Solution to upgrade and replace control technology for flat knitting machines

Using INVT inverters to replace, upgrade and improve technology for knitting machines, helps the system operate stably, properly serve customer needs and improve product quality.

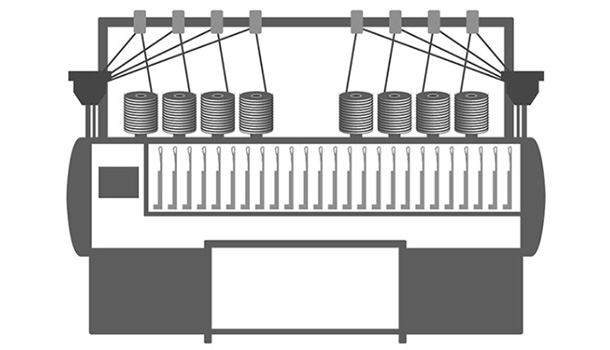

Knitting technology is often applied to the production of outerwear such as sweaters, long coats, short coats, decorative accessories such as collars, sleeves and hats, etc. Most of the current flat knitting machines in Vietnamese factories are imported abroad, divided into 2 types:

- Old knitting machines: using old technology, with a small motor running at low speed for feeding the fabric and handling when a problem and a large engine run at high speed.

- Modern knitting machines: only 1 motor is controlled by inverter. The machine has a dedicated PC controller and an HMI monitor that monitors and adjusts to different weaving programs

CUSTOMERS’ DIFFICULTIES

- For old knitting machines: Outdated control solution, low productivity, motor not starting smoothly, easy to cause needle breakage, difficult to change motor speed depending on each order, power loss for orders requiring low speed

- For modern knitting machines: the harsh environment and working conditions can cause damage to the inverter. However, dedicated inverters are not available, expensive prices, and long delivery times causing order delays

SOLUTION ANALYSIS

The DAT solution uses a single INVT GD200A inverter and a single motor to drive the flat knitting machine, eliminating the low running motor by changing the motor speed by inverters but still ensuring the old operation. The GD200A inverter is also suitable for replacing the old inverter of the factory quickly, ensuring the production schedule.

SOLUTION ADVANTAGES

- Improve technology, use only a single engine

- Smooth start, same operation

- Easily adjust the motor speed depending on the order

- Save energy with orders that need low speed

- Productivity can be increased by increasing engine speed

- Complete solution, fast delivery, quick and easy installation. 24/7 service

Take a look at DAT's specialized solution design process.

Contact an expert

If you need advice and learn about DAT’s solutions, please contact 1800 6567 to meet with experts today.

Products for solutions

Solution relate:

10.000+

15+

3000+

24h

Let's go with DAT

24/7 SUPPORT

Hotline 1800 6567