Premium Super VFD Meeting the 4.0 Platform

Recognizing that the global industrial sector is undergoing its most significant changes in over 100 years, smart manufacturing is an inevitable trend with the involvement of Robots, Internet of Things (IoT), Artificial Intelligence (AI), Big Data (BD), and Cloud Computing.

Race to Lead Industry 4.0

History of the previous three industrial revolutions shows a common thread: each revolution was marked by a groundbreaking invention in the field of science and technology. The first industrial revolution in the late 18th to early 19th century began in England with James Watt’s invention of the steam engine, transforming the economy from simple, small-scale labor-based systems to large-scale industrial machine-based economies. The second revolution, occurring later, introduced electric motors, electronic innovations, and the electrification era, driving the development of various industries such as metallurgy, machinery manufacturing, shipbuilding, military industry, transportation, and chemical industry. The third industrial revolution, following World War II, brought about automated production based on computers, electronic devices, and the Internet, creating a connected world with advanced technological products and new operational methods.

As a natural progression, the Industry 4.0 revolution we are currently experiencing is driven by remarkable technological advancements. The concept of “Industry 4.0” originated from the German government’s strategy for high-tech, computerized manufacturing. Its characteristic is the creation of smart factories through optimized process automation, modular structures, and real-virtual monitoring systems. This is called the digital revolution, utilizing technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), Virtual Reality (VR), Augmented Reality (AR), social networks, cloud computing, mobile, and big data analysis (SMAC)… to transform the entire real world into a digital one. This revolution is proving to have a powerful and credible impact on all aspects of social life.

Those who grasp technology have the power to shape the game. The profound penetration of this revolution begins in the industrial sector. As a result, major manufacturing and technology corporations around the world are increasingly applying the advancements of the 4.0 revolution, participating in the race to lead, and dominating technological advantages in the manufacturing field. A plethora of smart technology products and industrial machinery are being developed, along with entirely different operational connectivity methods, offering unprecedented operational efficiency for the modern industrial landscape.

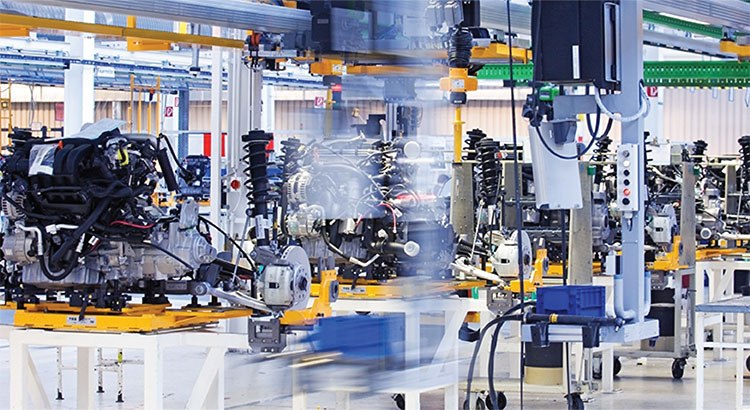

Applying digital technology to control and supervise processes automatically is the foundation of Industry 4.0 manufacturing

For manufacturing plants, achieving the transition to Industry 4.0 involves a step-by-step transformation, and changing control technology is critically important. The old control methods, which were localized, discrete, and mechanically simple, are no longer suitable for the new mode of production. The digital era of industry requires operations to be controlled by complex algorithms, a diverse array of machinery, and synchronized networks of connected devices using Supervisory Control and Data Acquisition (SCADA) systems, real-time monitoring through the internet, and data collection from devices for timely alerts. This not only helps businesses save maintenance costs and increase efficiency at lower expenses but also conserves energy, protects the environment, and fosters sustainable development.

As a globally renowned and respected technology provider in the control field, specializing in variable frequency drives, automation equipment, and electrical energy, INVT understands the current essential trend and practical needs of manufacturing enterprises. INVT constantly researches and develops advanced product lines that meet the demands of Industry 4.0. A high-end VFD supporting the digital platform, enabling direct access to Industry 4.0, was introduced by INVT in 2019 – GD350 Super VFD.

GD350 Super VFD integrates cloud computing and IoT technology, supporting optional Bluetooth/WiFi cards for wireless communication. Alongside the WiFi card, users can monitor and operate the system in real-time via the IoT system. This means that GD350 supports users in configuring and adjusting machine operating parameters through Bluetooth and the internet, using applications on mobile devices or computers, eliminating the need for traditional keyboards. Additionally, the application assists users in diagnosing faults, sending alerts, and automatically monitoring equipment operations. A notable feature of the INVT GD350 VFD is its limitless expansion capability with various types of expansion cards: PLC card (128kB), I/O card, communication card (with various communication standards), PG card, etc. The ability to control different types of motors is another outstanding feature, from asynchronous motors and asynchronous servo motors (ASM) to synchronous motors and various types of directly driven motors, spindle motors, and frequency conversion motors, all with high efficiency.

The combination of flexibility, high performance, intelligent automatic factory operation features, and a variety of modern communication protocols in GD350 enables enterprises to be prepared for Industry 4.0, achieving high efficiency while simplifying production and operation. This product is supplied to the Vietnamese market by DAT.

For inquiries about products and solutions, customers and partners are invited to contact DAT through the toll-free HOTLINE 1800 6567 for prompt assistance.

+ Over 17 years of experience in developing automation solutions

+ More than 400 talented and experienced engineers

+ Professional 24/7 service before and after sales nationwide

+ Large inventory with a wide range of VFD capacities from 0.75 kW to 500 kW

+ Over 600,000 products sold

+ Over 10,000 customers nationwide