Guide to Controlling a VFD Using HMI

The method of controlling a VFD through HMI is commonly applied in practical applications due to its numerous advantages, including multi-point connectivity, long-distance high-speed transmission, ease of implementation, and cost-effectiveness. This article will help you easily control a VFD using HMI.

1. Overview

HMI stands for Human Machine Interface, which is a device that serves as a communication interface between humans and machines. In the field of industrial manufacturing, HMI plays a crucial role in enabling operators to monitor and control machinery easily, thereby increasing work efficiency and quality.

Key advantages of HMI include:

- Touchscreen interface for user-friendly operation, similar to a smartphone.

- Program memory includes ROM, RAM, and EPROM..

- Programming software supports interface design tools, animations, functions, and control commands.

- Supports communication protocols such as Modbus, CANopen, Profinet, Profibus…

Currently, in the Vietnam market, there are many HMI manufacturers, including Siemens, Mitsubishi, Rockwell, Fuji, INVT, Delta, and more.

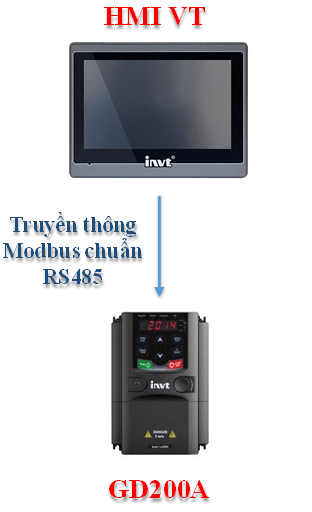

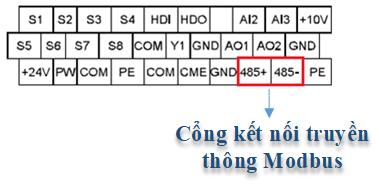

2. Communication Connection Diagram for Modbus between VFD and HMI

Connection diagram for INVT GD200A VFD and INVT VT HMI

HMI VT

VFD GD200A

3. Instructions for Setting up and Configuring Communication on HMI and VFD

3.1 VFD Configuration Parameters

| Parameter | Name | Function | Setting Value |

| P14.00 | Slave Address | Range: 1 – 127 | 1 (Default) |

| P14.01 | Baud Rate |

0: 1200BPS 1: 2400BPS 2: 4800BPS 3: 9600BPS 4: 19200BPS 5: 38400BPS 6: 57600BPS 7: 115200BPS |

4 (Default) |

| P14.02 | Frame |

0: No check (N,8,1) RTU 1: Even check (E,8,1) RTU 2: Odd check (O,8,1) RTU |

1 (Default) |

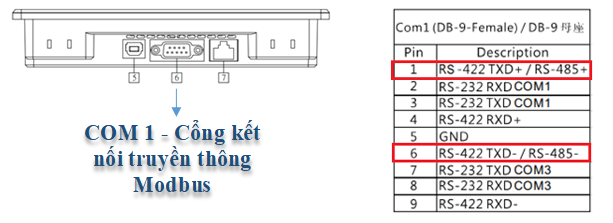

3.2 HMI Configuration

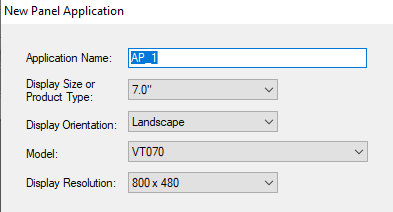

Step 01: Open the HMI VT Designer interface design software

Step 02: Select the HMI VT model

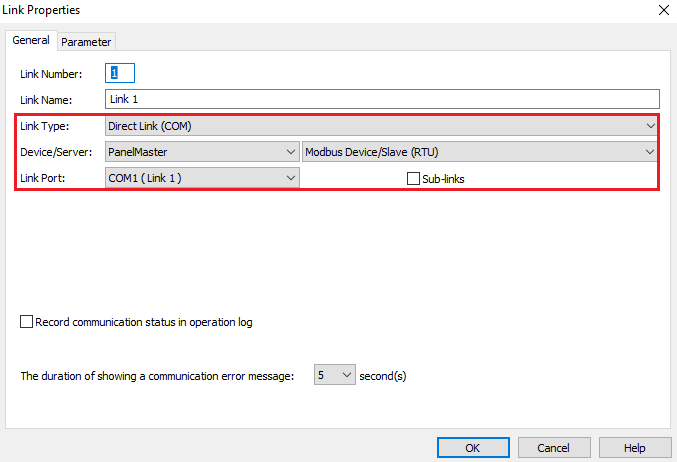

Step 03: Choose the RS485 connection type and COM 1 communication port

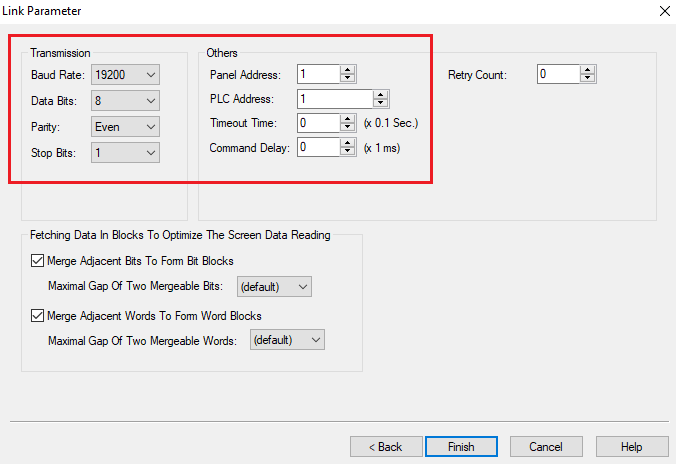

Step 04: Configure Modbus RTU communication. Note: The communication configuration between HMI and VFD must be compatible.

4. Controlling the VFD Using HMI

Modbus communication parameters for controlling the VFD’s Forward/Reverse operation and setting frequency.

| Communication Function | Communication Address | Function | Read/Write |

|

Control |

2000H |

0001H: Forward Run |

Read/Write |

| 0002H: Reverse Run | |||

| 0003H: Jog Forward | |||

| 0004H: Jog Reverse | |||

| 0005H: Stop | |||

| 0006H: Freewheel Stop | |||

| 0007H: Reset Fault | |||

| 0008H: Jog Stop | |||

|

Set Parameters |

2001H |

Set Frequency |

Read/Write |

For more detailed instructions on how to control a VFD using HMI, please contact the toll-free hotline at 18006567 for quick support.