Introducing the Control System Structure of GEAT EC3000 Series Elevators

Choosing an elevator control system from a reputable supplier is a critical factor in building a strong brand, optimizing business operations, and increasing profits for elevator manufacturers and manufacturers. This article will delve into introducing the structure and prominent features of the EC3000 series elevator control system from the GEAT (Italy) brand – a solution for new elevators and cost-saving options for upgrading and renovating existing elevators, which are currently being favored by many projects.

1. The Role of Elevator Control Systems

Elevator control systems play a crucial role in monitoring and controlling the operation of elevators, determining the entire travel journey as well as the quality of that journey.

Through precisely programmed algorithms, elevator control systems enable devices to operate automatically 24/7, ensuring error-free operations such as opening and closing doors, stopping the elevator, moving it up or down, etc.

With an intelligent control system, elevators move smoothly and quietly, providing a better user experience. The control system can also provide information about the elevator’s status through user interfaces, such as display screens in the cabin or audio notifications.

Moreover, elevator control systems play a vital role in ensuring operational safety, while also monitoring performance indicators and providing data for maintenance work to keep the elevator running smoothly, minimizing potential incidents.

2. Why is the GEAT EC3000 series elevator control system trusted?

With smart controllers and special features, the GEAT EC3000 series elevator control system perfectly meets the requirements for modern, safe, convenient, and elegant control. Designed according to European standards, the GEAT EC3000 series combines logic control techniques, high-end signal processing units, and CAN bus communication technology to enhance safety and flexibility, ensuring stable elevator operation under all conditions.

3. Structure of the GEAT EC3000 Series Elevator Control System

The structure of the GEAT EC3000 series elevator control system includes: main control cabinet, cartop control cabinet, circuit board system, and accessories. Below, we will delve into each component in detail.

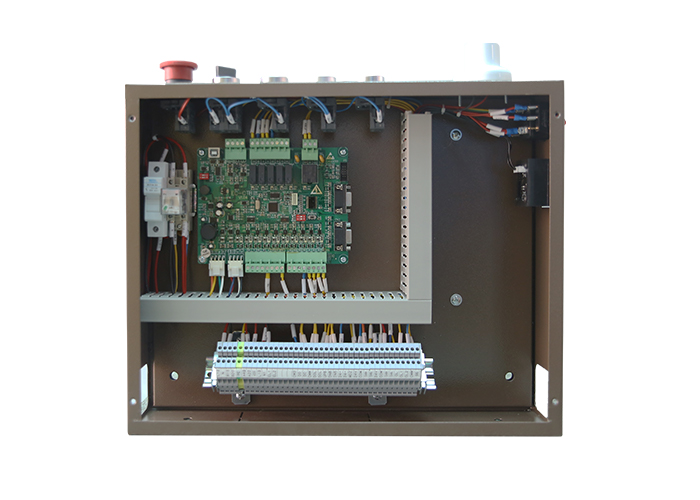

3.1 Main Control Cabinet

Featuring S-curve control algorithms, the EC3000 series control cabinets: EC3000A, EC3000E, and EC3000MRL enable smooth elevator operation thanks to flexible start-acceleration-deceleration-stop capabilities, ensuring extremely smooth operation while maintaining high operating speeds.

Among these, the EC3000A is the standard cabinet with all auxiliary features such as 2 brake power supplies, socket plug-ins:

- Absolute safety complying with EN81-1 + A3 standard, EN 61800-5-1:2007, CE marking in accordance with European market standards 2006/95/EC and 2004/108/EC. 77 different protection functions: overcurrent, overvoltage, anti-sliding, sliding…

- 18 service operation modes: peak hour mode, VIP mode, rescue mode, cabin priority…

- Smooth device cutting without noise (noise level 20dB).

- Controls up to 64 floors, maximum speed up to 6m/s.

- Supports AM and PM motor control, independent control of 2 doors without additional cost, controls double elevators and group elevators up to 8 elevators.

- Integrated emergency rescue circuit for PM traction machines, on-board PG integration, and 2 signal input ports for various encoders.

The EC3000E stands out with its compact size (20% reduction compared to standard cabinets), saving space, suitable for homelift elevators requiring strict space requirements. This cabinet line includes all protection and operation features of the EC3000 series system.

The EC3000MRL is a premium elevator control cabinet system, specially designed for cases without machine rooms, fully meeting all functions and saving space. This cabinet line is suitable for installation beside the highest floor door of the building.

3.2 Cartop Control Cabinet

The cartop control cabinet is synchronized and compatible with the EC3000 series control cabinet system, integrating the EC-CTB board to collect signals and control the cabin with outstanding features:

- CAN bus communication, MODBUS, integrated RS232.

- Load signal processing (Analog or Digital).

- Integrated cabin arrival bell, energy-saving lighting control mode, and fan control.

- Integrated simultaneous independent control of 2 cabin doors.

- Connection to notification devices such as voice, video, bell, photocell safety devices, overload…

3.3 Circuit Board System and Accessories

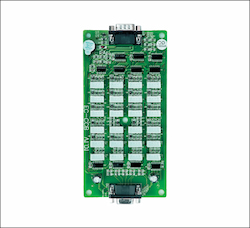

EC-CCB cabin call board:

Each elevator requires at least 1 EC-CCB board, the first board is used for a maximum of 16 floors, and an additional board is installed for the next 20 floors. Communication drivers, timed door hold mode, VIP priority mode, management, separate from the group of elevators, and independent operation.

The floor call display boards include:

- Ultra-thin horizontal matrix LED DC-03HS.

- Ultra-thin vertical matrix LED DC-03BS.

- Monochrome segment LCD 4.3″ ultra-thin DC-07K.

- Color TFT LCD 4.3″ image LM21-043-T1 with transition mode, easy vertical-horizontal switch.

- Color 7″ image and sound LCD LM21-070-T2 with transition mode, customizable images, logos, sounds on request, easy vertical-horizontal switch, elevator status notification through voice, support for multiple language voices.

Expansion modules include:

- LM11 voice status notification device.

- DM-04A SMS status notification device for elevator faults.

- EC-UCM early door opening control board.

- MC-GCL group elevator control board.

- Elevator management and control system with BS10 IC Card smart card.

Details about the circuit boards and accessories of the EC3000 elevator control system series here.