High efficiency thanks to the application of remote control solution for Jet dyeing machine

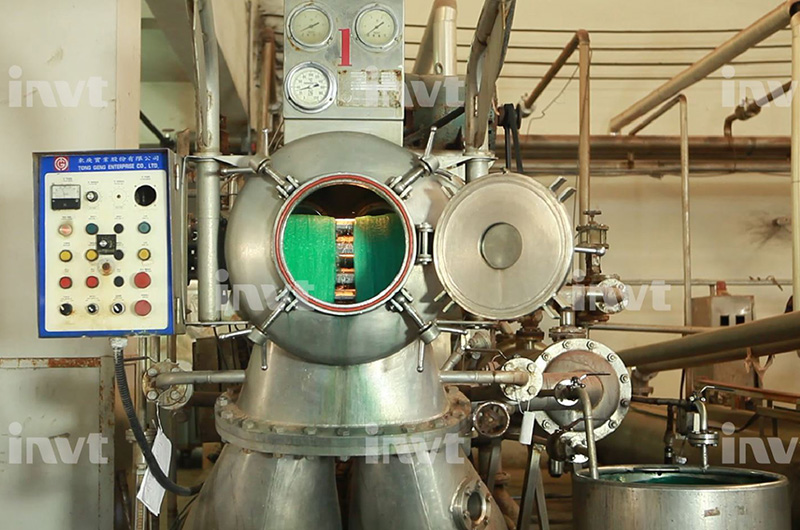

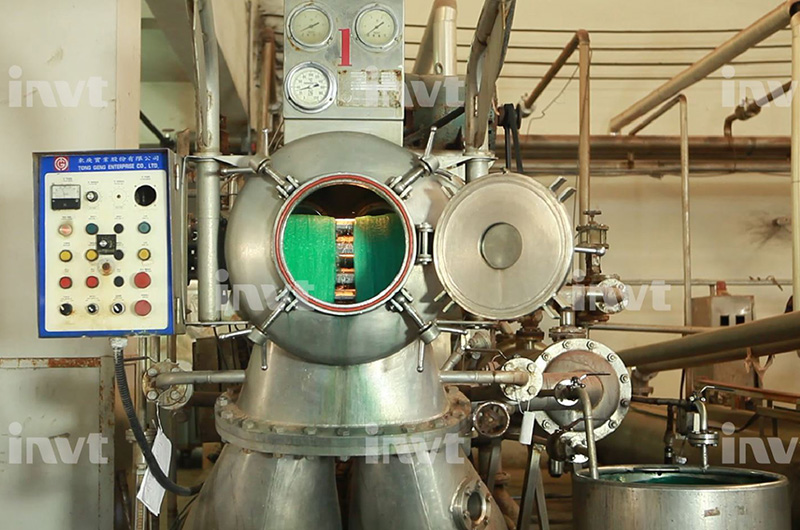

“The solution of DAT Company very well meets the technology for the Jet dyeing system of Kim Thanh Hung company. INVT products operate stably, protect the motor of the machine when the fabric is stuck. In particular, the central controller is connected to the Internet, making it easy for us to diagnose errors and debug programs remotely.”

Mr. Nguyen Khac Phap – Head of Maintenance Department of Kim Thanh Hung Co., Ltd. shared.

