SIEMENS equipment successfully applied to the Flying Cut-Off System

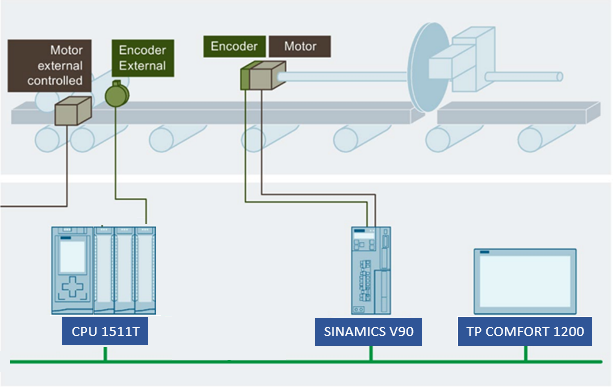

Based on its successful deployment experience in various drive control applications, DAT promptly responded to the optimization requirements of Viet Steel Company’s Flying Cut-Off System. DAT’s utilization of prominent Siemens equipment: PLC S7-1500T, HMI TP Comfort, and Servo V90 PN for the flying cut-off application has brought superior solutions in durability, high precision, and professional operational interface for Viet Steel.

Project Information

| Customer Name | VIET STEEL MACHINE CO., LTD. |

| Industry | Machinery Manufacturing |

| Customer Needs | Optimization of the Flying Cut-Off System using Siemens equipment |

| DAT Solution | Using PLC S7-1500T, HMI TP Comfort, Servo V90 PN |

| Application Results |

|

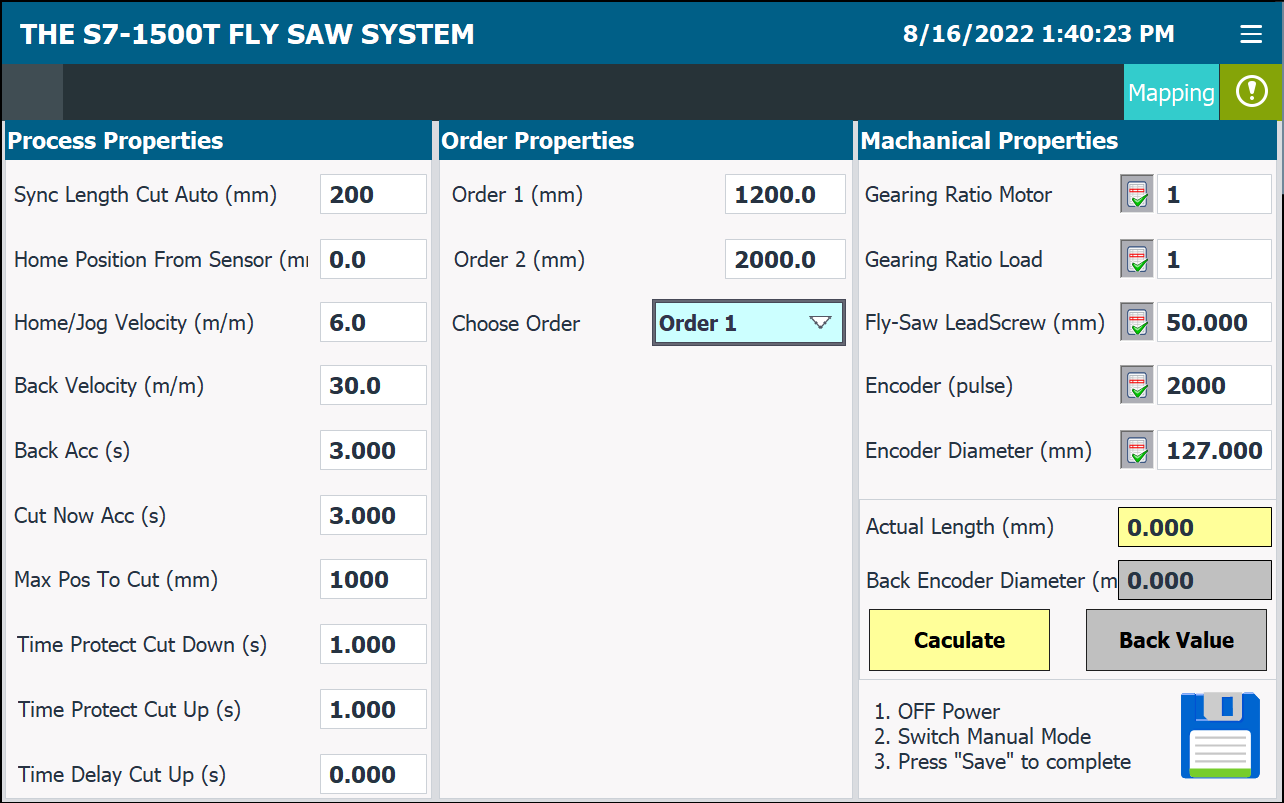

- Servo SINAMICS V90 PN: The 7kW Servo Motor strongly meets the load of the cutting table mechanism, with its dynamic turning ensuring smooth and stable operation.

