Replace the servo drive of the hydraulic plastic injection machine with a GD350 VFD

Recently, DAT’s R&D engineer team has researched and successfully applied a breakthrough solution to replace the hydraulic plastic injection machine servo driver with the GD350 super inverter at Mida Precision Mold Co., Ltd. The solution helps the factory to keep the old servo motor, just replace the servo driver by GD350 inverter when the system has a problem to save costs, optimize efficiency and reduce machine downtime.

Project information

| Name of client | Mida Precision Mold Co., Ltd |

| Field of activity | Produce plastic injection molds and technical plastic components |

| Customer need |

|

| DAT’s solutions |

|

| Application results |

|

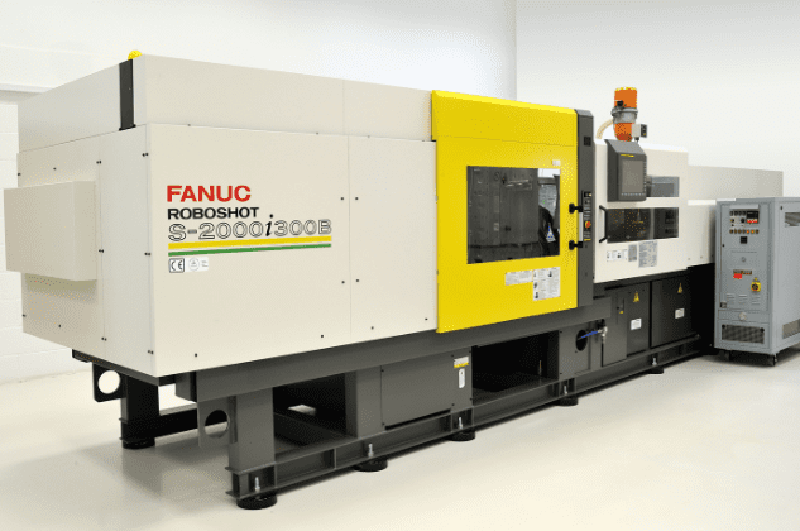

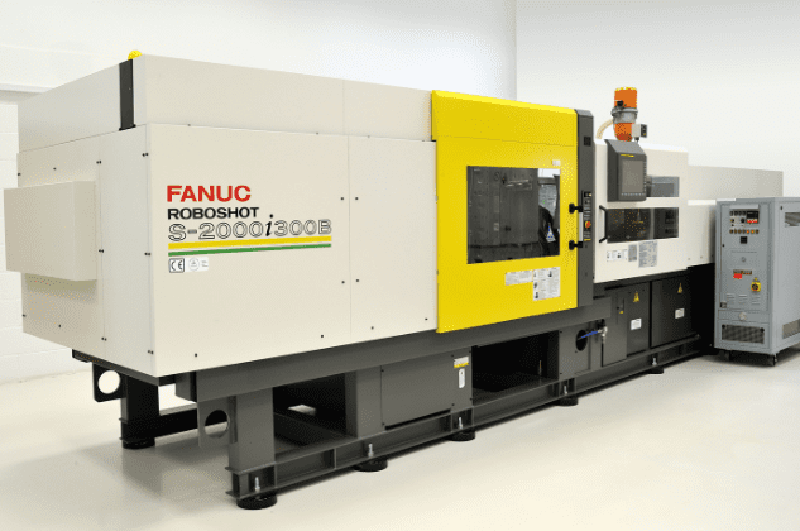

Mida Precision Mold Co., Ltd. meets ISO 13485:2016 and ISO 45001:2018 standards, is a leading enterprise in Vietnam in the field of manufacturing plastic injection moulding and technical plastic components. The factory is located in Ben Luc district, Long An with an area of 25,000m2, controlling and operating over 60 Taiwanese hydraulic plastic injection machines with a total capacity of the whole system estimated at more than 900 kW.

Other applications:

Successful installation of the medium-voltage GD5000 VFD has led the business to make a second investment, recognizing the high efficiency it offers

View more

DAT Group collaborates in manufacturing a flying cutting system that meets export standards

View more

Application of GD5000 medium-voltage VFD to control oxygen blowing fan in Tuyen Quang steel plant

View more