Automation Solutions Enhancing Efficiency in the Fiber Dyeing Industry

The textile dyeing industry is one of the sectors with complex production chains and high technological requirements. However, up to 50% of machinery and equipment in the textile dyeing industry in Vietnam are technologically outdated by about 15 – 20 years compared to Thailand and China, and 25 – 50 years compared to the world. Therefore, optimizing machinery and equipment, and improving technology should be the top priority for textile dyeing enterprises today because this investment will help reduce input material losses, increase productivity, and enhance the value of goods in the export market.

Some successful solutions applied in many fiber dyeing factories include:

- Solution: Installing variable frequency drives (VFDs) to control motor speeds to improve technology, optimize performance, and save energy:

With the ability to change the frequency of current, thus altering motor speeds, VFDs are widely used in electrical and automation systems. The textile dyeing industry is no exception. By installing VFDs to control motor speeds, dyeing factories can increase productivity and save energy.

Machines that can use VFD installation solutions in the dyeing industry include:

- Yarn brushing machines

- Yarn twisting machines

- Knitting machines (circular knitting machines, flat knitting machines)

- Fabric dyeing machines (Jigger dyeing machines, JET dyeing machines)

- Centrifugal squeezing machines

- Fabric shaping machines

- Solution: Energy-saving and technological improvement for industrial boiler systems

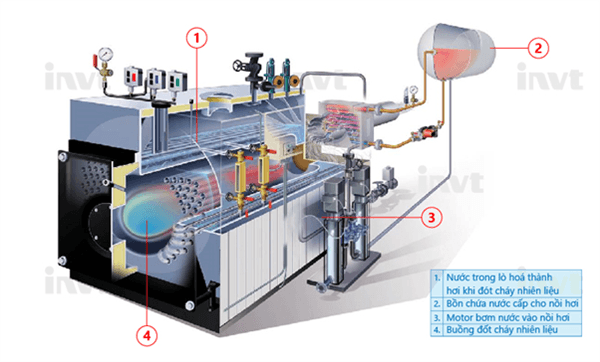

Boilers are essential equipment in textile dyeing factories, using fuels such as coal, wood, rice husks, and waste paper to boil water and generate steam for various processes in the factory.

Challenges faced by factories using the old operating method:

- Unstable steam flow and pressure.

- Unsmooth start-up, causing mechanical shock, frequent mechanical and engine checks and maintenance.

- Motors always run at full capacity, wasting electricity.

- The system requires many electrical devices such as timers, relays…

- The system generates a lot of exhaust gas and sudden increases in the concentration of harmful substances, affecting health and the environment.

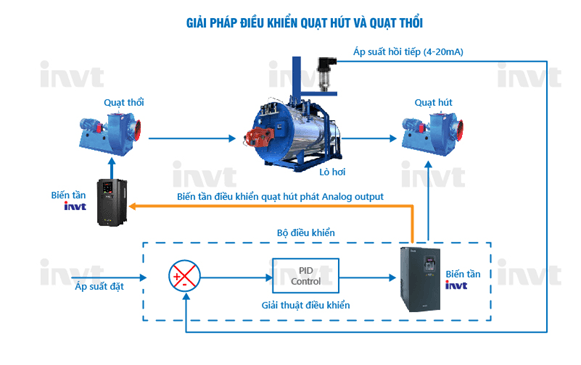

The solution is to use the INVT GD200A new-generation multi-purpose variable frequency drive to control the blower motor, exhaust fan motor, and feed conveyor motor of the boiler system to stabilize steam flow and pressure, saving electricity and increasing the motor’s service life. At the same time, upgrading the system to achieve higher production efficiency.

- Solution: Stable control and energy saving for multi-pump systems

Water pumps and multi-pump systems are widely used in fiber dyeing and water treatment areas.

The old-style pump control method uses 3-phase motors started in star-delta or direct connection to the grid. When operating, the pumps always run at full load until the tank/reservoir is full or the pumps have enough water, then the pumps are shut off.

Challenges faced by factories using the old operating method:

- Pumps have high start/stop frequency, reducing pump life.

- Pumps always operate at full power even when demand is low, wasting energy.

- Voltage drop in the electrical system due to simultaneous starting of many pumps.