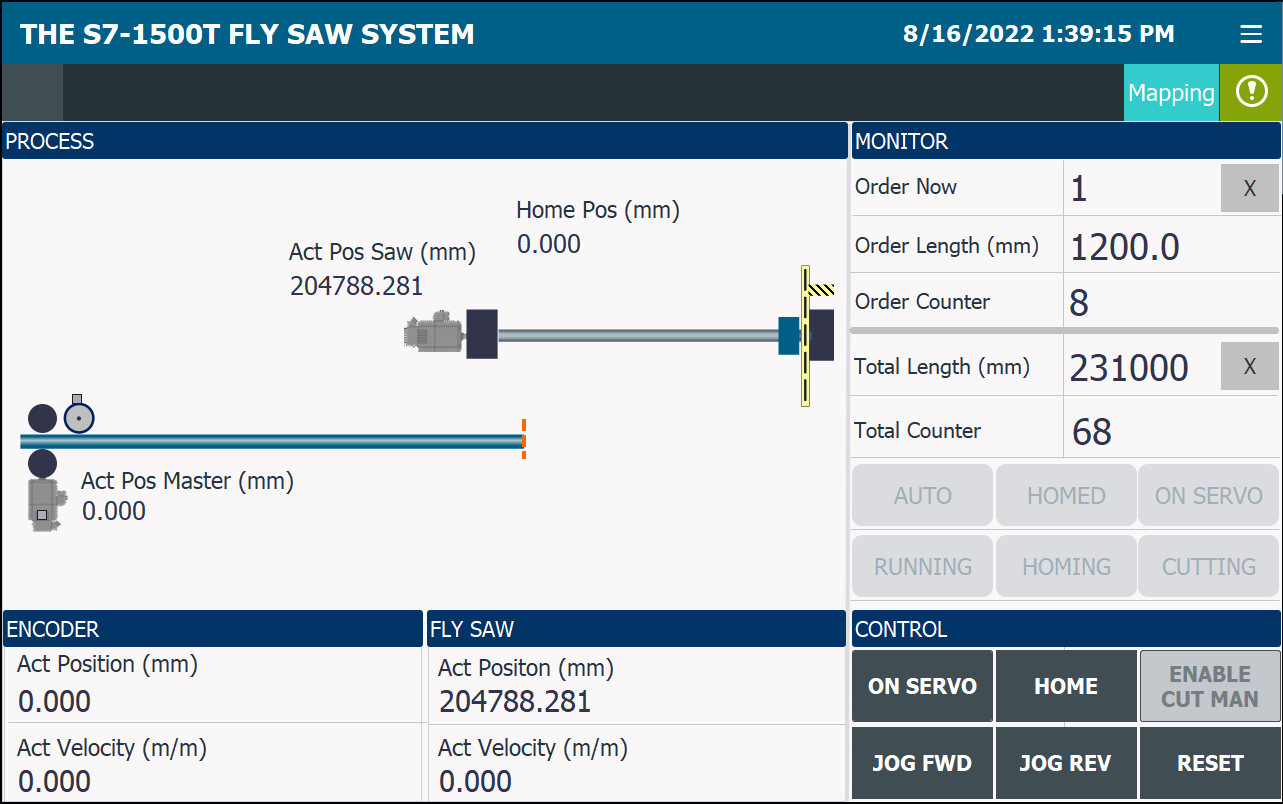

- HMI TP COMFORT 1200: The high-performance HMI screen with VBScript support provides a vivid, intuitive interface and a seamless user experience.

The system includes both manual and automatic operation modes:

- Manual operation mode: Operators can move the flying cut-off axis and perform cutting in a static state, or synchronize cutting while the material is in motion.

- Automatic mode: Unlike flying cut-off systems using CAM synchronization, this system applies Siemens’ GearInPos function. After cutting, the system automatically returns to the Home position without needing to complete the CAM cycle. This allows the system to cut shorter lengths efficiently.

- GAP feature: The system has a fast movement function to separate the cut product or can move slowly backward compared to the material after cutting.

- Efficiency: The system is easy to configure, operates smoothly, and achieves very low cutting inaccuracies.

At present, DAT has completed the construction of a specialized demo set for the Motion CPU 1500T function to serve research and development tasks for advanced systems, aiming to better meet the diverse needs of customers. In addition to the flying cut-off solution, DAT’s engineering team can also customize programs for similar applications such as rotary cutters, multi-axis synchronous motion systems…and fine-tune orders according to each customer’s specific requirements. Furthermore, the rapid troubleshooting process, flexible system replacement, and upgrade capabilities provide peace of mind for customers when partnering with DAT.

For any inquiries or support regarding products and solutions, customers are encouraged to contact the toll-free hotline at 1800 6567.