Dinh Nen Paper Company trusts DAT’s comprehensive automation solution

After years of using products and experiencing services from DAT ecosystem, Dinh Nen Co., Ltd. has decided to continue placing complete trust in DAT for technology enhancement across their entire paper mill system. Upon completion, DAT’s comprehensive automation solution has helped Dinh Nen increase efficiency and reduce dependence on labor, ensuring smooth production operations amidst the social distancing measures caused by the Covid-19 pandemic.

Project information

| Customer need | Customer’s Issue | Solutions | Application results |

| Paper Mill System |

|

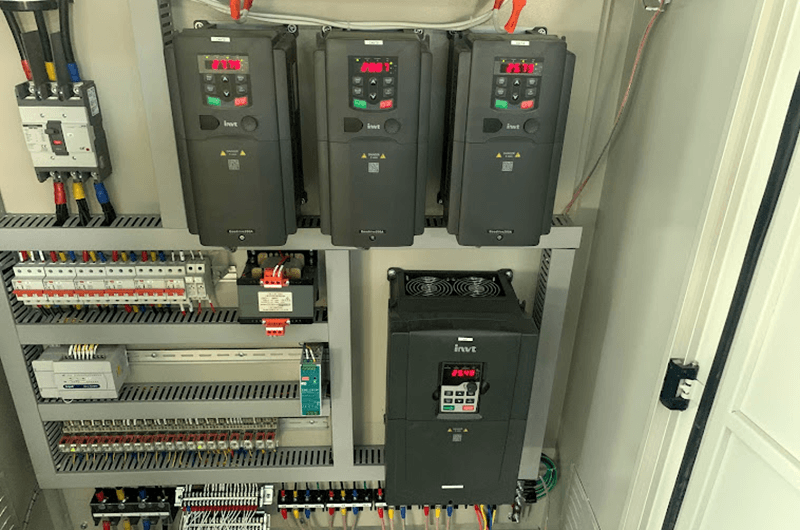

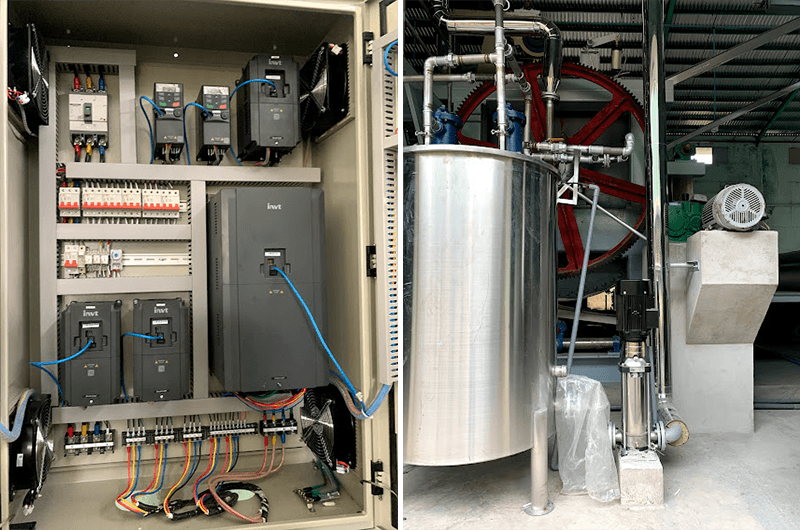

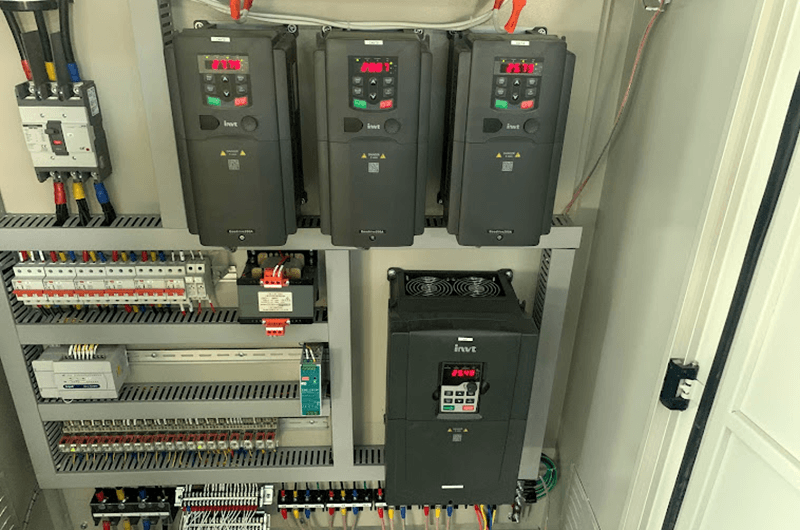

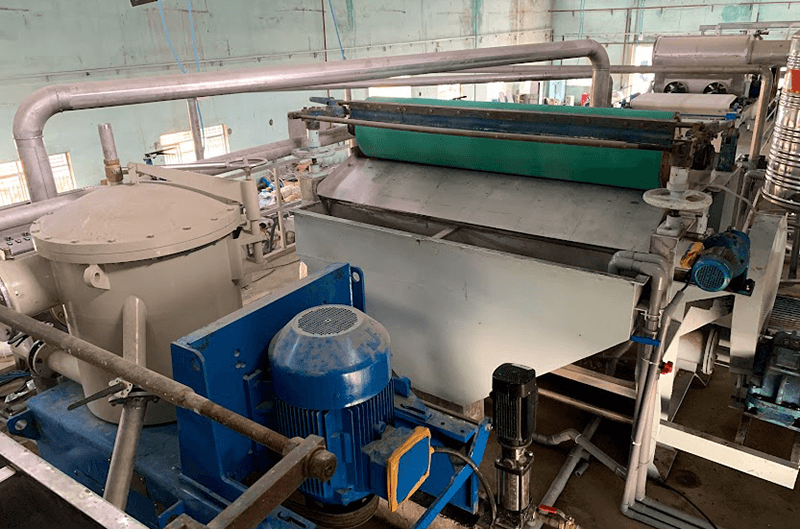

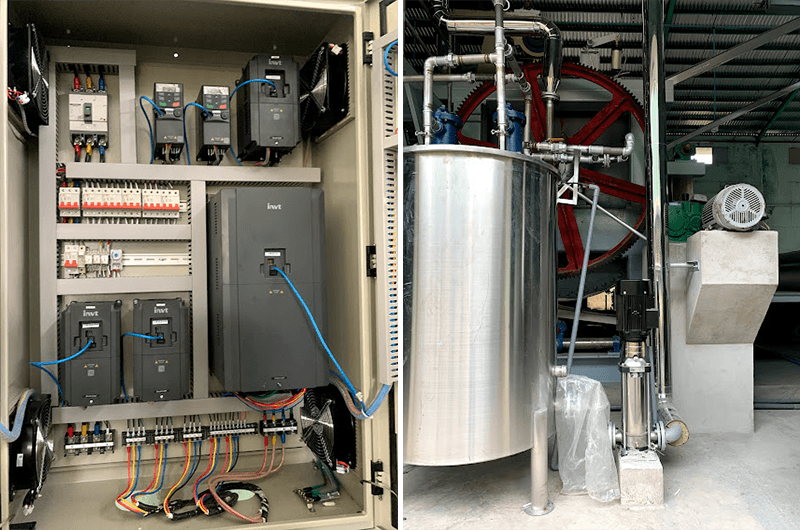

High-speed synchronized control cabinet for paper mill system

Configuration includes various INVT devices:

