Control solution for RO water purifier system

The cooperation aims to expand the effective solution to many projects, manufacturing plants and farms that need to use RO water purifier systems to create clean water sources across the country shorly soon.

Project information

| Name of client | My Viet Technology and Environment Co., Ltd |

| Field of activity | Producing filtration equipment, water filtration and treatment technology |

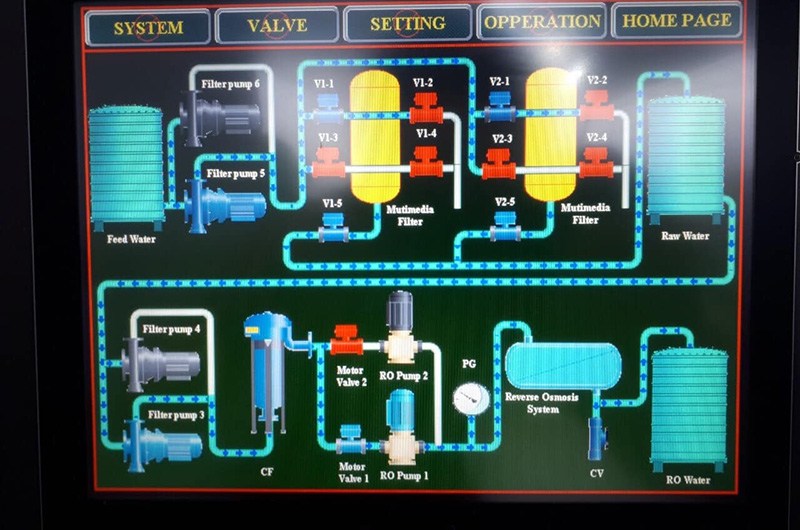

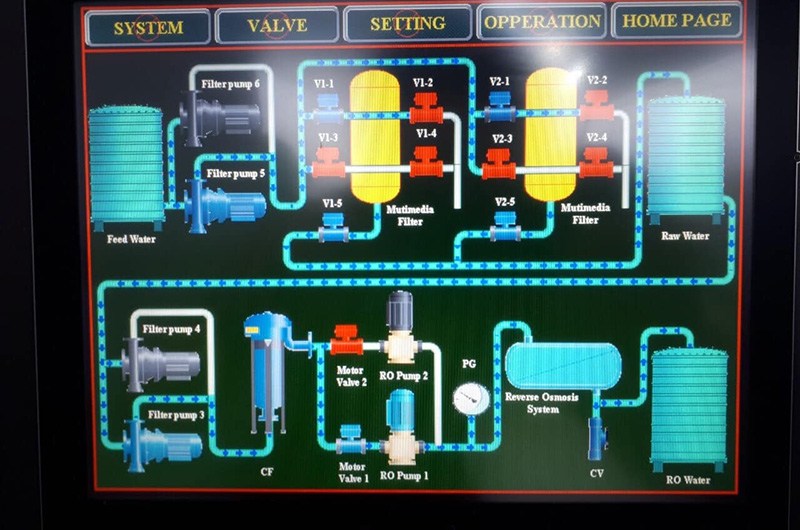

| Customer need | Looking for a partner to provide control solutions in the country for long-term cooperation, specifically the following requirements:

|

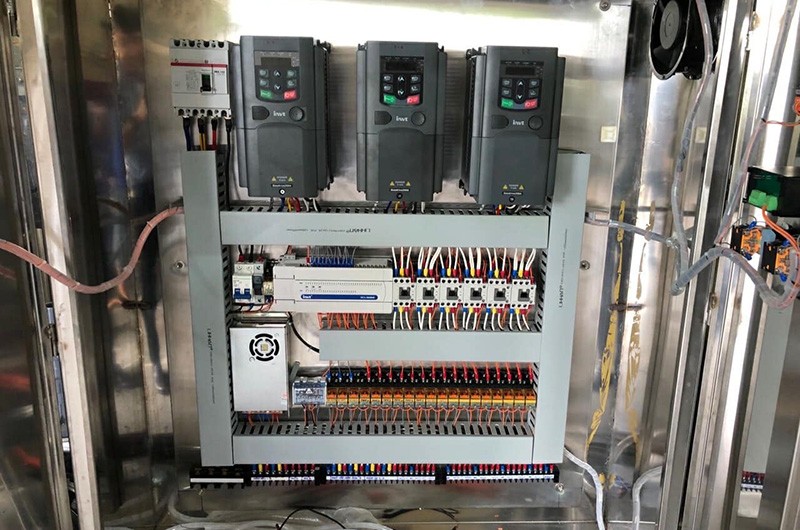

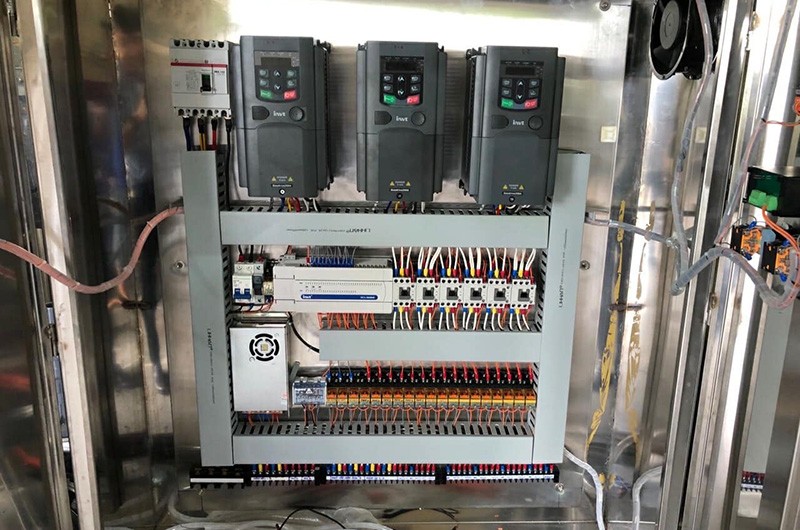

| DAT’s solutions |

|

| Application results |

|

Other applications:

Successful installation of the medium-voltage GD5000 VFD has led the business to make a second investment, recognizing the high efficiency it offers

View more

DAT Group collaborates in manufacturing a flying cutting system that meets export standards

View more

Application of GD5000 medium-voltage VFD to control oxygen blowing fan in Tuyen Quang steel plant

View more