Braking System – Equipment Ensuring Elevator Safety

Elevators are widely used in modern life, not only in buildings, apartments, hotels, etc., but also in households. Surely, the primary concern of customers when using an elevator is its safety. By providing information about the elevator brake system – an important device to ensure elevator safety, DAT hopes to give you peace of mind.

Role of Elevator Brake System:

Speed is a factor affecting the efficiency of elevator operation. If the elevator exceeds the allowable speed limit, it will pose dangerous impacts on users. There are many reasons leading to elevator overspeed, such as configuration errors, cable breakage, inadequate electric brakes…

The brake system in the elevator helps the elevator resolve overspeed conditions, ensuring safe operation.

|

|

|

Types of Brakes in Elevators:

- Electric Brake:

The electric brake is a device commonly installed on the elevator motor. The elevator’s electric brake is usually a normally closed electric brake. The opening and closing operation of the electric brake is coordinated smoothly with the motor’s operation.

Function of the electric brake:

Automatically stops the elevator cabin when power is lost. Keeps the elevator cabin balanced safely in a fixed position when called to a floor. In case the elevator runs at a speed exceeding the set limit due to any reason, the controller will quickly cut off the motor power, activating the electric brake to urgently stop the elevator.

Depending on different emergencies, the elevator controller will act on the electric brake and automatically diagnose faults to allow resumption of operation after an incident. In the event the elevator controller does not allow the elevator to continue operating or the rescue system fails due to a power grid failure, elevator technicians must come to inspect and handle the situation. If someone is trapped in the cabin, technicians may need to manipulate the motor brake to bring the cabin to the nearest floor and perform rescue operations to safely evacuate the person.

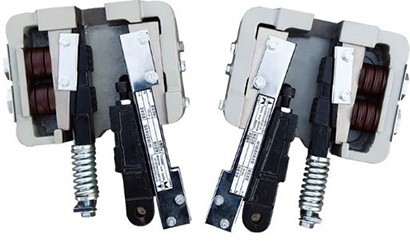

- Mechanical Brake:

The mechanical brake ensures elevator safety in case of power loss. In case the elevator cable breaks, the electric brake fails, or for any other reason, the control system malfunctions, causing the elevator to operate at an unsafe speed, a higher-level safety mechanism independent of electricity is necessary to ensure the highest level of safety for the elevator. Therefore, the mechanical brake was developed.

The mechanical brake operates based on using a speed control device (Governor) directly driven from the cabin via an inertial mechanism to control the elevator’s movement speed. The speed control device operates entirely independently of electricity to ensure the highest level of safety.

In the event of a situation causing the elevator to exceed the safe speed, the speed control device will respond to the request signal from the controller to cut off the motor power, the electric brake will close to tightly grip the pulley, and the speed control device will act on the mechanical brake mounted on the cabin, pressing the brake shoes against the guide rail. The cabin stops to ensure the safety of the users.

Electric and mechanical brakes are installed in different locations and have different operating principles. However, they share a common feature: to increase the safety of the elevator. Thanks to the electric and mechanical brake systems, in any situation or condition, the speed factor is always controlled in the best way possible to ensure maximum safety.

Due to the necessity of the electric and mechanical brake systems, these systems must always operate well and be checked and maintained on schedule to avoid causing unforeseen consequences due to brake malfunctions.

DAT – Provider of Modern Elevator Control Solutions

With many years of experience in the elevator industry, DAT provides control cabinet solutions using INVT EC3000 , ensuring the safety principles of elevator electric brakes such as smooth stopping and starting, accurate floor stopping, prevention of drift when the elevator is not operating, quick and accurate response to incidents. In addition, the EC3000 control cabinet also has a brake feedback function, helping to monitor and maintain the gap of the electric brake, avoiding situations where the electric brake does not operate or does not fully engage, causing friction, overheating the pulley, leading to premature brake and motor failure.

With over 14 years of effort in building a value ecosystem to increase efficiency for customers and partners, DAT is the leading provider of products and development solutions in the Vietnamese market in elevator control, frequency converters – automation, and solar energy. Over 6000 customers nationwide have highly appreciated DAT for its superior service “Better than the US, Better than Germany”, fast installation, maintenance, and repair within 24 hours. Therefore, DAT is confident that it will help your elevator operate stably, safely, and minimize potential incidents.

In addition, DAT is providing the integrated EC3000 elevator control system with many outstanding features compared to other solutions on the market:

- EC3000 has 2 standard cabinet types: with machine room and machine room-less (MRL). In addition, DAT’s R&D team can design non-standard cabinet configurations to meet all types of projects.

- Compatible with all types of gearless (PM) and geared (AM) traction machines.

- Compatible with all elevator configurations such as skyscrapers, residential buildings, hotels, hospitals…

- Can be installed for new elevators and upgrade old elevators.

- Various types of feature expansion boards are available, adding safety, intelligence, and convenience for users.

For more details, please contact the hotline 1800 6567 (free call) for quick support.

Mechanical Brake

Mechanical Brake Electric Brake

Electric Brake