|

|

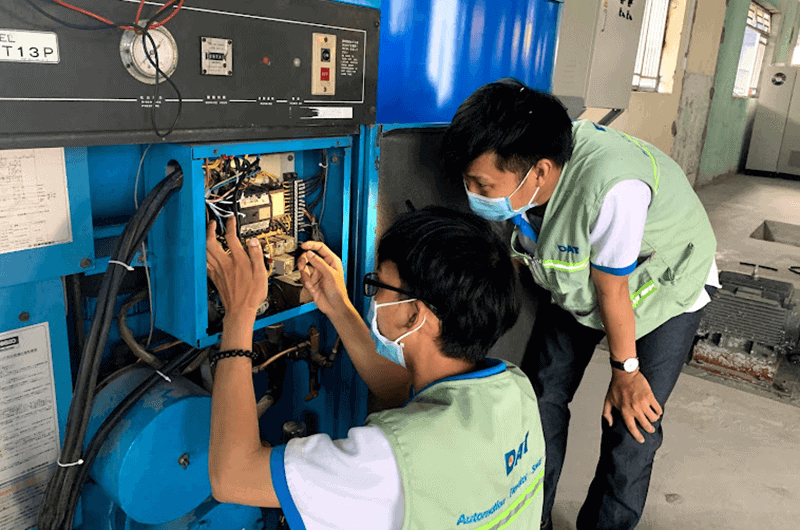

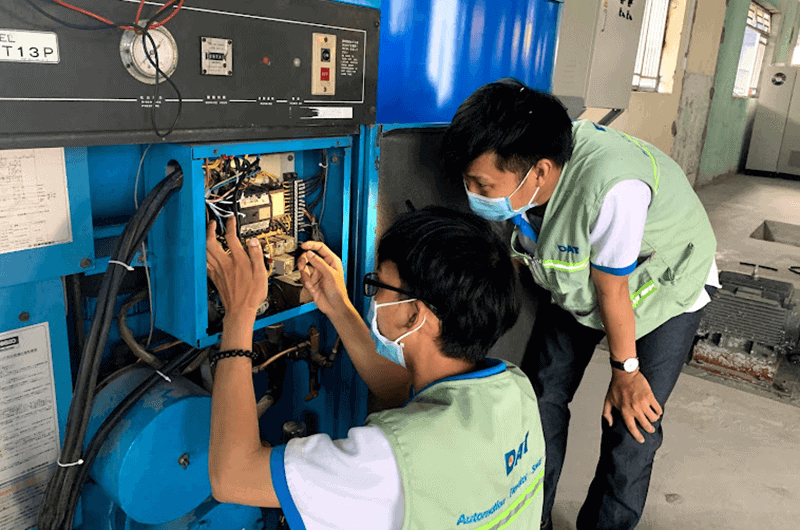

| Air Compression System (33kW) | Air compressor lacks VFD integration, resulting in excess energy consumption and unstable pressure | Installing a variable frequency drive combined with a pressure sensor.

|

|

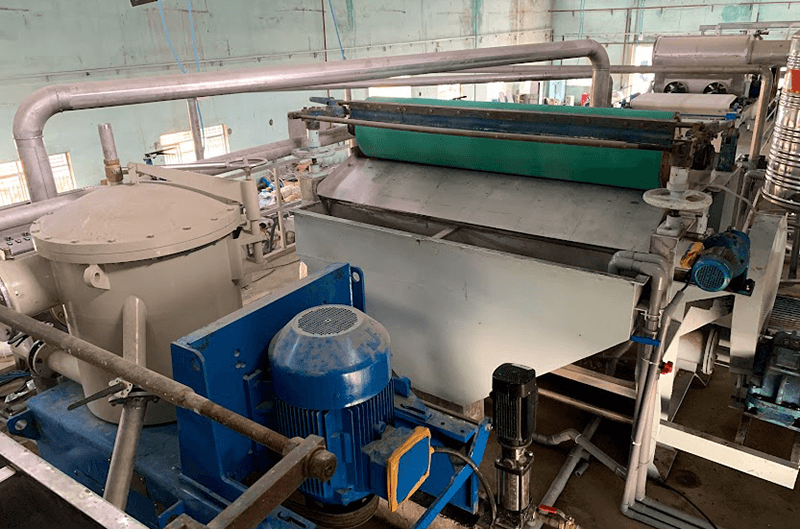

| Hydraulic Grinding System (110kW) |

|

Installation of a hydraulic grinding electrical cabinet, replacing the star-delta control system.