- Cost and space required for building water towers (for water distribution stations).

- Unstable water pressure and flow rate affecting other systems and causing pipe breakage, valve damage…

- Some pumps work too much or too little, causing damage and corrosion to components.

- Increased operating, maintenance, and repair costs.

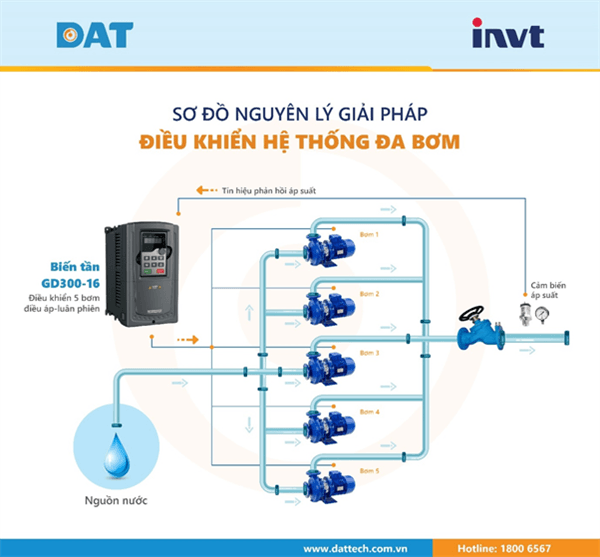

The solution is to use the INVT GD300-16 dedicated HVAC variable frequency drive to control the pressure-regulating and alternating operation of the pump system, solving all the above problems completely. INVT inverters GD300-16 integrates many smart functions, including pressure regulation, alternating and soft start-up control when adding or reducing pumps (expandable up to 11 pumps), operating time balancing (anti-rust) for pumps, monitoring and controlling water supply levels to prevent pump idling, real-time control (peak and off-peak hours) to optimize electricity savings.

DAT – 14 years in the field of automation development for the fiber dyeing industry

Established in 2006, DAT has continuously built a value ecosystem, focusing on R&D to create specialized solution systems for the Vietnamese fiber dyeing industry. Thanks to dedication and practical benefits, 7000 customers have chosen DAT to increase efficiency in production and business activities. Among them are Tuyet Tran Manufacturing – Trading Company, Dong Phuong Knitting Company, Phong Phu Company, Thanh Cong Investment – Trading Company, An Thinh Phat Design – Construction Investment Company, Kim Thanh Hung Dyeing Company…

BENEFITS FROM DAT’S SOLUTIONS:

- Technology improvement, enhancing product quality.

- Increased efficiency and machine speed, thus increasing production efficiency.

- Easy operation, waste reduction.

- Stable machine operation, engine protection, reducing machine downtime and maintenance costs.

- Energy saving.

Conclusion

Finding a reputable, capable, and dedicated automation service provider to accompany production activities helps overcome problems and provides effective technological solutions, which are very important in the production activities of dyeing industry enterprises. In addition to technological support, dyeing industry enterprises can also produce with peace of mind without worrying about any issues arising from the machinery system. Thanks to the value ecosystem, DAT confidently becomes the number one choice for dyeing industry enterprises in Vietnam. For more details, please contact the hotline 18006567 for quick support.

DAT Technology Co., Ltd. (DAT) proudly stands as a leading provider of products, solutions, and services in the Vietnamese market for variable frequency drives, automation, elevator control, and solar energy.

- With over 14 years of experience in developing automation solutions, DAT has sold 500,000 products to over 7,000 customers nationwide.

- With a team of over 350 talented and experienced engineers

- DAT ensures prompt delivery and cost-saving technical support through a large inventory of variable frequency drives up to 1000kW and a nationwide technical service network available 24/7.

- The flexible process of “Replace first, formalities later”.

- DAT is a comprehensive strategic partner with the technology conglomerate INVT, collaborating from research and testing to product and solution introduction to the market.

- By deeply understanding and mastering technology, DAT optimizes processes, solutions, and services.

- DAT provides technical training programs, technology understanding, and machinery upgrade consultancy for customers.

For more detailed information, please visit www.dattech.com.vn and call the toll-free HOTLINE 1800 6567