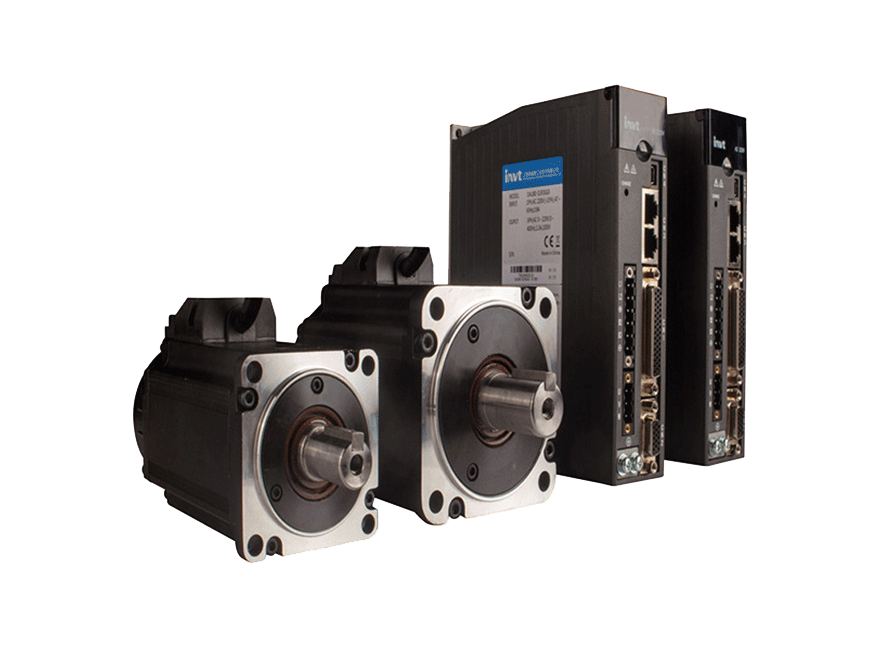

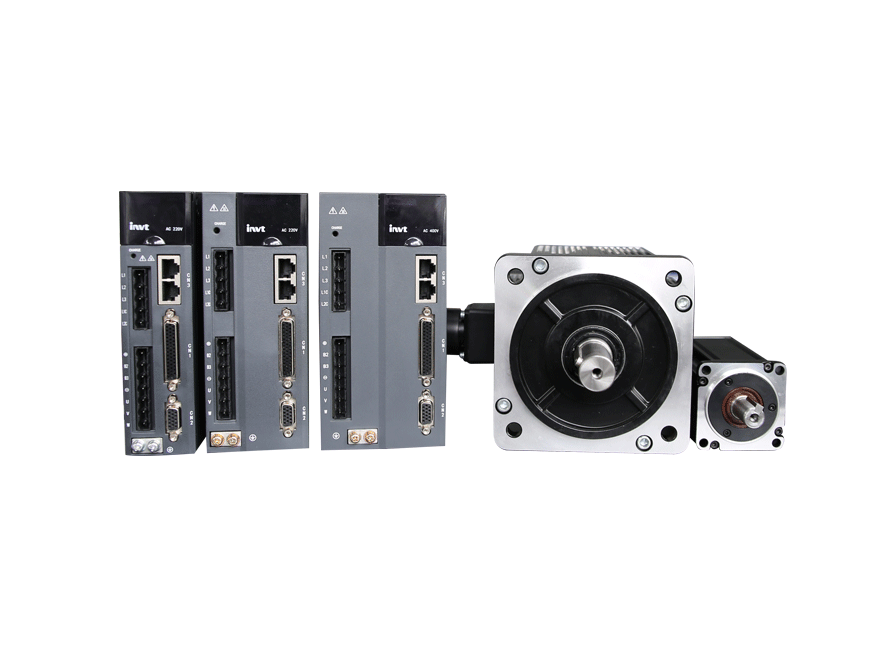

DA180 – New Generation AC Servo System

DA180 is INVT’s new generation (0.1 – 1kW) multi-function multi-function servo product, used for simple and flexible applications. With special features and diverse, high-speed communications, the DA180 provides a wide range of efficient, competitive solutions that fully meet the requirements of intelligent control and high performance.

