Control solutions that increase the efficiency and accuracy of flexo machines

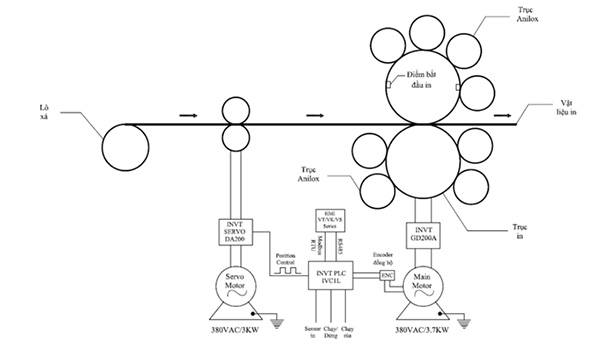

The solution using INVT’s PLC/HMI programmer, DA200 servo and inverter GD200A to synchronize the axes of Flexo printers achieves high efficiency and accuracy, helping to improve product quality.

Flexo printing is the main method for printing PP, PE packaging labels, cartons, decals, labels, rolls of films, labels, stickers. Flexo printing is a direct printing technique thanks to the embossed plate, the ink is supplied to the printing plate by the anilox shaft.

The old operating method, the system operates separately, and the batches have not been synchronized with each other.

CUSTOMERS’ DIFFICULTIES

The system is difficult to operate and is not synchronized, the uniform alignment of the operation of the printer parts becomes complicated, causing difficulties, taking a long time for the operator, the efficiency is not high, it takes a lot of time to calibrate, increasing the amount of waste.

SOLUTION ANALYSIS

- The inverter GD200A drives the motor to rotate the print shaft, which drives the ink batches. On this shaft, there is an encoder that is responsible for measuring the long speed to synchronize with the rear PP bag-level Servo system.

- The Servo system is responsible for feeding the workpiece so that the length and speed of the print axis is correct

- PLC & HMI control system: PLC receives and processes signals such as print point detection sensor, synchronous encoder, machine speed, inverter run/stop/delay control.

- In addition, the system also has Servo slow mode to put the bag in, slow down the main motor to adjust the printing point and some other running conditions.

SOLUTION ADVANTAGES

- Easy operation system with intuitive HMI display

- Speed synchronization, communication with PLC/HMI

- Improve productivity and product quality

- Reduce waste, reduce mechanical wear

- Do note depend on workers running the machine

Take a look at DAT's specialized solution design process.

Contact an expert

If you need advice and learn about DAT’s solutions, please contact 1800 6567 to meet with experts today.

Products for solutions

Solution relate:

10.000+

15+

3000+

24h

Let's go with DAT

24/7 SUPPORT

Hotline 1800 6567