Solutions to improve efficiency and precision for circular knitting machines

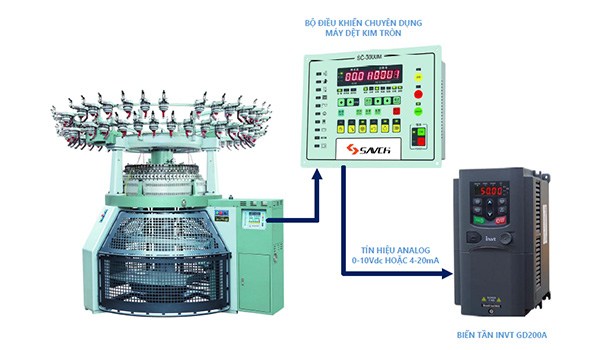

The solution of using INVT GD200A 3P 380V inverter to control the operation of the main motor, suitable for each type of product, replaces the old inverters of the circular knitting machine.

Circular knitting machines perform an important step in the creation of the garments that we use every day. The task of the circular knitting machine is to weave white rustic fabrics before being dyed according to order requirements. Normally, circular knitting machines are imported from abroad, the inverters according to the machines have outdated technology, some machines use 3P 220V voltage, which is not suitable for the national grid, which causes some difficulties for customers.

CUSTOMERS’ DIFFICULTIES

- The old inverter according to the machine has outdated technology, does not meet the control requirements, causes difficulties in operation and reduces production productivity.

- Technical service of the old supplier does not meet the requirements, the inverter is not available or has been discontinued, the delivery time, long installation affects the factory’s production schedule

- Some old inverters use 3P 220V voltage, high cost, almost unavailable and not suitable for the national grid, must use more transformers to convert power

SOLUTION ANALYSIS

DAT deploys the use of INVT’s GD200A inverter to control the main motor suitable for each type of product, replacing the old inverter.

The inverter controls the motor to run at different speeds:

- Run at low speed about 10Hz when starting the machine, high pulling torque required

- Run at steady speed up to 70Hz, this speed varies depending on the fabric

- Run at 5-7Hz when you need to adjust the machine, insert the thread

SOLUTION ADVANTAGES

- Improve productivity, reduce maintenance

- Stable operation system, improve product quality

- Protect motor and mechanical, avoid needle breakage

- Simple operation system, easy to change orders

- Improving technology suitable for the national grid, eliminating transformers

Take a look at DAT's specialized solution design process.

Contact an expert

If you need advice and learn about DAT’s solutions, please contact 1800 6567 to meet with experts today.

Products for solutions

Solution relate:

10.000+

15+

3000+

24h

Let's go with DAT

24/7 SUPPORT

Hotline 1800 6567