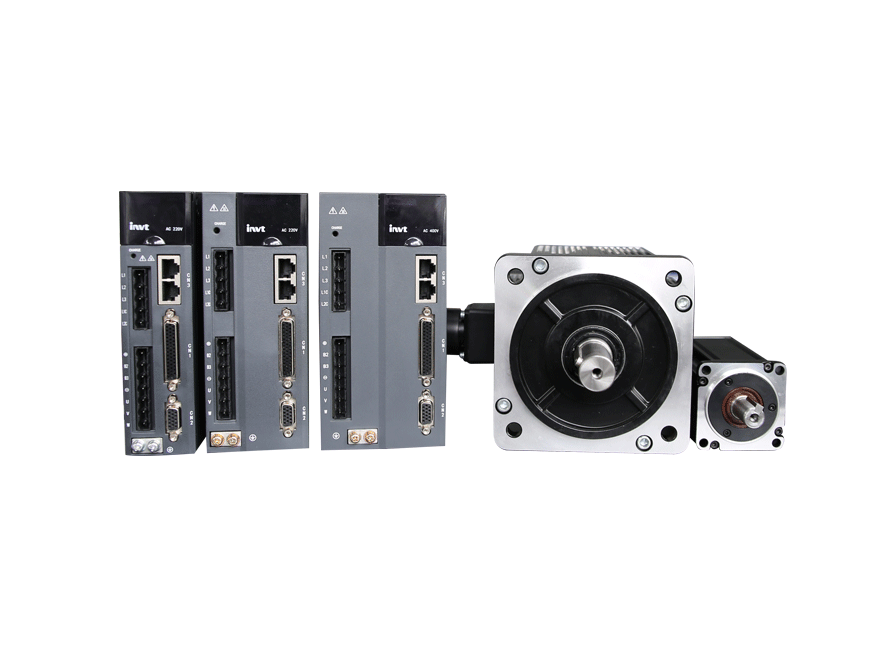

GD35-07 – Drives special for tension control

As a high-performance close loop vector drive, Goodrive35-07 drive special for tension control uses the tension control module in the algorithm, realizing the tension control in the process of wrapping up/off.

For fastest support. Please Call 1800 6567 (Free)

- Free delivery within Ha Noi, Ho Chi Minh, Can Tho

- Free installation

| Brand: INVT | Warranty: 24 months |

| Function description | Specification | |

| Capacity range | 1.5 ~630KW | |

| Input | Input voltage (V) | + AC 3Pha 220V (-15%) ~ 240V (+10%) + AC 3Pha 380V (-15%) ~ 440V(+10%) + AC 3Pha 520V (-15%) ~ 690V (+10%) |

| Input frequency (Hz) | 47~63Hz | |

| Output | Output voltage (V) | 0~ rated input voltage |

| Output frequency (Hz) | 0~400Hz | |

| Motor | Asynchronous motor, synchronous motor | |

|

Đặc tính điều khiển

|

Starting torque | 0 kHz /200% |

| Controll mode | Closed loop control. | |

| Speed ratio | 1:100 (SVC). | |

| Overload capacity | 150% of rated current: 60s; 180% of rated current: 10s; 200% of rated current: 1s; |

|

| Speed control precision | ±0.02% of maximum speed (SVC). | |

| Frequency setup mode | Digital, analog, pulse frequency, multi-step speed operation, simple PLC, PID, MODBUS communication, PROFIBUS communicaiton, can realize switching between the set combination and the set channel | |

| Torque compensation | 5% | |

| Speed detection function | Smooth start on running engine | |

| Filter | C2, C3. | |

| Communication | Modbus RTU, Profibus, Ethernet và truyền thông CAN. | |

|

I/O

|

Digital input | 8 digital inputs that accept ON – OFF value. Max frequency 1KHz, resistor 3.3KΩ with maximum frequency 50KHz. |

| Analog input | 02 Ports: + AI1, AI2 can receive input signal (0 ~ 10V or 0 ~ 20mA) + AI3 can receive input signal (-10V ~ 10V). |

|

| Analog output | Provide 02 terminals: AO1, AO2 has 0 / ~ 20 mA or 0 ~ 10 V signal, optional |