For fastest support. Please Call 1800 6567 (Free)

- Free delivery within Ha Noi, Ho Chi Minh, Can Tho

- Free installation

| Brand: INVT | Warranty: 18 months |

| Servo DA180 (100W-1000W) | |||||

| Power supply | Input power supply 220V | 1P/3P AC220V(-15%)–240V(+10%) 47Hz–63Hz | |||

| Display | Control signals | Input | 10 inputs (function can be configured by parameter setting) | ||

| Output | 4 outputs (function can be configured by parameter setting) | ||||

| Analog signal | Input | 2 input 12 bit | |||

| Pulse signal | Input | 1 group (modes: collector pulse or differential pulse) | |||

| Output | 1 group (differential pulse, A +, A-, B +, B-, Z +, Z-) | ||||

| Communication | USB | 1: 1 communication with PC software (standard) | |||

| RS485 | 1: n RS485 communication (standard) | ||||

| CANopen | 1: n communication CANopen (standard) | ||||

| Controller mode |

|

||||

| Function | Position control | Control input |

|

||

| Control output | Output position complete … | ||||

| Pulse input maximum frequency | Optical input: 4Mpps differential pulse input, 200kpps collector pulse input | ||||

| Pulse input mode |

|

||||

| Electronic gearbox | 1/10000-1000 times | ||||

| Filter |

|

||||

| Analog input | Input torque limit command: torque limit can be executed independently clockwise / counterclockwise | ||||

| Vibration control | Terminal vibration can be controlled and 5-200Hz overall vibration | ||||

| Pulse output |

|

||||

| Speed control | Analog input | Speed input command | Can be controlled by analog input after setting based on analog voltage DC ± 10V | ||

| Limit input torque | Can be independently arranged clockwise/counterclockwise. | ||||

| Internal speed control command | 8 speed steps can be set according to digital input control | ||||

| Adjust the ACC / DEC of the internal speed command | Set acceleration / deceleration time and set S-curve | ||||

| Set zero speed | In speed mode, it is possible to set to act as speed mode and position mode | ||||

| Speed command filters | A delay filter of the speed analog input | ||||

| Zero drift speed command | Zero deviation control against external noise | ||||

| Torque control | Control input | Input reaches zero speed | |||

| Control output | Reach speed | ||||

| Analog input | Torque input command | Analog torque command input, gain and polarity can be set based on analog voltage | |||

| Speed limit input | Analog speed limit | ||||

| Speed limit | Set speed limit by parameter | ||||

| Torque setting filters | An analog input torque delay filter | ||||

| The torque command floats zero | Zero deviation control against external noise | ||||

| Internal location | Input | Internal position 128 bits, position can be set via communication | |||

| Install the property | 1. Position 2. Speed 3. ACC time 4. DEC time 5. Dwell time 6. Output status 7. Operation mode |

||||

| Original mode | 1. LS signal 2. Z phase signal 3. LS signal + Z phase signal 4. Torque limit signal signal |

||||

| Protect | Hardware protection | Over voltage, low voltage, over current, over speed, overload, brake resistor overload, over temperature, encoder error … | |||

| Protection and error history | 1. Record up to 10 errors. 2. Main parameters can be logged when an error occurs |

||||

| Environment | Operating temperature | 0 – 45℃ | |||

| Storage temperature | -20 – 80℃(no freezing) | ||||

| Operating / storage humidity | ≤90%RH (no dew condensation) | ||||

| IP protection level | IP20 | ||||

| Height | Below 1000m above sea level | ||||

| Vibration | ≤5.88m / s2, 10 – 60Hz (not allowed to work at resonance) | ||||

10.000+

Customers Nationwide

15+

Year Of Experiences

3000+

Warehouse Area Above 3000 m² Is Always Available Items That Help Customers Fast Project Progress

24h

24 Hours To Complete All Processes, Procedure Is Quick And Flexible

– High speed response (up to 2.0kHz).

– Internal position control mode with 128 steps of internal position coordinated with terminal input signal (extended I / O or bus).

– Light and convenient (45% lighter than the DA200).

– High precision with 17bit absolute encoder.

– Diverse communication standards: Modbus, CANopen …

– Adaptability to the environment: natural cooling with capacity from 400W or less.

Low vibration frequency control: eliminates mechanical resonance between low frequencies and mechanical vibrations to increase efficiency in operation.

– Internal position control mode with 128 steps of internal position coordinated with terminal input signal (extended I / O or bus).

– Light and convenient (45% lighter than the DA200).

– High precision with 17bit absolute encoder.

– Diverse communication standards: Modbus, CANopen …

– Adaptability to the environment: natural cooling with capacity from 400W or less.

Low vibration frequency control: eliminates mechanical resonance between low frequencies and mechanical vibrations to increase efficiency in operation.

The DA180 system is widely used in industry, especially medical mask making machines and some machinery in the steel industry such as automatic wire mesh welding machines, capsule breakers, aluminum bar grating machines, plasma cutting machines, machines CNC. In addition, DA180 is also used in the food processing industry such as the application of measuring the length of the packaging machine, controlling the valve in the filling system …

Servo controller has been used and appreciated by customers for many years thanks to its outstanding control feature with high accuracy, engine protection, helping customers to save production costs, lower production costs. products, improving competitiveness in the market.

When using the servo motor, you will receive professional technical service from DAT’s distribution system nationwide, receive technical advice, design, installation, manuals and technical documents free of charge. fee.