Solution

Solution to save up to 25% electricity for air compressors

The solution of using INVT inverter helps the air compressor to operate stably, smoothly and save from 10% - 25% of power consumption.

Synchronous control solution and enhanced durability for the flying cutter system

The breakthrough solution of Servo SV-DA200 Ecam – Flying Shear synchronous control of flying cutters helps the flying cutter system achieve high accuracy, maximize operational productivity and completely eliminate waste.

Solutions to save energy and improve technology for industrial boiler systems

The solution using INVT's GD20/GD200A inverter to control the motor system in the boiler helps to stabilize the steam flow and pressure, save electricity, and increase the life of the engine.

Solutions for pressure control, rotation and power saving for multi-pump systems

The solution uses INVT's dedicated inverter HVAC GD300-16 to control the multi-pump pressurization system - alternately to ensure stable operation of the pump system, reduce investment costs, save electricity and improve service life. engine.

GD35-09 synchronous integrated cabinet to control the rotary cutter

The GD35-09 synchronous integrated cabinet controls the rotary knife cutter for ideal paper cutting results, with an error of less than 0.5mm, the product is cut sharp, beautiful and uniform with a high speed of up to 350m/ minutes and eliminate 100% of waste due to incorrect cutting. The advanced synchronous integrated control algorithm of the GD35-09 cabinet makes the rotary cutter smooth and sweet, protecting the blade system and the transmission mechanism of the rotary cutter.

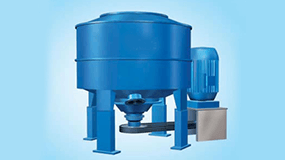

Solutions to save energy and improve the durability of hydraulic paper mills

DAT's solution using INVT's GD200A inverter allows adjusting the motor's speed according to the technological cycle to save power consumption, reduce repair costs and improve the durability of hydraulic paper mills.