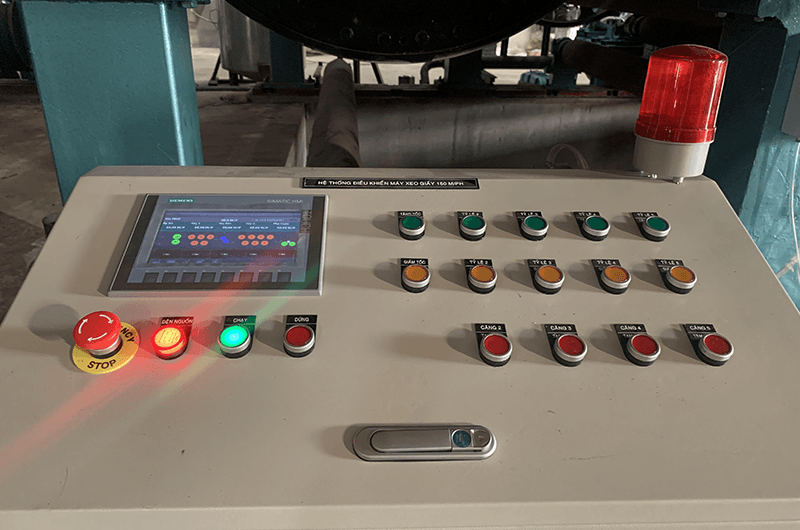

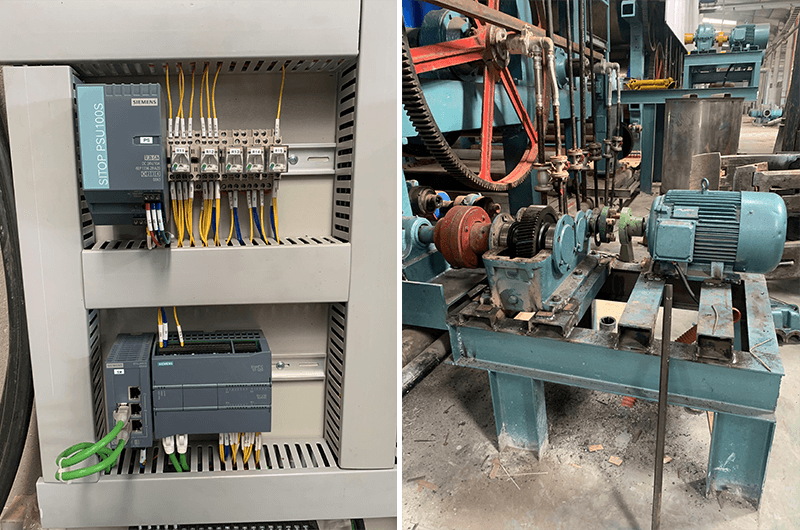

High-Speed Paper Rewinding System Control Cabinet

Configuration includes equipment from both INVT and Siemens:

|

|

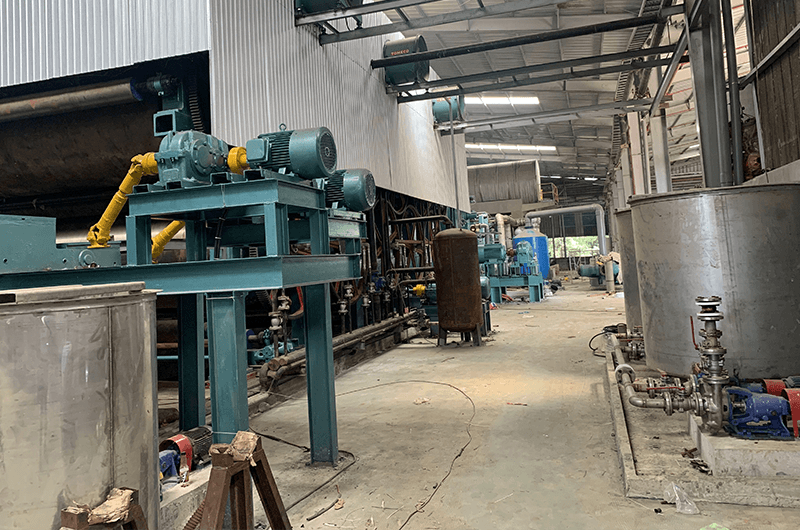

| VACUUM PUMP AND POWDER PUMP SYSTEM |

|

Installation of an electrical control cabinet for variable speed control of vacuum pump and slurry pump system (210kW):

