Enhancing Efficiency Solutions in the Plastic Industry

The plastic manufacturing industry is experiencing robust growth, with an annual growth rate ranging from 16 to 18%, presenting numerous opportunities as well as challenges for businesses in the sector. The challenge lies in how to improve technology, enhance efficiency, product quality, and optimize costs to gain a competitive edge in the market, especially in the export market, which is a complex puzzle for Vietnamese plastic enterprises.

CHALLENGES IN TERMS OF TECHNOLOGY

Fierce competition in both domestic and export markets poses significant challenges for Vietnam’s plastic industry. The competitiveness is often hampered by technological limitations such as low precision, slow machine speeds, low production efficiency, difficult operation and machine fault handling, high maintenance costs, and motor maintenance…

Therefore, finding solutions to improve technology, increase production efficiency, and save energy is a critical need for plastic industry businesses.

APPLICATION OF AUTOMATION TECHNOLOGY TO ADDRESS CHALLENGES IN THE PLASTIC INDUSTRY

Depending on the usage demand, the plastic industry is divided into various segments such as PE plastic, PP plastic, PS plastic, and PVC plastic…

To optimize efficiency, improve product quality, and save costs, the machinery systems in plastic factories need to operate efficiently and stably for long periods. The application of automation technologies aims to improve equipment and enhance operational capabilities, which many plastic factories choose to overcome current difficulties.

Some solutions that have been applied in many manufacturing plants include:

- Automation Solutions in PE Plastic Manufacturing Industry

Most machinery systems in the PE plastic manufacturing industry in Vietnam consume a lot of energy, fail to meet product quality requirements, and lack competitiveness. Applying automation with new solutions to the PE plastic production process will increase product value, reduce costs, and compete effectively in both domestic and international markets.

Some machinery equipment in PE plastic manufacturing plants that can be equipped with variable frequency drives:

- Plastic recycling machines

- Gluing machines

- Nylon bag blowing machines

- Printing machines

- Bag cutting machines

- Automation Solutions in PP Plastic Manufacturing Industry

Using inverters will help machinery equipment in PP plastic packaging manufacturing plants achieve high-speed requirements, stable operation, easy order changes, and minimize downtime.

Some machinery equipment in PP plastic manufacturing plants that can be equipped with variable frequency drives:

- Thread cutting machines

- PP bag weaving machines

- Film coating machines

- Printing machines

- Bag cutting machines

- Automation Solutions in PS and PVC Plastic Manufacturing Industry

With the traditional operating methods, PS and PVC plastic manufacturing plants face issues like pressure loss, mechanical wear, transmission ratio issues, difficult operation, and high waste. Applying variable frequency drives to machinery equipment quickly solves these limitations.

Some machinery equipment in PS and PVC plastic manufacturing plants that can be equipped with variable frequency drives:

- PVC plastic extruders

- Plastic shredders

- PS plastic blowing machines

- Plastic shaping and stamping machines

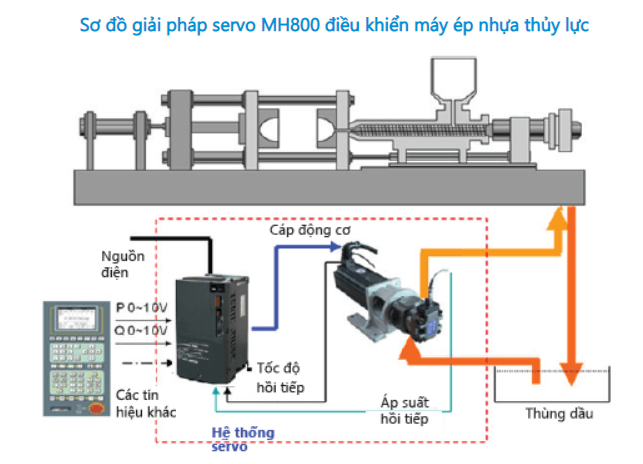

- Hydraulic Plastic Molding Machine Control Solutions

Currently, there are two types of plastic molding machines on the market: hydraulic plastic molding machines and electric motor-driven plastic molding machines. Considering popularity, hydraulic plastic molding machines are widely used due to their affordable investment costs.

- Hydraulic plastic molding machines consume a significant amount of electricity, accounting for up to 80% of the total electricity consumption of the entire plant.

- Some systems use asynchronous 3-phase motors to control oil pumps, resulting in continuous machine operation and unnecessary power wastage.

- Systems are controlled by outdated technology, leading to unstable operation, frequent failures, time and cost-consuming repairs, material wastage, reduced production efficiency, and reduced equipment lifespan.

Applying the Servo MH800 control solution for plastic molding machines helps customers save up to 80% of electricity, improve product quality, reduce maintenance frequency and costs with fast and accurate response performance.

DAT – 14 years in developing automation solutions for the plastic industry

DAT aims not only to sell individual machines or equipment but also to provide a solution that optimizes efficiency for customers. This means higher profits, better quality products, and peace of mind for customers to focus on their core business without worrying about issues arising from machinery systems. With an experienced team of engineers and a deep understanding of the plastic industry over 14 years of operation, DAT confidently offers the most effective solutions to meet customer requirements in the plastic industry.

- Improved technology, enhanced product quality.

- Increased efficiency and machine speed, thereby enhancing production productivity.

- Ease of operation, reduced waste.

- Stable machine operation, motor protection, reduced downtime and maintenance costs.

- Energy savings.

Conclusion

In the face of the current trend of plastic industry development amidst deep integration into the international economy, in general, to enhance internal strength and consolidate brand value, Vietnamese plastic enterprises need to actively strengthen research capabilities and invest in machinery according to new technology standards. With the right development focus, the Vietnamese plastic industry will become a self-sufficient industry with high and sustainable growth rates in the future.

DAT Technology Co., Ltd. (DAT) proudly stands as a leading provider of products, solutions, and services in the Vietnamese market for variable frequency drives, automation, elevator control, and solar energy.

- With over 14 years of experience in developing automation solutions, DAT has sold 500,000 products to over 7,000 customers nationwide.

- With a team of over 350 talented and experienced engineers

- DAT ensures prompt delivery and cost-saving technical support through a large inventory of variable frequency drives up to 1000kW and a nationwide technical service network available 24/7.

- The flexible process of “Replace first, formalities later”.

- DAT is a comprehensive strategic partner with the technology conglomerate INVT, collaborating from research and testing to product and solution introduction to the market.

- By deeply understanding and mastering technology, DAT optimizes processes, solutions, and services.

- DAT provides technical training programs, technology understanding, and machinery upgrade consultancy for customers.

For more detailed information, please visit www.dattech.com.vn and call the toll-free HOTLINE 1800 6567