Replacing a different brand VFD: What to consider?

VFDs are increasingly used in various industries and, like other electronic devices, they cannot last indefinitely. Eventually, they will malfunction, making it necessary to replace them. To facilitate and maximize the efficiency of the replacement process, consider the following key points:

1. Selecting a suitable VFD from a different brand:

- Based on requirements:

Identify the type of load being controlled, such as heavy, medium, or light load. Additionally, determine the operating mode of the machinery, whether it operates in the long term or short term.

– Short-term mode: The motor undergoes continuous acceleration/deceleration, frequent starts/stops, and continuous direction changes. Therefore, it is necessary to choose an VFD with high overload capacity.

– Long-term mode: The motor operates at a constant speed with minimal changes during operation.

- Based on financial capabilities:

The market offers various VFD models from European, Chinese, Taiwanese, etc., manufacturers with competitive pricing. Choose an VFD with a reasonable price but ensure that it is distributed by a reputable supplier with reliable warranty and maintenance policies, as well as attentive customer service.

- Based on technical specifications:

Choose an VFD that is compatible with the type of motor and motor power. Specifically, understand whether the motor is synchronous or asynchronous, single-phase or three-phase, AC or DC.

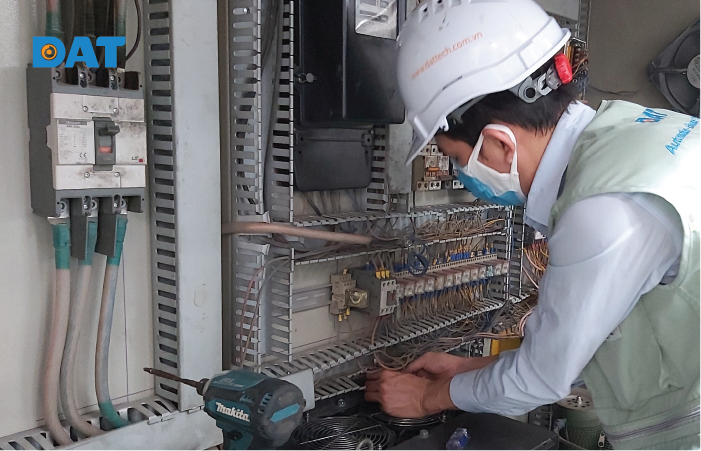

2. Considerations during the replacement process:

- Identify the cause of the current VFD failure

Before replacing the VFD, determine the main causes of the failure of the current VFD. Failing to identify the cause may result in installing a new VFD that continues to experience issues.

Some factors to consider include: unstable power supply to the VFD, the environmental presence of dust around the VFD, high humidity, and the motor experiencing load jams. Check the error codes of the current VFD to determine the root cause.

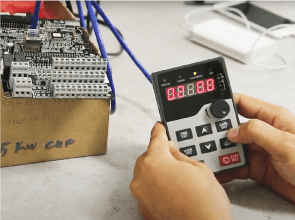

- Choosing the appropriate technical parameters for replacement

Before replacing the VFD, determine the technical parameters of the current VFD, including power, input and output voltage, and size.

Important information to ascertain includes the control mode of the VFD, encompassing communication protocols and closed/open-loop control.

Verify the size of the current VFD to avoid situations where the new VFD is larger and cannot be installed in the electrical cabinet.

For some VFDs with closed-loop control using an encoder card: Select an VFD that supports reading encoder signals.

Some accessories that come with the VFD include braking resistors, and AC/DC reactors.

3. Cases where replacement may not be feasible:

Some cases involve communication protocol differences, making it challenging to replace VFDs from different brands.

4. Additional considerations:

When replacing with a different brand VFD, careful examination and consultation with experienced engineers are essential. The replacement product must be genuine and of high quality. Choose a reputable supplier that provides dedicated and prompt support in case of issues.

For any inquiries, please contact the hotline at 1800 6567 (free of charge) for quick assistance.