PLC: What is it? Structure, Operating Principles and Applications of PLC

1. PLC Overview

PLC, short for Programmable Logic Controller, is a device that allows programming to implement logical control algorithms. The PLC programming unit receives external events through inputs and executes operations through outputs. It operates by scanning the states of inputs and outputs. When there is any change in the inputs, the corresponding output will change based on the programmed logic.

The common programming language for PLCs is Ladder Logic or Step Ladder. However, each manufacturer may have its own programming languages. Popular PLC manufacturers include Siemens, Mitsubishi, Rockwell, INVT, Delta, etc.

2. Structure and Classification of PLC

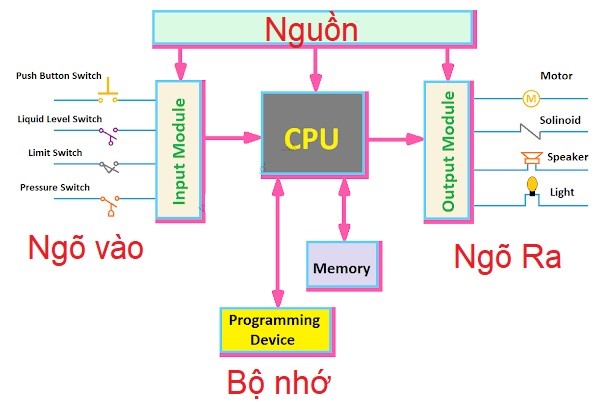

The typical PLC system comprises the following main components:

- Program Memory: RAM, ROM, and external memory like EPROM.

- Central Processing Unit (CPU).

- Input/Output Modules: I/O modules are usually integrated into the PLC, and additional modules can be added for expanding I/O.

Other components include:

- PLC-to-Computer Port: RS232, RS422, RS485 for programming and program monitoring.

- Communication Port: PLC often integrates Modbus RTU, and depending on the manufacturer, additional communication standards like Profibus, Profinet, CANopen, EtherCAT may be supported.

3. Operating Principles of PLC

The central CPU controls the entire PLC operation. The processing speed of the CPU determines the control speed of the PLC. The program is stored in RAM, and backup power in the PLC ensures the program remains intact during power issues. The CPU scans the program and executes commands sequentially.

4. Advantages and Disadvantages of PLC

Advantages:

- Excellent noise resistance, reliable in industrial environments.

- Handles complex algorithms with high precision.

- Compact, lightweight, and easy to install.

- Replaces traditional relay control circuits, meeting diverse control requirements.

- Supports industrial communication standards for Industry 4.0 connectivity.

Disadvantages:

- High cost compared to traditional relay circuits, although competition has lowered prices.

- Programming software costs vary by manufacturer.

- Users need basic PLC programming knowledge for effective operation.

5. Role of PLC in Automation Systems

In Industry 4.0, PLCs play a crucial role beyond simple logic and speed control. They facilitate communication and data exchange between control devices, creating a closed network within the production line.

6. Differences Between PLC and Other Control Systems

PLCs are gradually replacing conventional relay and contactor control systems due to their ease of modification, maintenance, and higher reliability.

| Conventional Control System | PLC Control System |

|

– Changes in the program require a full replacement. – Maintenance and repairs are challenging.

|

– Changes in inputs, outputs, and system control are easily done through software on a computer or console. – Maintenance and repairs are straightforward. – High reliability and durability. – Modular design allows for easy replacement and expansion. – Lower power consumption, faster system operation. |

7. Main Control Functions of PLC

Logic Control:

- Automated control, semi-automated process machine.

- Support for Counters and Timers

Response Control:

- PID control algorithms, Fuzzy Logic.

- Servo motor control, stepper motor control.

- Variable frequency drive control.

- Temperature, pressure, flow control.

Communication Network:

- Connecting Multiple PLC Controllers.

- Connecting PLC Controllers to the SCADA System.

8. Applications of PLC

PLC programming is applied in various industries and types of machinery, including but not limited to:

- Printers

- Packaging machines

- Textile machines

- Fiber spinning machines

- Food processing machines

- High-speed cutting machines

DAT Group Joint Stock Company is the leading product provider and solution developer in Vietnam in the fields of Industrial Automation and Sustainable Energy.

With over 17 years of development and ownership of a value ecosystem, DAT Group has earned the trust and collaboration of over 10,000 customers and partners nationwide.

DAT Group is the Authorized Representative of INVT and the Official Distributor of Siemens in Vietnam. Currently, DAT Group provides a diverse range of PLC controllers from INVT and Siemens:

- SIEMENS: LOGO, S7-1200, S7-1500, S7-300

- INVT: IVC1L, IVC3

These products are always available at DAT’s 4000m² warehouse in Ho Chi Minh City, Hanoi, and Can Tho to promptly meet customer demands. When purchasing a PLC programming unit from DAT, customers can expect quality products, specialized solutions, and outstanding services:

- Warranty for 12 months.

- Lifetime maintenance.

- 24/7 support from skilled engineers.

- Flexible payment options, delivery before procedure.

Contact the toll-free hotline 1800 6567 or chat directly with a consultant in the bottom right corner of the screen. DAT is always ready to assist!