Is there a VFD that can suit every application?

The industry is a key component of the economy, serving as a large-scale production sector driven by robust advancements in science, technology, and engineering. Industrial activities are highly diverse, with each sector having unique technological requirements and characteristics. In the past, specialized VFDs had to be used for each specific application, making it nearly impossible to intervene or program according to specific needs.

Understanding the challenges faced by customers, in 2019, the INVT group proudly introduced the GD350 super VFD with unlimited expandability through PLC cards, PG cards, and diverse communication capabilities, suitable for almost all types of motors. A truly versatile VFD for every application, providing optimal choices for customers.

GD350 – An intelligent super VFD integrating modern technology for diverse needs

As the most anticipated product of 2019 by INVT, INVT GD350 VFD is developed and manufactured on the most advanced processing platform of INVT. It applies unique digital filtering technology for precise control, supports various encoder types, and optional PLC cards for custom programming in different applications, coupled with diverse communication protocols. It easily combines with wireless control features, cloud computing, and IoT technology, meeting the requirements of each customer effortlessly.

GD350 VFD with its new optimized control principle is widely applied in various industries:

Textile and fiber industry: GD350 meets the diverse and complex processing requirements of applications such as brush machines, fiber assembly machines, fiber winding machines, circular knitting machines, flat knitting machines, fiber dyeing machines, fabric dyeing machines, centrifugal machines, and needle stretching machines. The integrated brake and DC resistance reduce power consumption, and its compact size saves installation space.

Packaging and printing industry: With applications like blow molding machines, flexo printing machines, copper tube printing machines, offset printing machines, shaping machines, cutting machines, paper slitting machines, wave-making machines, GD350 features expandable capabilities to easily meet customer customization needs. The PLC card with a 128kB memory capacity supports custom programming for various applications, providing simple and highly accurate servo control functions, with an error rate below 1 pulse. It integrates the STO safety function, complying with international standards for enhanced safety and reliability.

Construction machinery industry, including steel industry machinery (steel drawing machines, rolling mills, strip discharge), brick industry machinery, and woodworking machinery. The unique I/F control function operates with a constant current source suitable for controlling multiple motors simultaneously, especially for high torque applications at low speeds.

GD350 can also be widely applied in the metalworking industry and other sectors. The use of the latest motor control technology ensures stable control.

What makes the GD350 super VFD powerful?

The era of Industry 4.0 demands innovative thinking and advanced technology. INVT has quickly incorporated breakthrough features into its VFD to meet the diverse needs of modern production. With decades of experience, alongside technological factors, high performance is always present in every INVT product, providing customers with optimal and cost-effective solutions.

To effectively address applications ranging from basic to complex, INVT has equipped the GD350 with several special features:

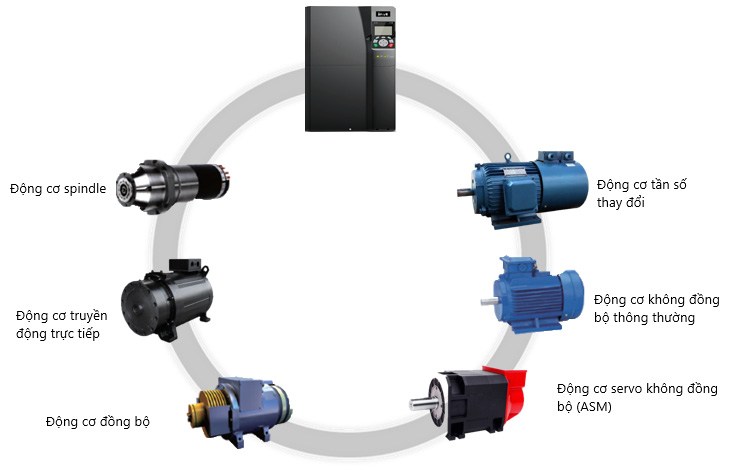

Supports SVC and VC (closed-loop) control modes for both synchronous and asynchronous motors, allowing GD350 to control various motor types: asynchronous motors, asynchronous servo motors (ASM), synchronous motors, direct-drive motors, spindle motors, variable frequency motors, etc., with high efficiency.

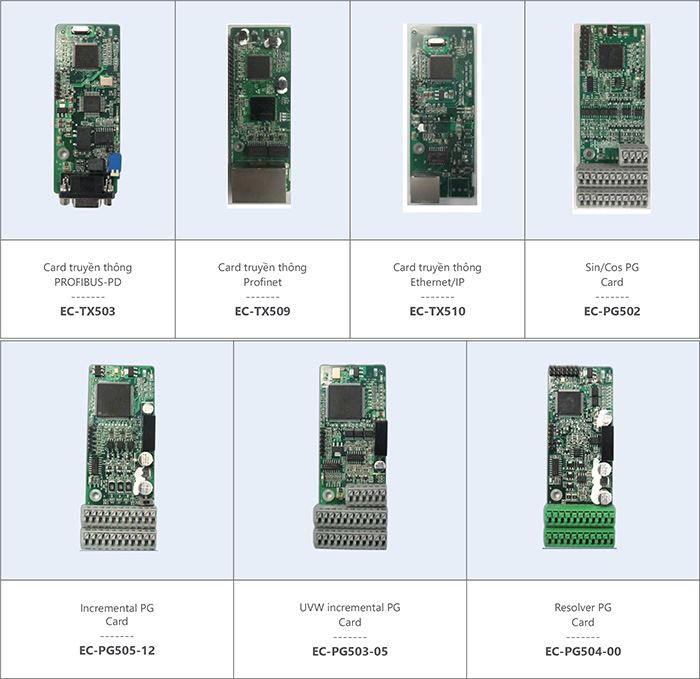

Supports communication interface cards, including Profibus-DP, Profinet, CANopen/CAN master/, and Ethernet/IP, while also supporting PG cards for various encoders such as incremental encoders, rotary transformer encoders, SIN/COS encoders. This ensures easy integration into any environment and communication with any control device. Up to 2 expansion cards can be attached to VFDs with power below 5.5kW, and up to 3 expansion cards for power from 7.5kW and above. The expansion card sizes are the same, facilitating installation.

Supports optional PLC cards with up to 128kB of memory, allowing GD350 to replace PLCs in simple control systems. It can write small automatic procedures and customize the VFD according to the machine’s application, saving significant investment costs. The VFD uses the CODESYS platform, supporting 6 PLC programming languages: IL, ST, FBD, LD, CFC, SFC.

With these outstanding features, GD350 super VFD is a special product suitable for various industries, especially for machine manufacturers and system integrators. It meets the needs of research, innovation, customization, and exclusive solutions for different application requirements with low costs.

For product inquiries and solutions, customers and partners are encouraged to contact DAT at the toll-free hotline 1800 6567 for prompt assistance.