How to Choose the Right VFD for Your Needs?

VFDs are widely used in electrical and automation systems. There are many different types of VFDs available on the market, ranging from basic models to specialized and high-end units from various manufacturers. Therefore, selecting and using VFD that meets your application requirements, is highly efficient, and cost-effective can be a challenging task for users.

1. Principles for Choosing VFD

To choose the right VFD for your application, it’s essential to clearly define your application needs, usage purposes, and balance your investment level. Consider the following principles:

- Select a VFD that matches the type of motor and motor power: Understand what type of motor you need to connect to VFD, whether it’s a synchronous or asynchronous motor, single-phase or three-phase, DC or AC, and its rated voltage. Ensure that VFD’s power rating is equivalent to or greater than motor’s power rating.

- Choose VFD based on your application requirements: When selecting VFD, determine the specifics of your application, including motor speed, any advanced control features needed, synchronization requirements, communication standards, and any environmental conditions such as humidity, high temperatures, dust, or explosive atmospheres. If there are no specific requirements, you can opt for versatile and commonly used VFD like the GD20 or GD200A. For specialized needs, select VFDs with the appropriate features.

- Match VFD to the actual load: Selecting VFD according to the load type is crucial. First, determine the load type—whether it’s light, heavy, or medium—and whether it operates in short or long cycles, continuously or intermittently. Based on these factors, choose an appropriate VFD.

- Choose VFD that integrates well with your existing system and is user-friendly for programming or select a supplier capable of providing programming support for your specific applications.

- Select VFD that matches the technical specifications of the existing VFD (in case of replacement with a different brand) or according to the design requirements.

- Lastly, consider financial aspects. To ensure peace of mind, choose a reputable VFD brand with a strong presence in the market, good warranty terms, stable product quality, and responsive customer service.

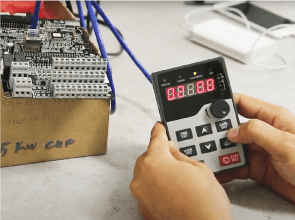

2. Considerations for VFD Use

The first thing you should do when using VFD is to carefully read the specifications provided by manufacturer for each specific product line. This will help you understand correct three-phase VFD wiring standards. To ensure everything is done correctly, it’s advisable to choose reputable companies with highly skilled engineers for installation and connection. Additionally, you should also familiarize yourself with product’s additional features, such as dust resistance, water resistance, corrosion resistance, emergency stop buttons, expandability, etc. This knowledge will enable you to install, use, and maintain equipment safely and efficiently.

All VFD manufacturers offer various product lines suitable for different applications. Therefore, it’s crucial to do thorough research before selecting and using VFD. Here are some considerations when using VFD:

- Depending on your application, choose the VFD that best suits your needs. By doing so, you can minimize costs while ensuring reliable operation.

- You need to be aware that VFDs contain sensitive electronic components that can be affected by environmental conditions. Since Vietnam has a hot and humid climate, make sure your VFD is suitable for tropical conditions.

- Ensure that the installation environment meets requirements such as temperature, humidity, location, and clearance.

- Ensure that the installation environment meets requirements such as temperature, humidity, location, and clearance. VFDs should be installed indoors, in well-ventilated cabinets with proper cooling (fans).

- Understand the VFD’s documentation thoroughly. If you don’t understand or are unsure about something, avoid making unauthorized changes to the settings.

- Seek guidance from technical experts.

- When VFD reports an error, consult the error code in the documentation to identify the cause of the error. Only restart the VFD after resolving the issue.

- Keep detailed records of any parameter changes and observed errors in the provided documentation. This information is crucial for troubleshooting by specialists in case of problems.