|

|

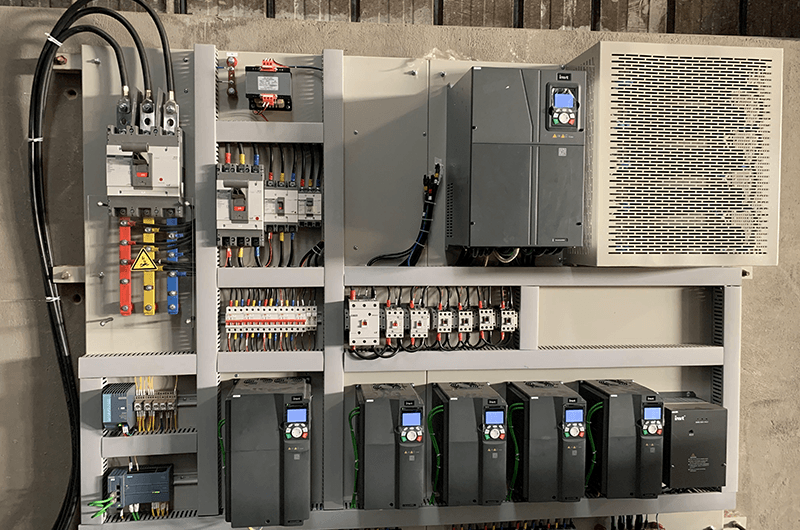

| Steam Boiler Control System |

|

Installation of electrical control cabinet for boiler system (125kW)

|

|

In the past period, Dong Phu Paper Company in Binh Phuoc province reevaluated its capabilities and ability to cope with market fluctuations, thus deciding to carry out digital transformation and continue to restructure its paper mill technology. Exploring various aspects, Dong Phu found “key” to increasing efficiency and enhancing competitiveness in market through automation solutions provided by DAT.

“Previously, DAT provided Dong Phu with a solution to control synchronized high-speed paper cutting system at 120m/min. Throughout this time, system has operated stably, with high performance, delivering high-quality products, minimizing waste, and effectively saving electricity. With array of values DAT has brought, when need arose to expand production scale by implementing a 160m/min paper cutting system to enhance competitiveness in market, Dong Phu immediately chose DAT to continue this project. Despite disruptions caused by pandemic, DAT made efforts to complete project on schedule. Dong Phu highly appreciates professionalism of DAT team,” shared a representative from Dong Phu.

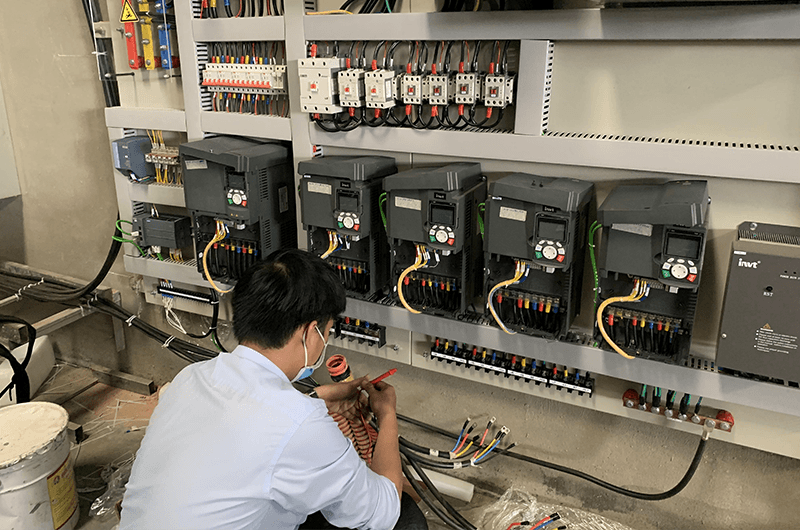

As DAT began project, pandemic erupted, with social distancing measures being issued, making it impossible to physically travel to Dong Phu’s paper mill in Binh Phuoc. Leveraging a comprehensive value ecosystem, DAT overcame this difficulty by providing remote support to customers through online platforms. With over 17 years of experience in automation, DAT’s engineers quickly identified challenges faced by Dong Phu’s paper mill and devised solutions. As a result, when social distancing measures were lifted, DAT immediately successfully improved paper mill, enabling Dong Phu to optimize costs, operate efficiently, and enhance competitiveness in new circumstances.

DAT has been and is striving to overcome challenges posed by Covid-19 pandemic, working hand in hand with businesses to revive economy through specialized solutions in areas such as automation, solar energy and energy storage, elevator control, and UPS.

For all consultation and support needs, please contact hotline 1800 6567 (toll-free). DAT commits to accompanying you 24/7.

Other applications:

Successful installation of the medium-voltage GD5000 VFD has led the business to make a second investment, recognizing the high efficiency it offers

View more

DAT Group collaborates in manufacturing a flying cutting system that meets export standards

View more

Application of GD5000 medium-voltage VFD to control oxygen blowing fan in Tuyen Quang steel plant

View more