GD200A solution for high efficiency spinning machine

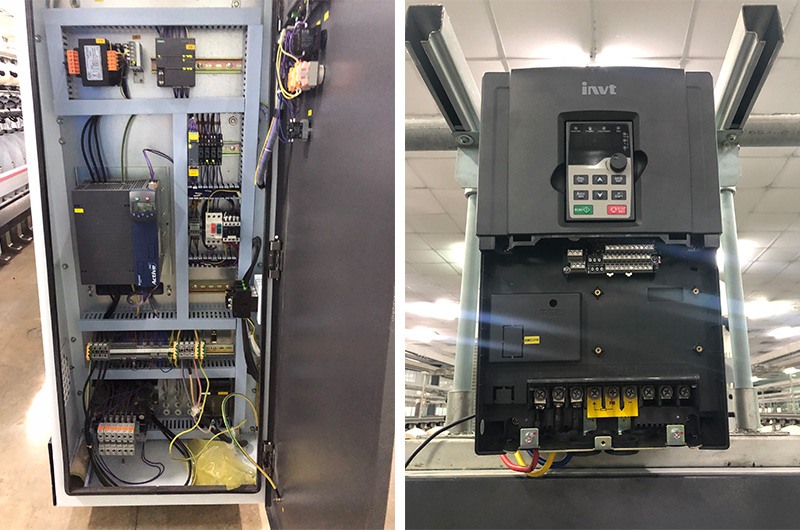

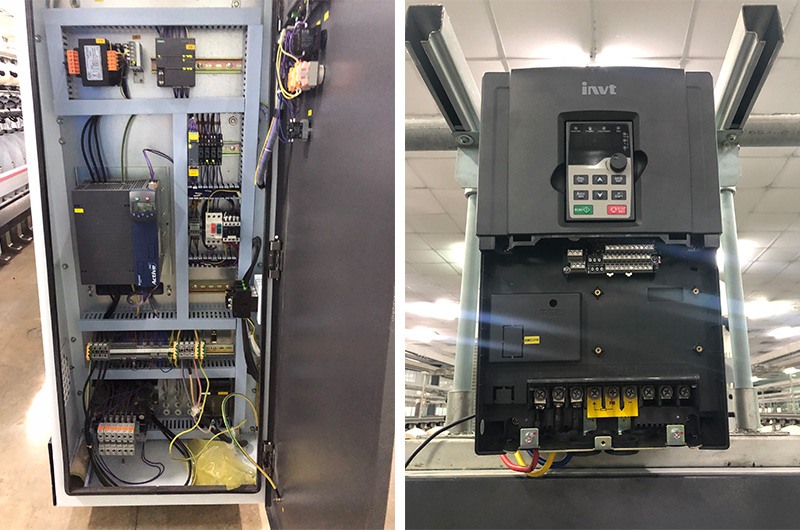

Receiving satisfactory results from 6 GD200A inverter-integrated spinning machines, An Thinh Phat Construction Design Investment Joint Stock Company continued to choose DAT to improve the technology for the remaining 10 spinning machines system. This solution helps the system to start smoothly, easily change speeds and protect the engine in harsh environments.

Project information

| Name of client | An Thinh Phat Construction Design Investment Joint Stock Company |

| Field of activity | Textile industry |

| Customer need |

|

| DAT’s solutions | Use the GD200A inverter to control the spinning machine system. |

| Application results |

|

Low cost – high efficiency – outstanding service

Before using DAT’s solution, An Thinh Phat Construction Design Investment Joint Stock Company used 16 direct spinning machines. The spinning machine is powered by a motor through a mechanical mechanism, pulling the axes synchronously with a belt, the machine length is about 20m. Therefore, when running directly, the star-delta starter motor causes mechanical shock and is very easy to damage the belt, and the repair and replacement cost is quite large.

Assessing that it is urgent to install an inverter to protect the motor and report errors, DAT has applied the GD200A inverter to control the spinning machine to help customers solve difficulties. This solution helps the system to operate stably, smoothly and efficiently with at competitive prices. In addition, the use of GD200A inverter also helps customers easily adjust the system speed to suit each order.

Thanks to high technical expertise, fast installation speed and dedicated system operating instructions, customers have highly appreciated and placed their trust in DAT.

Other applications:

Successful installation of the medium-voltage GD5000 VFD has led the business to make a second investment, recognizing the high efficiency it offers

View more

DAT Group collaborates in manufacturing a flying cutting system that meets export standards

View more

Application of GD5000 medium-voltage VFD to control oxygen blowing fan in Tuyen Quang steel plant

View more