Is it possible to use a VFD to replace a Servo Drive for controlling a Servo motor?

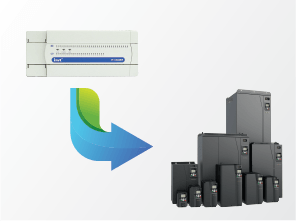

The development of modern industry has led to the increasing use of servos in various machinery systems. In many cases, servo drives may fail while the servo motors are still functioning properly, and it may not be possible to purchase a replacement drive (due to discontinued product lines or long delivery times). Replacing the entire servo system when only the drive has an issue is not something any business desires due to the high cost. So, can cost be saved by using a VFD to replace a servo drive for controlling servo motors? The answer is absolutely yes.

When is it necessary to use a VFD to replace a servo drive?

The need to use a VFD as a replacement for a servo drive typically arises when the drive is faulty, but the supplier does not have replacement units available, or the old drive model has been discontinued. In such cases, the user might have to stop the machine for an extended period or replace the entire servo system, incurring significant costs. There are also cases where some entities acquire used servo motors (without drives) at a low cost and seek suitable VFDs to control these servo motors for resale. In reality, this is a significant demand, and it is of great interest to machine builders and manufacturers.

Currently, there are high-end VFDs available on the market that are specially designed to control servo motors effectively, addressing the cost-saving challenge when servo drives fail.

Is it true that any VFD can control servo motors?

The answer is no. To replace a servo drive, a VFD must have specific features that are compatible with the operation of servo motors.

Servo motors are typically permanent magnet synchronous motors with rotors made of permanent magnets. The rotor rotates in synchronization with the rotating magnetic field generated by the stator and operates based on closed-loop feedback from an encoder. To control a servo motor, it’s essential to have a controller capable of handling closed-loop feedback.

Most common VFDs available today are primarily designed for controlling three-phase asynchronous motors. If these types of VFDs are used with servo motors, issues such as jerky motion, vibration, and loud noises can occur. Increasing the frequency with such VFDs can lead to the motor overheating, and the VFD may report overcurrent faults. In some cases, even if the servo motor manages to run, its performance can be severely compromised.

To successfully replace a servo drive with a VFD, the VFD must meet the following requirements:

- It must be capable of high-level closed-loop feedback control with specialized vector control algorithms for both AC and PM motors.

- It should accept control signals from a controller and read the encoder signals from the current servo system.

Does using a VFD instead of a servo drive affect the operation of servo motors?

If the right type of VFD is selected, it can completely replace a servo drive for controlling servo motors without affecting the motor’s control capability or its overall performance, as well as the operation of the existing system.

Currently, in the market, there are the GD35 and GD350 series of VFDs by INVT, which can be used to replace servo drives for excellent servo motor control. These VFDs enable servo motors to run smoothly, maintain precise positioning, minimize heat generation, and provide excellent performance for starting, stopping, and acceleration/deceleration.

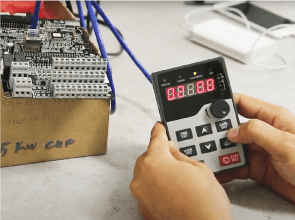

GD35 is a high-end closed-loop VFD that offers precise control for both AM and PM motors. It supports various encoder signals like ABZ, Resolver, Sin/Cos, with a frequency range of up to 400kHz. Additionally, it integrates special control functions such as speed, position, torque, speed/torque, position/speed, and position/torque, ensuring high accuracy and outstanding electromagnetic compatibility while delivering extremely fast acceleration and deceleration times.

GD35 VFD

GD35 VFD

The GD350 is a smart, multi-functional high-end VFD by INVT, equipped with world-leading Vector control technology. It can control various types of motors, including asynchronous, synchronous, PM, direct-drive, and spindle motors, with high efficiency. Besides features similar to GD35, GD350 also comes with a PLC card and up to 128k program storage, using the CODESYS platform that supports six PLC programming languages. This versatility allows it to cater to various customer customization needs during the production process, ultimately reducing the cost of installing new equipment.

GD350 VFD

GD350 VFD

In recent years, DAT has successfully used GD35/GD350 VFDs to replace servo drives, providing seamless control for various types of machinery in multiple industries. This includes replacing servo drives in hydraulic plastic molding machines, printers, packaging machinery (carton, nylon, PP), manufacturing equipment, CNC machines, textile dyeing machines, food processing, wood processing, and paper processing. This solution allows factories to retain their existing servo motors, only requiring a drive replacement in the event of a system failure, resulting in significant cost savings, optimized efficiency, and reduced machine downtime.

DAT’s team of engineers has executed projects involving the use of GD350 to replace servo drives in hydraulic plastic molding machines

DAT’s team of engineers has executed projects involving the use of GD350 to replace servo drives in hydraulic plastic molding machines

Some key points to consider when using a VFD to replace a servo drive:

- Configure and adjust the VFD parameters to match the servo motor’s specifications.

- Limit the voltage level on the VFD to align with the servo motor’s voltage requirements.

- Choose a VFD power rating that is suitable for the servo motor’s power rating.

- Thoroughly read the manufacturer’s installation and operation documentation before use.

DAT is currently the exclusive provider of these VFD solutions and products in the Vietnam market.

For any inquiries or if you wish to learn more about this specialized control solution, please feel free to contact us directly via the toll-free hotline at 1800 6567 for detailed assistance.