Invest in the most effective control solution for ball mills?

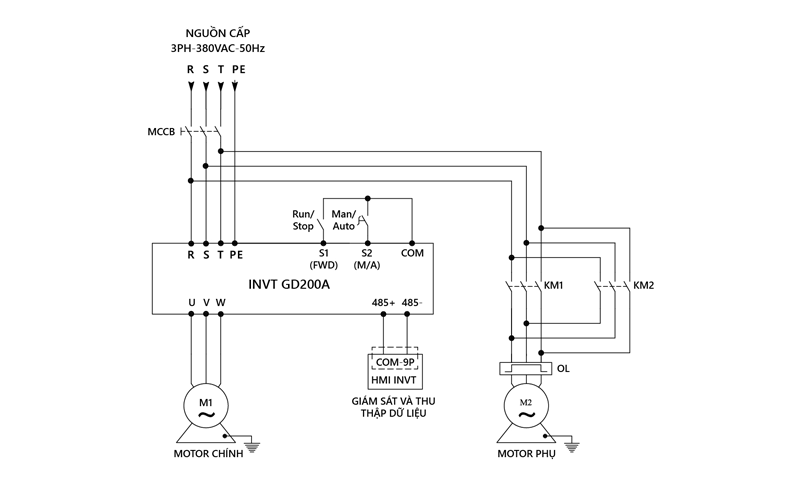

The solution uses INVT’s GD200A inverter to control the ball mill, helping to improve working efficiency and save energy.

Ball mill is equipment used to grind dry and wet materials in many industries such as cement, refractory materials, silicates, new building materials, fertilizers, non-ferrous metals, glass, ceramics, etc.

The old operating method, the ball mill is usually controlled with the following method:

- Main motor: Use Star/Triangle control method or soft start. Motor always operates at 100% rated speed.

- Auxiliary motor: Directly started and performed only in the beginning before grinding takes place.

CUSTOMERS’ DIFFICULTIES

- Difficult to start, large starting current causes mains voltage drop. Cannot work when the power grid is unstable or unstable.

- It is easy to damage mechanical parts such as Puly, bearings, etc.

- The engine is always running at maximum capacity, causing energy loss

- Time consuming, maintenance and service costs

SOLUTION ANALYSIS

- Use GD200A inverter for main motor to start smoothly and control the speed of each grinding stage of the machine.

- Collection and storage of data Design a system that collects and stores the speed and time of the crushing stages of each type of crushed material through the HMI display.

SOLUTION ADVANTAGES

- Smooth start, avoid mains voltage drop

- Protection of engines and mechanical structures

- Easy to operate, quiet operation

- Save up to 10% on electricity costs

- Time saving, maintenance and service costs

- Complete solution, available warehouse, 24/7 service

Are you still hesitant, worried about efficiency?

Take a look at DAT's specialized solution design process.

Take a look at DAT's specialized solution design process.

Contact an expert

If you need advice and learn about DAT’s solutions, please contact 1800 6567 to meet with experts today.

Products for solutions

Solution relate:

10.000+

Customers

15+

Years Of Experience

3000+

Warehouse Area Above 3000 m² Is Always Available Items That Help Customers Fast Project Progress

24h

24 Hours To Complete All Processes, Procedure Is Quick And Flexible

Let's go with DAT

24/7 SUPPORT

Professional support team, ready to serve 7/7

Hotline 1800 6567

Free consultation call center for DAT's customers. Call us now.

Email: [email protected]

All customer requests sent to DAT's email are resolved and answered as quickly as possible.