Successful installation of the medium-voltage GD5000 VFD has led the business to make a second investment, recognizing the high efficiency it offers

Completely satisfied with product, solution, and service provided by DAT in first project, Lam Thach Company has contacted DAT again to install medium-voltage GD5000 VFD to control ID fans in cement production line. This solution once again completely addresses weaknesses of old system and brings significant economic benefits to Lam Thach.

Project information

| Name of client | Lam Thach Cement Company |

| Location | Quang Ninh, Vietnam |

| Field of activity | Cement manufacturing industry |

| Customer need |

Improvement of ID fan is aimed at addressing limitations of the old system. Previous ID fan system utilized hydraulic couplings and ran directly through a cutting machine with a starting resistor. Air flow was adjusted using damper vanes. As a result, customer incurred significant electricity and maintenance costs, and adjusting the airflow during the production process was challenging. |

| Solution |

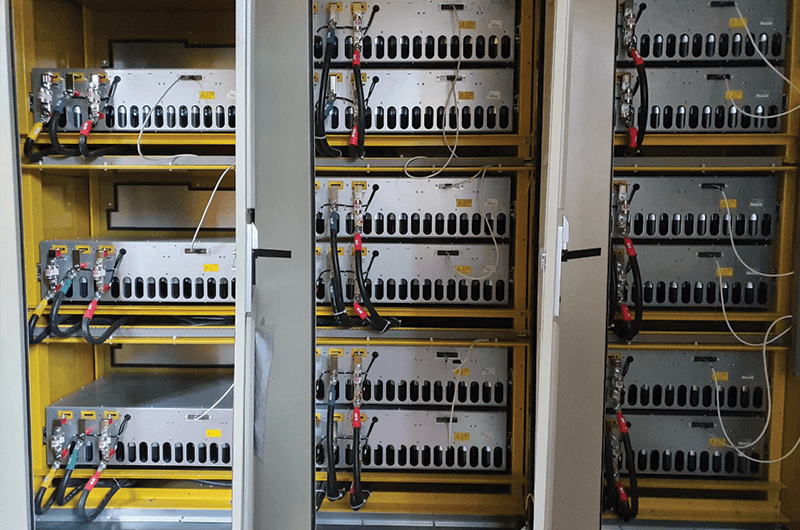

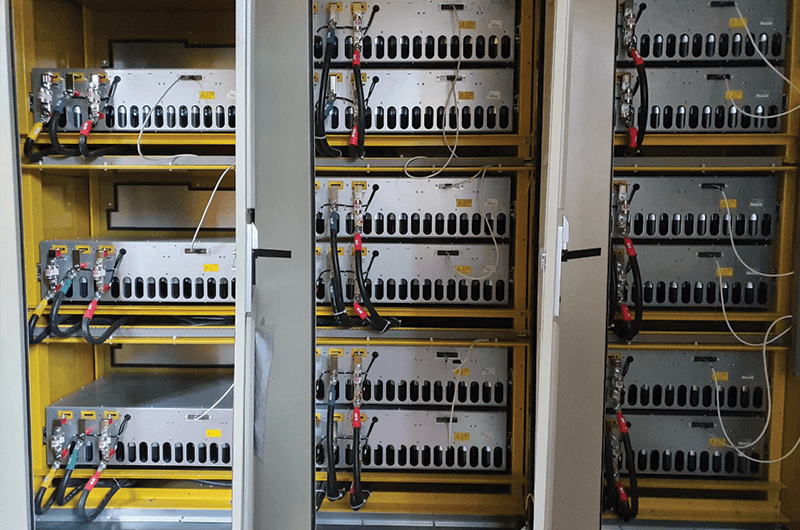

INVT medium-voltage VFD GD5000-A1600-6-S is employed to control ID fan system. |

| Application results |

|

In recent times, increasing production output and optimizing manufacturing processes have become crucial requirements for Lam Thach Cement Company. This need has been further highlighted by fact that company has to halt operations for one month each year for motor, fan, and duct maintenance. A comprehensive assessment revealed that existing ID fan system falls short in terms of suction capacity and adjusting airflow, particularly when kiln system undergoes changes in raw materials and fuel.

