Synchronous control solution and enhanced durability for the flying cutter system

The breakthrough solution of Servo SV-DA200 Ecam – Flying Shear synchronous control of flying cutters helps the flying cutter system achieve high accuracy, maximize operational productivity and completely eliminate waste.

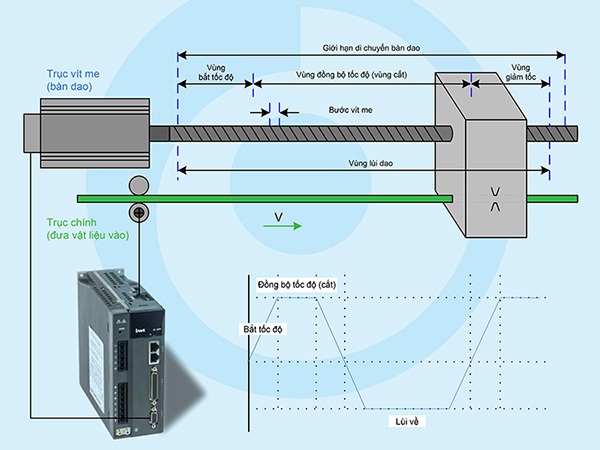

Fly cutting (also known as chase cutting) is a commonly used application in industrial production to cut materials continuously with a predetermined length according to the product’s exit speed without having to stop the line.

At present, many manufacturing and mechanical engineering factories still use static cutting mechanisms (determine the full length and stop cutting) or flying cutters but use old technology (for example, the drive system uses DC motor, inverter for flying cutter).

CUSTOMERS’ DIFFICULTIES

- The product after cutting has a large error, causing material loss and many waste products

- Low speed, low productivity

- Difficult control, complicated electrical cabinets and fast mechanical wear of cutters

Expensive repair and maintenance.

SOLUTION ANALYSIS

The system uses a DA200 Servo including a driver with integrated control features ECAM and servo motor. The servo motor is mounted on the lead screw to control the table speed and cutting speed. When the system works, the servo controller receives feedback about the length and speed of the product from the Master Encoder on the main shaft and the signal about the distance and speed of the tool from the Slave Encoder, then calculates it to control the motor to help the table move synchronously to ensure the required machine technology and to cut precisely according to the installed position and length. When the material speed and cutting length change, the system immediately responds to the Servo controller to quickly adjust the motor speed to precisely control the position and maintain a stable speed, ensuring accuracy even at high cutting speeds.

SOLUTION ADVANTAGES

- System synchronization, extremely flexible and precise position control help the cutter achieve high efficiency and speed.

- Smart, flexible operation system easily adjusts many different cutting modes, convenient for changing orders.

- Maximize cutting productivity by improving system speed, reducing machine downtime to a minimum. In addition, the system has a line cutting feature to help improve cutting errors and eliminate waste.

- Reduce costs and time of maintenance and repair, advanced control algorithms for quiet machine operation, help protect the mechanical transmission system, eliminate vibration, shock, mechanical wear and tear, smooth cutters.

Take a look at DAT's specialized solution design process.

Contact an expert

If you need advice and learn about DAT’s solutions, please contact 1800 6567 to meet with experts today.

Products for solutions

Solution relate:

10.000+

15+

3000+

24h

Let's go with DAT

24/7 SUPPORT

Hotline 1800 6567