Project information

| Name of client | Kim Thanh Hung Co. Ltd. |

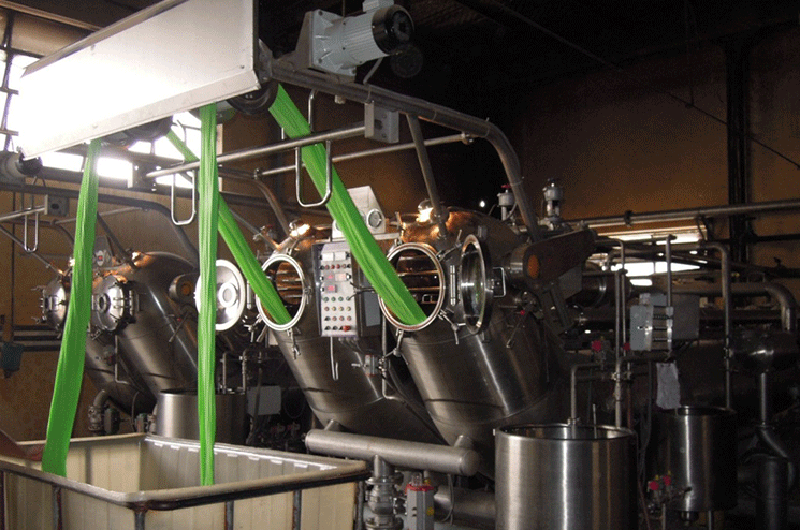

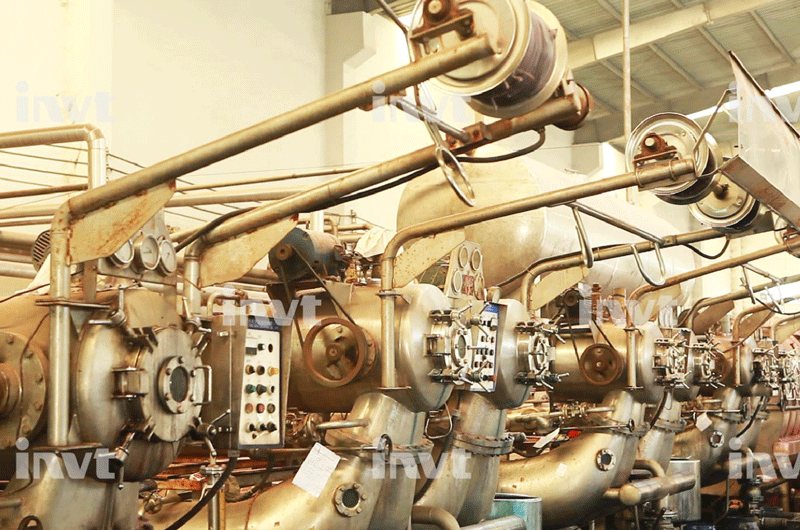

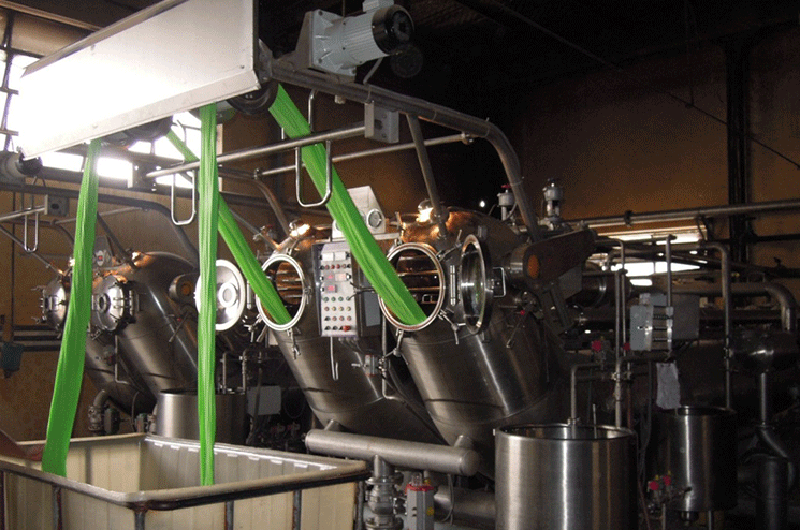

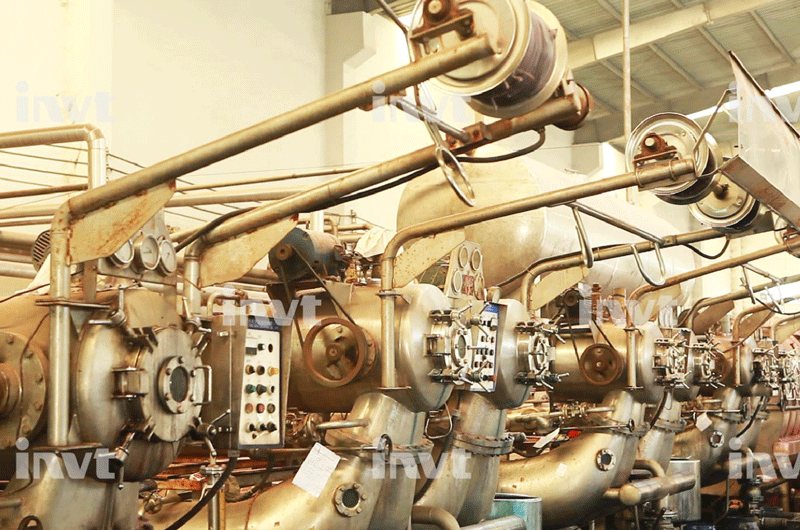

| Field of activity | Weaving and dyeing fabric |

| Customer need | Looking for a technologically responsive control solution for 8 Jet dyeing machines |

| DAT’s solutions | Using 1 PLC as the central controller, controlling the entire Jet dyeing machine system |

| Application results |

|

Other applications:

Successful installation of the medium-voltage GD5000 VFD has led the business to make a second investment, recognizing the high efficiency it offers

View more

DAT Group collaborates in manufacturing a flying cutting system that meets export standards

View more

Application of GD5000 medium-voltage VFD to control oxygen blowing fan in Tuyen Quang steel plant

View more