In modern cement production technology, ID fan plays a pivotal role and is often referred to as “lungs” of entire clinker production line. ID fan is typically not readily available on domestic market and is mainly imported from abroad. This leads to significant challenges and obstacles during upgrading or maintenance of system, both in terms of time and cost, preventing company from maintaining proactive production.

Given these challenges, finding a capable domestic solution provider to upgrade ID fan system has become a top priority for Lam Thach. DAT has continued to be the optimal choice for Lam Thach due to company’s satisfaction with previous automation solution provided by DAT.

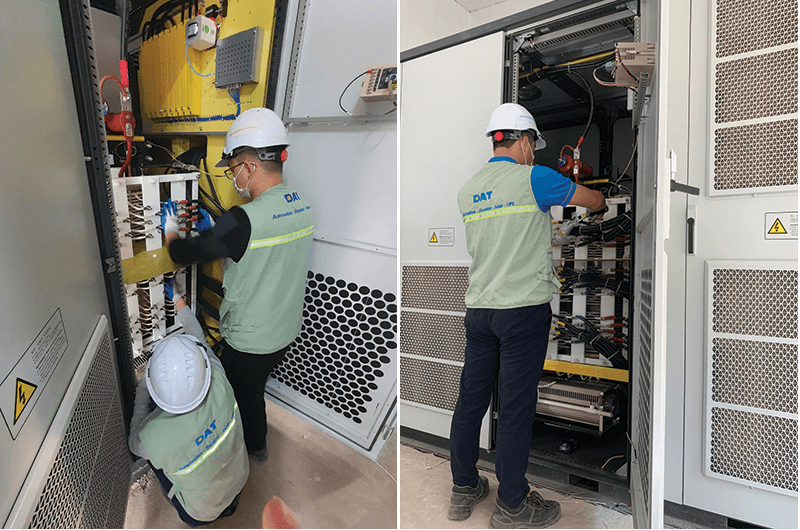

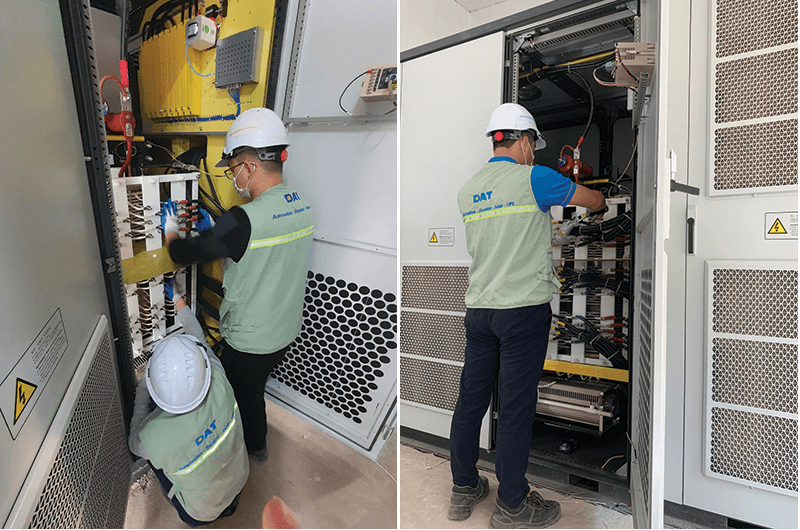

Covid-19 pandemic has placed many entities in difficult positions in terms of securing supply and meeting customer demand for products and solutions. However, with over 17 years of developing and cultivating a robust value ecosystem, DAT possesses superior supply capabilities, diverse product offerings, and efficient delivery processes. This has allowed for swift installation and fulfillment of Lam Thach’s expectations. DAT’s technical team is also available 24/7 and dedicated to knowledge transfer, enabling Lam Thach to take full control of the system and operate with confidence.

Lam Thach’s representative shared with DAT that, based on the value received from two successful solution implementations, company intends to collaborate with DAT on a third project concerning enhancement of electrostatic dust filter fan system.

Other applications:

Successful installation of the medium-voltage GD5000 VFD has led the business to make a second investment, recognizing the high efficiency it offers

View more

DAT Group collaborates in manufacturing a flying cutting system that meets export standards

View more

Application of GD5000 medium-voltage VFD to control oxygen blowing fan in Tuyen Quang steel plant

View more