|

|

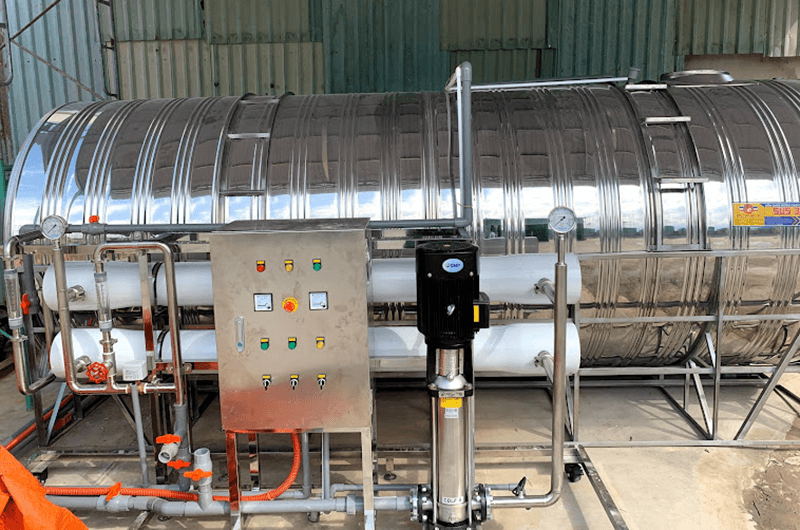

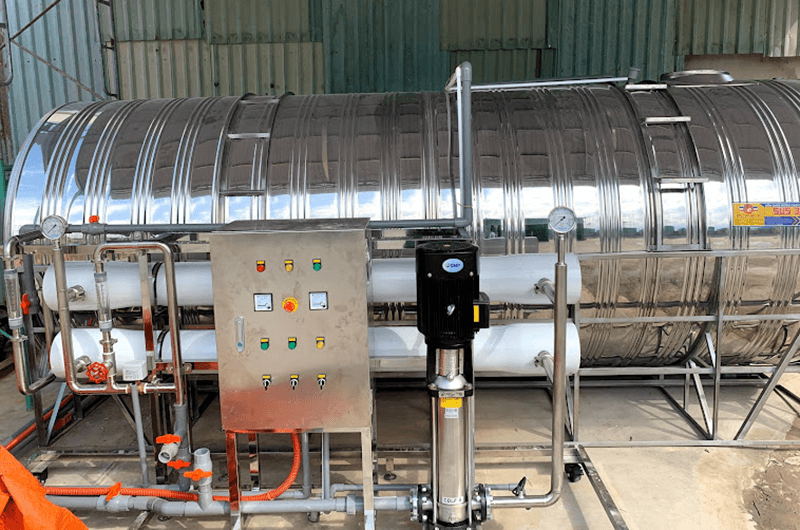

| High-Pressure Floor Pump System (55kW) |

|

System is designed with two components: the hydraulic cabinet and the control cabinet.

|

|

|

|

Installation of an electrical cabinet for agitation, pressure, vacuum, and powder pumps, replacing star-delta control system.

|

|

Previously, the use of paper mill system faced numerous difficulties due to the predominant reliance on imported components, and when issues arose, there was a lack of timely guidance and knowledge transfer from suppliers. Currently, these challenges have been exacerbated by the complex evolution of the Covid-19 pandemic worldwide, leading to continuous delays in transportation and trade activities.

In this context, Dinh Nen Co., Ltd. quickly sought assistance from DAT to construct a high-performance paper mill system, reducing dependence on labor and foreign suppliers.

With over 17 years of experience in the field of automation, especially in the paper industry, DAT promptly addressed all needs, helping Dinh Nen overcome challenges and maintain smooth operations during this period. Additionally, DAT is always ready to address any issues arising from the machinery system 24/7.

Up to the present, DAT ecosystem has earned trust and positive evaluations from over 10,000 customers nationwide. The combination of high-quality products, exceptional features, specialized automation solutions, and dedicated services from DAT continues to enhance efficiency, save production costs, reduce product prices, and elevate competitiveness in the market for customers.

For any inquiries, please contact the hotline at 1800 6567 (toll-free) for prompt assistance and support.

Other applications:

Successful installation of the medium-voltage GD5000 VFD has led the business to make a second investment, recognizing the high efficiency it offers

View more

DAT Group collaborates in manufacturing a flying cutting system that meets export standards

View more

Application of GD5000 medium-voltage VFD to control oxygen blowing fan in Tuyen Quang steel plant

View more