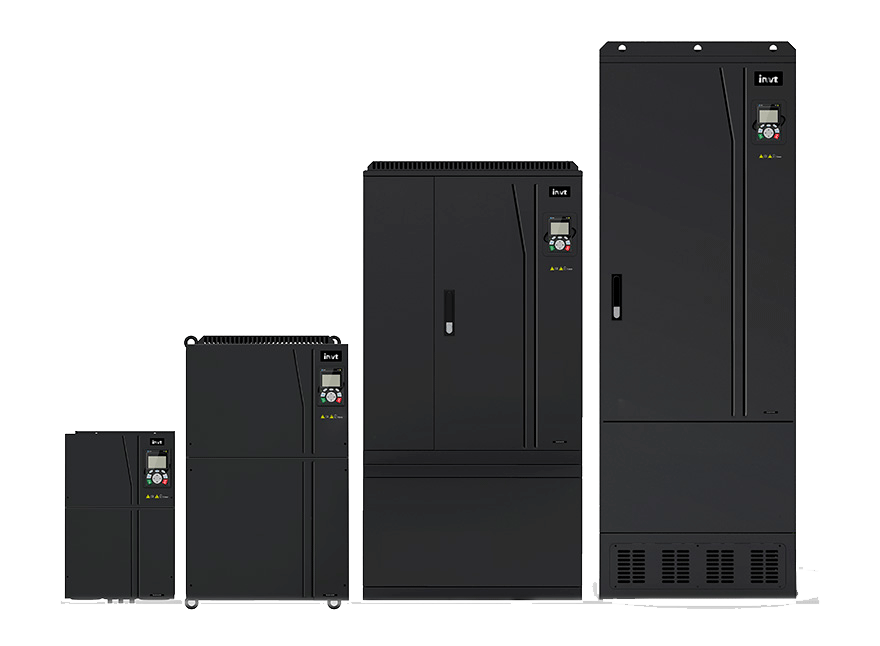

GD350 – New generation high-end multifunctional VFD

GD350 is INVT’s most advanced multi-function VFD series with the world’s leading vector control technology, meeting diverse control requirements with high efficiency. The product meets the technological requirements of the modern manufacturing industry 4.0, allowing users to monitor and operate the equipment anywhere with absolute precision and safety.

3 Phase Drives, 380V

- Free delivery within Ha Noi, Ho Chi Minh, Can Tho

- Free installation

| Brand: INVT | Warranty: 24 months |

| Specifications | Parameter | |

|---|---|---|

| Input | Input voltage (V) | 3P-380V (-15%)~440V (+10%), rated voltage: 400V 3P-520V (-15%)~690V (+10%), rated voltage: 660V |

| Input frequency (Hz) | 50/60 (Hz), permissible frequency range: 47 ~ 63 (Hz) | |

| Output | Voltage (V) | 0 ~ output voltage |

| Current (A) | Reference Rating Parameters | |

| Capacity (kW) | 3P-380V (-15%)~440V (+10%): 1.5~500kW 3P-520V (-15%)~690V (+10%): 22~630kW |

|

| Frequency (Hz) | 0~400Hz | |

| Specifications | Control mode | V/F, SVC, VC |

| Motor | Asynchronous Motor And Synchronous Motor | |

| Speed range | Asynchronous Engine: 1:200 (SVC)Synchronous Engine: 1:20 (SVC), 1:1000 (VC) | |

| Speed control precision | ±0,2% (SVC), ±0,02% (VC) | |

| Speed fluctuation | ±0,3% (SVC) | |

| Torque response | <20ms(SVC), <10ms(VC) | |

| Precise controls | 10% (SVC); 5% (VC) | |

| Starting torque | Asynchronous Motor: 0,25Hz/150% (SVC)Synchronous Motor: 2,5Hz150% (SVC); 0Hz/200% (VC) | |

| Overload capacity | 150% of the rated current: 60s 180% of the rated current: 10s 200% of the rated current: 1s |

|

| I/O | Analog input | 2 inputs, AI1: 0-10V / 0-20mA; AI2: -10- + 10V |

| Analog output | 1 output, AO1: 0-10V / 0-20mA | |

| Digital input | 4 frequency terminals: maximum frequency 1 kHz 2 high-speed pulse HDIA and HDIB |

|

| Digital output | 1 output Open Collector Y1 1 output of high speed HDO pulse, up to 50kHz |

|

| Relay output | 2 relay RO1A NO, RO1B NC, RO1C Common RO2A NO, RO2B NC, RO2C Common |

|

| Communication | Integrated RS485, USB Optional: CANopen, Profibus-D, Profinet, Ethernet / IP, Wifi, Bluetooth |

|

| STO | 2 INPUT STO, SIL2 | |

| Others | Protection level | IP20 (available in version IP54 for special applications in harsh dusty and wet environments such as HVAC, fans and pumps, stone and wood) |

| Installation | Supports wall mounting and hidden wall installations | |

| Working Environment Temperature | -10–50°C, normal working temperature: 40°C | |

| Dynamic Brakes | Integrated with power from 4kW — 37kW for 380V Optional integration with power 45kW-110kW for 380V Braking option for 660V |

|

| Card PLC | 6 DI, 2 DO, 2 relay | |

| Card I/O | 4 DI, 1 DO, 1 AI, 1AO, 2 relay | |

| EMC filter | For 380V, all models conform to IEC61800-3 C3 Standard with external filter compatible with IEC61800-3 C2 standard |

|

10.000+

15+

3000+

24h

Wide capacity range

• 380VAC 1.5kW ~ 500kW

• Scalable up to 3000kW

Precise controls

• Unique digital filter technology for highly precise control with the error of ± 1 pulse

• Supports many different types of encoders: incremental encoder, absolute encoder, Sin-Cos, rotary transformer, UVW …

High mobility: 1 inverter used for many applications

• Optional PLC card supports self-programming for different applications from simple to complex

• Diverse communication protocol, meeting the requirements of each customer easily

Application of digital technology: towards production 4.0

• Remote control and monitoring via the internet

• Support to access and set up device parameters on mobile phones via bluetooth

Reduce costs and save installation space

• Built-in dynamic braking unit with inverter up to 37KW, available space to accommodate the brakes with inverters from 45 ~ 110KW, saving installation costs

• Integrated DC reactor with capacity up to 110kW

Safe Torque Off (STO) function ensures safe and reliable operation