Intelligent Specialized VFD GD270 – Cost-Optimized Solution for Pump, Fan, and HVAC Applications

INVT officially introduces its new line of VFDs, GD270, with advanced features tailored for pump and fan applications. With a wide power range, compatibility with various motor types, diverse protection levels, and easy operation, GD270 offers a cost-effective solution for systems such as aquaculture, wastewater treatment, dyeing, and HVAC.

INTELLIGENT AND HIGHLY EFFICIENT

Through GD270, INVT has made a significant stride in providing a new specialized VFD version that meets the modern control requirements of pump, fan, and HVAC applications, while being more cost-effective compared to similar product lines. Built upon the foundation of GD300-16 series, GD270 incorporates several intelligent technical characteristics to enhance user efficiency.

GD270 supports various motor types, including both synchronous (SM) and asynchronous (AM) motors.

In addition to dedicated programs for pump and fan applications, GD270 also features special functions such as Eco mode, Energy-saving control, Fire ride-through, Anti-waterhammer, warwe level control, and cleaning. These functions help save energy and adapt well to dusty, high-temperature, and high-humidity environments. Furthermore, its specially designed thick circuit board coating ensures GD270’s long-term durability.

GD270 integrates 2 expansion slots for various types of cards: I/O card, IOT card, and communication cards like Profibus, Profinet, Ethernet, and CANopen. This enhances the connectivity, control, and remote monitoring capabilities of the device.

HIGHLIGHTED FEATURES OF GD270

In addition to modern communication protocols, flexibility, availability, and low investment cost, GD270 provides high efficiency to businesses through specialized features for pump and fan applications, as well as simplifying production and operation processes.

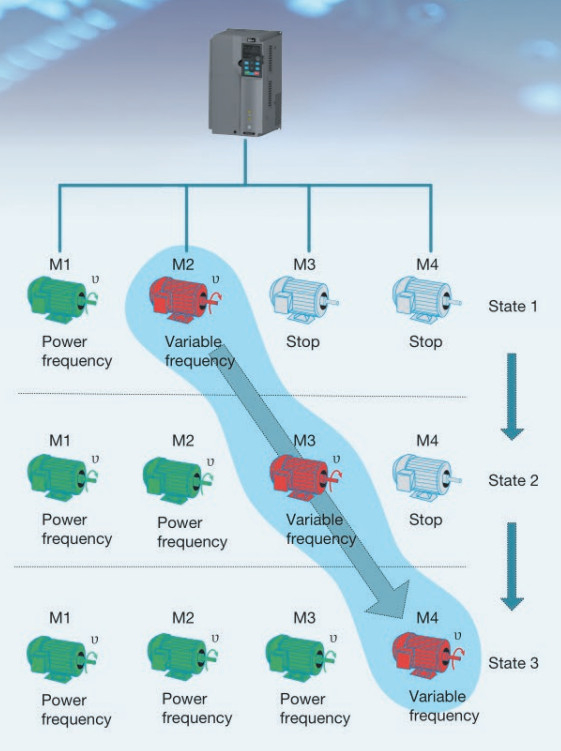

Intelligent Multi-Pump Control Mode

GD270 VFD receives pressure sensor signals (mounted on the main pipeline), automatically adjusting the frequency and thus changing the pump speed. When high water demand is needed, VFD increases the pump motor speed to maintain pressure. Conversely, when water demand is low, VFD reduces the pump motor speed or stops it completely. This ensures stable system operation and extends the motor’s lifespan.

GD270 VFD controls voltage regulation, rotation alternation, and soft starting when adding or removing pumps. It can control up to 2 pumps (or up to 4 pumps with an I/O module card) and features integrated PID control. The VFD supports primary pump and auxiliary pump control, supporting up to 8 pumps with an I/O card, balancing pump operation times, real-time monitoring, and control.

Condensation Protection Mode

Moist and cold environments can cause condensation, which may lead to motor damage. By creating a DC current to keep the motor warm, GD270 VFD helps users avoid this issue.

Pump Head Cleaning Mode

GD270 VFD has the ability to self-clean pump impellers before operation. It performs a periodic pump cleaning mode by rotating in forward and reverse directions, as well as resting, in order to reduce pipe clogging and maintenance costs.

Fire-Ride-Through Mode

GD270 VFD endeavors to operate the motor as long as possible (ignoring OFF signals), regardless of the abnormal surrounding conditions, to enhance air circulation and survival time in critical situations.

With its remarkable advantages, GD270 is an indispensable choice for businesses seeking high-performance and cost-saving solutions for pump, fan, and HVAC applications. Always at the forefront of product diversification, DAT now offers the intelligent specialized VFD GD270, immediately fulfilling the needs of customers in Vietnam with its superior warranty, maintenance, and service policies. For any inquiries about the product or solutions, customers and partners are encouraged to contact DAT through the toll-free hotline 1800 6567 for prompt assistance.