|

| Relay output | There are 2 inputs + RO1A-NO, RO1B-NC, RO1C-common. + RO2A-NO, RO2B-NC, RO2C-common. |

|

| Open collector output | HDO port: ON – OFF output or high frequency pulse output. + Y port: open collector output. |

|

| Protection function | Protection against incidents such as over current, high voltage, under voltage, overheating, phase loss, phase out, output line breakage, overload etc. | |

|

Special functions

|

Self-voltage stabilization function (AVR) | Automatically stabilizes the output voltage when the supply voltage fluctuates abnormally. |

| E-stop function | E-stop emergency stop function protects the engine | |

| Function works during temporary power failure | Do not stop working during temporary power failure. | |

| Function of inspection and supervision | Connect a computer to monitor the operation as well as set parameters for the inverter thanks to software INVT studio V1.0, HCM. | |

| Specialized specifications for tension control | Tension control mode: when user select mode 0 – vector control without PG card (used simultaneously for synchronous motor and asynchronous motor), mode 1- vector control without PG card (simultaneous use of synchronous motors, mode 2 (SVPWM control, mode 3 (closed loop vector control for synchronous motors and induction motors).) Tension feedback speed control mode : In this mode, the rotation speed is controlled to perform tension fixation First, calculate the co-velocity frequency according to the long speed of the sheet material (or fiber) and the roll diameter. Its signal the tension of the measured tension and the preset tension put on the closed-loop control PID, and finally ordered adjust the frequency of the inverter. How to calculate the frequency at the same speed as follows: f = ( V * N * i) / (π * D) Where: f: Output frequency of inverter V: material length N: number of poles of motor I: mechanical transmission ratio D: Coils diameter Speed of material obtained from module speed, into the winding diameter is obtained by the value calculated from the module diameter of the plot. To ensure the synchronous frequency accuracy can reduce PID tuning, in order to increase the system stability. In other words, accuracy of long velocity measurement is important. Tension non-feedback speed control mode: this mode of GD35-07 is applied in the case of GD35-07 as a Master and the tension feedback signal is not required, the winding diameter is calculate. The speed in this case is constant. Torque control mode without tension feedback: (open-loop tension control) tension control is controlled via direct motor torque. The speed changes according to the material’s linear speed automatically. The inverter’s output torque is calculated by setting tension and winding diameter T = (F * D) / (2 * i) Where: T: torque set for inverter F: set tension D: line coil glass I: Gear ratio of the inverter mechanical can achieve stable tension control effect in the load control mode. Note that if the torque mode is used to control the tension, the moment of inertia should be considered during acceleration / deceleration. |

|

10.000+

Customers Nationwide

15+

Year Of Experiences

3000+

Warehouse Area Above 3000 m² Is Always Available Items That Help Customers Fast Project Progress

24h

24 Hours To Complete All Processes, Procedure Is Quick And Flexible

- Control functions: Position running, synchronous running, tension control, multi-level speed, timing mode, PID …

- Integrated long-speed stabilizer and feedback tension stabilizer.

- Many functions automatically calculate the change diameter of the coil / discharge batch

- Self compensation for the moment of inertia and friction of the coil / discharge batch.

- Precise control of tension force and material speed.

- Self-detection and treatment when material is out or broken.

- Powerful communication with Modbus RTU, Pro fi bus, Can bus, Ethernet.

- Dedicated function tension control for the fiber industry , printing industry, paper industry …

Main technical properties

- V / F control, Sensorless Vector (SVC), Closed Loop Vector Control, and Torque Control

- Use for induction motor, synchronous motor and PM motor

- Torque starts at 0.0Hz: 200%

- Speed control accuracy to ± 0.02%, quick response <10 ms.

- Number of I / O ports: 19

- Communication: Modbus, Profibus DP

- Built-in IEC 61800-3 C3 and C2 Filter, Braking Unit for inverters below 30 kW,

- 36 functions to protect the inverter and motor against problems such as over current, high voltage, low voltage, overheating, phase loss, phase difference, output line breakage, overload etc.

- Compact, sturdy structure. Has its own wind-cooled road, withstands dust and moisture environment

- CE conforms to European market standards

- Electromagnetic compatibility: EN 61800-3: 2004, 2006/95 / EC

- Safety: EN 61800-5-1: 2007, 2004/108 / EC