Solution to increase efficiency for JET dyeing machine

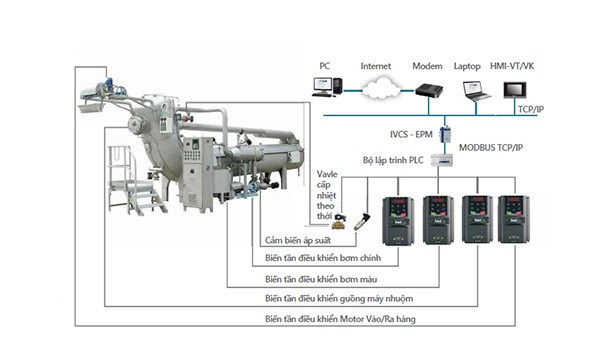

DAT uses a PLC programmer as a central controller, connected to the Internet, making it easy for the factory to control the entire Jet dyeing machine system, monitor, diagnose errors and quickly handle problems remotely. In addition, controlling the main motors by INVT inverter helps to protect the motor, mechanical system, save power and increase system’s lifetime.

JET dyeing machine is a closed dyeing device, operating on the principle that the goods and the solution move together, because it is a high-pressure machine, it is often dyed with disperse dyes at high temperature and pressure, operating according to the intermittent method to soften and reduce weight. The old-style operating method, the cloth feeding motor and the circulation pump motor are all started directly through the mains grid, the reel motor is a DC motor, and the heating valve system is controlled from specialized units.

CUSTOMERS’ DIFFICULTIES

- Old, outdated technology.

- Cost of maintenance.

- Unstable system.

- Maintenance and upkeep takes a lot of time and money.

- Engines are prone to damage and wear and tear.

- Consumes a lot of power.

SOLUTION ANALYSIS

Each dyeing system uses 01 PLC as the central controller, controlling the entire JET dyeing machine system. Parts such as main pump motor, dyeing machine wheel, fabric feeding motor, etc. are controlled by INVT inverter. The central controller is connected to the internet, making it easy for the maintenance person to remotely diagnose and debug the program. All electrical equipment (inverter, PLC, HMI, etc.) are concentrated in the cold room to help the equipment operate more stably and have a longer lifespan.

SOLUTION ADVANTAGES

- Easily monitor and troubleshoot remotely over the Internet.

- Protects the reel motor when the fabric is jammed.

- Saving electric energy for circulation pump.

- Best pump protection, overcome voltage drop on power lines.

- Resistance to mechanical and pipe wear.

- Complete solution, quick and easy installation. 24/7 service

Take a look at DAT's specialized solution design process.

Contact an expert

If you need advice and learn about DAT’s solutions, please contact 1800 6567 to meet with experts today.

Products for solutions

Solution relate:

10.000+

15+

3000+

24h

Let's go with DAT

24/7 SUPPORT

Hotline 1800 6567