GD350 – The Most Anticipated Premium VFD of 2019 by INVT

After a long period of research and development, INVT has officially introduced its premium and most anticipated VFD series of 2019 – versatile GD350 VFD. Built upon INVT’s state-of-the-art processing platform and incorporating world-leading vector control technology, along with wireless control capabilities, cloud computing, and IoT integration, this product is aimed at the modern Industry 4.0 manufacturing landscape. It enables users to monitor and update operational status of device from anywhere via tinternet with exceptional precision and absolute safety.

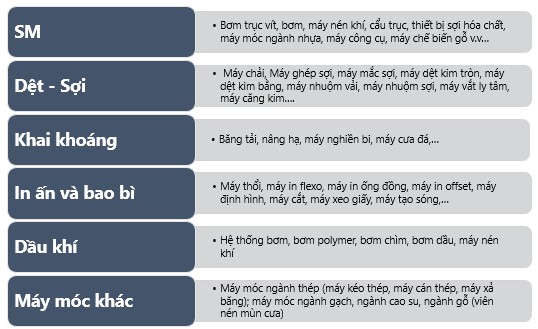

GD350 is poised to revolutionize solution landscape in Vietnam market in near future. It’s a VFD that caters to a wide range of applications, from simple to complex, across various industries. This product is particularly suitable for machine manufacturers and system integrators seeking to program PLCs and customize exclusive applications according to individual client requirements, all at a low cost.

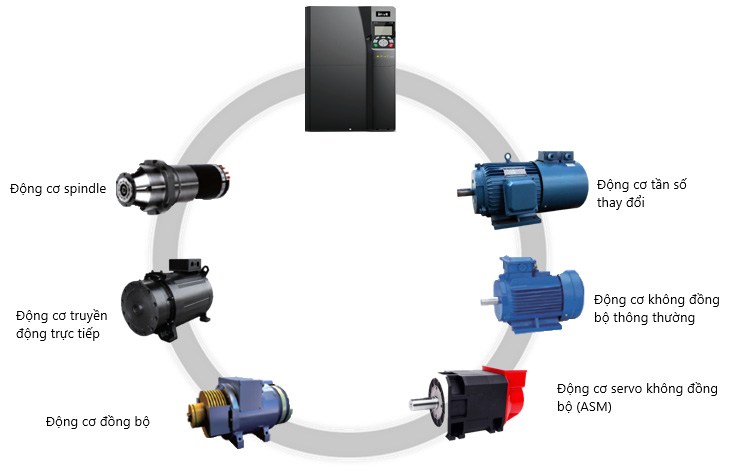

1. Suitable for Various Motor Types

GD350 can control a variety of different motor types: asynchronous motors, asynchronous servo motors (ASM), synchronous motors, direct-drive motors, spindle motors, VFD motors, etc., with high efficiency.

2. Unlimited Expansion Capabilities

In addition to integrated basic features, GD350 also supports various types of expansion cards: PLC cards (128kB), I/O cards, communication cards (with a wide range of communication standards), PG cards, etc.

It’s possible to install 2 expansion cards with VFD power below 5.5kW and 3 expansion cards with power from 7.5kW and above. Expansion card sizes are the same, making installation easy.

≤5.5kw

≥7.5kw

3. Customer-Self Programmable Software Support for Various Applications

INVT GD350 VFD supports optional PLC cards with memory of up to 128kB, convenient for customers who want to program software for diverse applications. This enables customization and self-development of exclusive solutions at a low cost.

Using CODESYS platform, it supports 6 PLC programming languages: IL, ST, FBD, LD, CFC, SFC

4. Support for Various Communication Protocols

Standard Modbus communication (RS485)

Support for optional communication expansion cards, enabling connection via popular communication protocols like Ethernet, CANopen, Profibus DP, Bluetooth, Profinet…

5. Wireless Setup and Editing via Bluetooth

GD350 supports wireless device setup and parameter adjustment via Bluetooth, using a mobile app instead of a traditional keypad. This allows users to calibrate, monitor, and control device easily without need to open control panel. App also supports automatic diagnosis, alerting, and monitoring of device activity.

6. Remote Monitoring of Device Activity

Wireless connection via internet, combined with cloud computing and IoT technology, allows users to monitor and update real-time operational status of VFD from anywhere via mobile devices/computers.

7. Standard USB Protocol Port

Supports standard USB 2.0 protocol (Type A), allowing convenient and fast program downloading to VFD. Operational profile of VFD can be recorded externally, facilitating maintenance and data analysis.

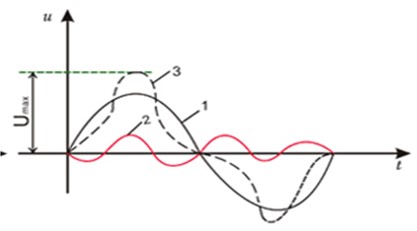

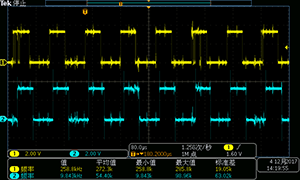

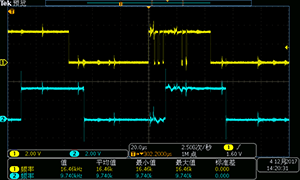

8. Extremely Precise Control Capability

GD350’s unique digital filtering technology allows VFD to achieve more stable and accurate closed-loop control, improving noise filtering capabilities and stable reception of encoder signals over longer distances. Compared to traditional techniques, GD350’s noise immunity is doubled.

Support for various encoder types: relative encoders (5V / 12V / 24V), absolute value, Sin-Cos, rotary transformer, UVW… Support for encoder output ratio settings. Quick error signal detection from encoders, avoiding system-wide impact.

9. 2 HDI Pulse Input Ports

Integrated 2 HDI pulse input ports can be used as speed setting sources and can support high-speed A/B pulse input signals, creating an encoder signal to provide customers with a more economical closed-loop application package instead of using an additional PG card.

10. Safe Torque Off (STO) Function

GD350 integrates STO (SIL2) protection function, complying with international standards, ensuring safer and more reliable operations.

11. LCD Keypad

Multi-language keypad with an LCD screen featuring up to 16 lines of display, including graphical representation. Keypad supports a wizard mode for parameter setup when powered on. Supports storing 3 sets of VFD parameters for upload and download, includes directory navigation, and allows easy monitoring, adjustment, and calibration.

12. Space-Saving Design with Built-In Brake Unit

GD350 supports a pre-designed space for installing a brake unit within VFD (supporting up to 110kW), reducing costs and saving installation space.

Power range 1.5~37kW: Standard built-in brake unit

Power range 45~110kW: Optional brake unit

13. Integrated DC Reactor with VFD Power 18.5kW~110kW

Basic Applications of GD350

Aimed at requirements of modern industrial production, GD350 is equipped with versatile features and limitless expansion capabilities to meet diverse applications across various industries. This product is especially suitable for machine manufacturers and system integrators, meeting needs for self-research, creativity, specialization, and exclusive solutions for various application requirements at a low cost.