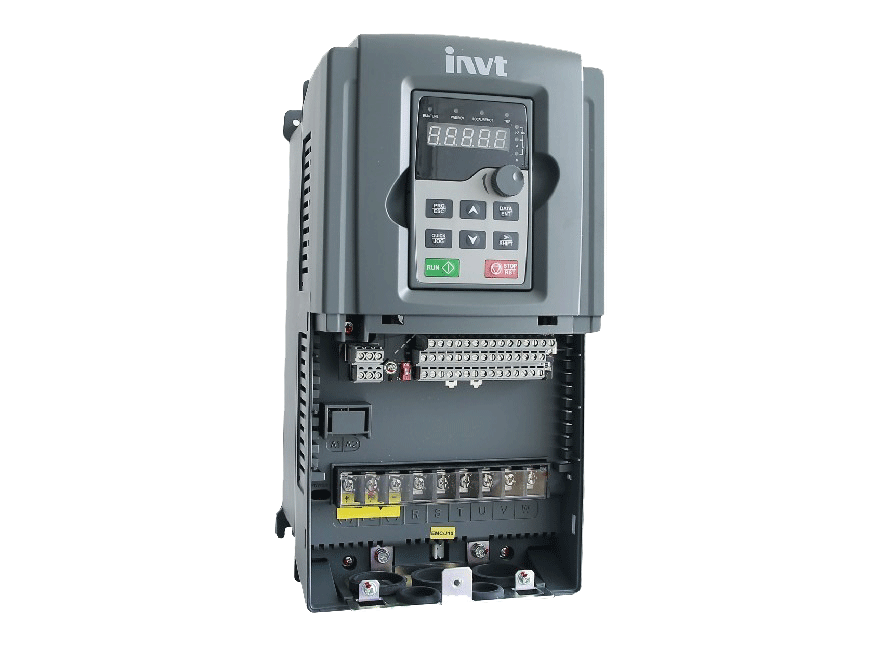

GD35 series high performance closed loop vector VFD

Goodrive35 close loop vector VFDs can drive induction motors and permanent magnet synchronous motors. It is mainly used in the applications which need spindle positioning, simple servo and high performance control for accurate speed control, starting and rapid speed response.

3 Phase Drives, 380V

For fastest support. Please Call 1800 6567 (Free)

- Free delivery within Ha Noi, Ho Chi Minh, Can Tho

- Free installation

| Brand: INVT | Warranty: 24 Months |

| Function description | Specification | |

| Capacity range | 1.5~630KW | |

| Input | Input voltage (V) | 3P, 380VAC (±15%), 1.5-500kW 3P, 660VAC (±15%), 22-630kW |

| Input frequency (Hz) | 47~63Hz | |

| Output | Output voltage (V) | 0~input voltage |

| Output frequency (Hz) | 0~400Hz | |

| Motor type | Asynchronous motor, permanent magnet synchronous motor | |

| Technical control performance | Starting frequency / starting moment | 0Hz/200% |

| Control mode | SVPWM, SVC, VC | |

| Speed range | 1:1000 | |

| Overload capacity | 60s for 150% of rated current; 10s for 180% of rated current; 1s for 200% of rated current; |

|

| Controller functions | PID control function, multi-level speed function: 16 preset speed levels, position running, synchronous running, tension control … | |

| Speed accuracy | ± 0.02%, accurate torque control of 5%. | |

| Source set frequency | Keypad, analog input, pulse input, modbus communication, profibus communication, multi-level speed, simple PLC and PID. Combination can be performed between multiple inputs and switching between different inputs. | |

| Carrier frequency | 2~15KHz | |

| Response time | <10ms. | |

| Speed detection function | Smooth start on running engine | |

| Noise Filter | Built-in C2, C3 | |

| Dynamic brake | Integrated brakes with voltage 380V (≤30KW). | |

| Communication | Modbus RTU, Profibus,Canbus, Ethernet. | |

| Periphral interface | Digital input | 8 digital inputs that accept ON – OFF value, and can reverse the status of NO or NC. |

| Pulse input | 1 high frequency pulse receiving input, support both PNP and NPN. | |

| Reference pulse input | Input receiving pulse in position running mode and encoder pulse output. | |

| Analog Input | Two (AI1, AI2) 0~10V/0~20mA, one (AI3)-10~10V | |

| Analog output | Two (AO1, AO2) 0~10V /0~20mA | |

| Relay output | Two programmable relay outputs:

-RO1A NO, RO1B NC, RO1C common port -RO2A NO, RO2B NC, RO2C common port |

|

| Open collector output | HDO (ON – OFF output or high frequency pulse output) and Y output. | |

| Integrated pulse encoder feedback | + A1: Encoder 5V, read 200kHz pulse. + B1: 12V encoder, read pulse 100kHz. + C1: 24V encoder, can read 100kHz pulse. + D1: Encoder 5 ~ 12V, read 500kHz pulse. + H1: Rotary transformer encoder, reads 300kHz pulse. |

|

| Protection function | Protection against incidents such as over current, high voltage, under voltage, over temperature, phase loss, phase difference, output line breakage, overload etc. | |

| Special functions | Self-voltage stabilization function (AVR) | Automatically stabilizes the output voltage when the supply voltage fluctuates abnormally. |

| Power saving function | – The function automatically saves electricity when the engine is overloaded – Increase engine power factor. |

|

| Control function brake | Brakes kinetic energy, wins on excitation, wins DC | |

| Load balancing function | When multiple motors are pulling the same load, this function helps balance the distributed load across the motors by reducing the speed down based on the increased value of the load. | |

| Torque compensation function | Increases the torque characteristic of V / F control when the motor works at low speed. | |

| Functions help the system to operate continuously | Automatically reset the error according to preset times and times Maintains operation during transient power outages and wide operating voltage range suitable for flickering power locations. |

|

| Function of inspection and supervision | Connect a computer to monitor the operation as well as parameter settings for the inverter thanks to INVT Studio software, HCM. | |

10.000+

Customers Nationwide

17+

Year Of Experiences

3000+

Warehouse Area Above 3000 m² Is Always Available Items That Help Customers Fast Project Progress

24h

24 Hours To Complete All Processes, Procedure Is Quick And Flexible

- VF Sensorless Vector Control and closed-loop vector control

- Compatible with synchronous and asynchronous motors

- Support incremental encoders, rotating transformer encoders for closed-loop vector control

- External LED keypad to copy parameters; Optional LCD keypad provided

- Standard C3 filters; Optional C2 filters

- Support the spindle positioning, rigid tapping and simple servo functions

- Optional PG card with the functions of pulse reference and frequency-division output

- Standard Modbus, optional Profibus, CANopen and Ethernet

Applications:

Textile, CNC lathe, Woodworking equipment, Paper machine,Printing and packaging, any situations of high performance vector control.

Textile, CNC lathe, Woodworking equipment, Paper machine,Printing and packaging, any situations of high performance vector control.