Comparing VFDs and Soft Starters: Features and Applications

Electric motors often require a substantial amount of energy to start and quickly reach their maximum speed. Both soft starters and VFDs can be used to reduce inrush current and limit torque to protect mechanical equipment, prevent grid voltage drops, and extend the lifespan of motors when dealing with high-power motors or continuous start-stop applications. So, when should you use a VFD, and when should you opt for a soft starter?

What Is a Soft Starter? How Does a Soft Starter Work?

A soft starter is a device used to assist in the startup process of AC electric motors, ensuring the motor is protected from damage caused by sudden high inrush currents during startup and avoiding grid voltage drops by gradually increasing the voltage supplied to the motor from a predetermined level to the rated voltage (opposite for soft stopping).

The operation principle of a soft starter:

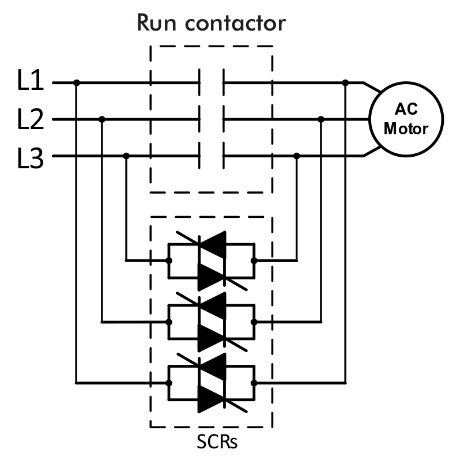

A typical soft starter consists of three pairs of inverse parallel thyristors (SCRs) connected in parallel. In the off state, the thyristors block the current flow. When in the on state, they gradually increase the firing angle (the angle at which the conducting thyristors are triggered), allowing current to flow slowly, thereby starting the motor and gradually increasing its speed. Voltage is controlled by adjusting the firing angle. When the valve is fully open, the voltage reaches the rated voltage, allowing the motor to reach its maximum permissible speed. Since the motor torque is proportional to the square of the voltage, and current is proportional to voltage, the acceleration torque and startup current are limited by adjusting the effective voltage.

Once the motor reaches its rated speed, the bypass contactor within the soft starter closes, automatically bypassing the thyristors to the grid without going through the thyristors.

Soft starters are typically used in applications where:

- The motor needs to accelerate and increase torque gradually during startup or shutdown

- Limiting high inrush currents is necessary for large motors to avoid issues with grid voltage drops or motor damage

- Controlling the startup and stopping speed is essential to prevent sudden torque or tension on mechanical systems such as conveyors, belt-driven systems, and couplings

- Pump motors are used to avoid water hammer during startup, preventing pipe damage

The benefits of a soft starter include:

- Supporting startup processes and reducing grid voltage drops

- Protecting the motor from overcurrent, overvoltage, phase loss, input and output phase errors, non-load conditions, and short circuits

- Increasing the lifespan of the motor and mechanical components

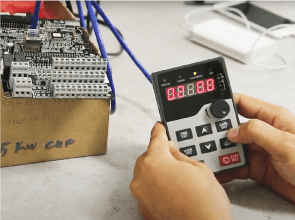

What Is a VFD? What Are the Benefits of Starting with a VFD?

A VFD is a device that changes the frequency of the current supplied to the motor, controlling its speed continuously, not just during startup. It offers precise speed control throughout the motor’s operation

The operating principle of a VFD:

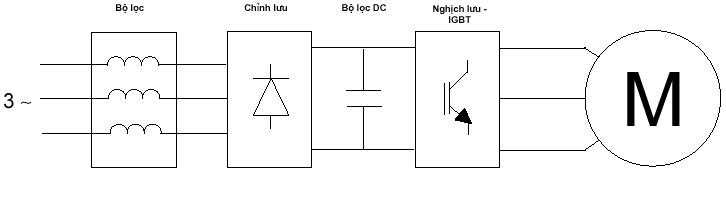

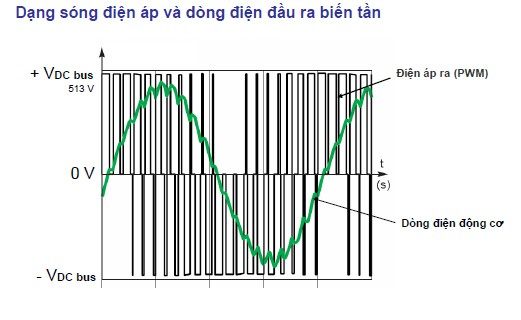

The operation of a VFD is relatively straightforward. First, a single-phase or three-phase AC power supply is rectified and filtered into a flat DC voltage using diode rectifiers and capacitors. This DC voltage is then inverted (inverted by pulse-width modulation) into a symmetrical three-phase AC voltage using insulated gate bipolar transistor (IGBT) technology. This AC voltage can vary in magnitude and frequency, allowing for continuous control of the motor’s speed based on the input from the control panel.

Hệ thống điện áp xoay chiều 3 pha ở đầu ra có thể thay đổi giá trị biên độ và tần số vô cấp tuỳ theo bộ điều khiển, từ đó thay đổi tốc độ động cơ theo yêu cầu trong suốt quá trình hoạt động.

The advantages of using a VFD include:

- Smooth motor startup with adjustable acceleration and deceleration times

- The ability to change the motor’s speed and perform “soft stopping” during operation

- Comprehensive motor protection features, including overcurrent, overvoltage, phase loss, phase reversal, and more

- Energy-efficient operation, resulting in energy savings and reduced operating costs

- Integration of various control functions to enhance technology and increase production efficiency

So, when should you use a VFD, and when should you use a soft starter?

To choose the appropriate starting method for your application, you must determine your specific needs, usage requirements, and balance the investment cost to achieve optimal efficiency. Review the comparison table between VFDs and soft starters below for a more objective evaluation before making a decision:

| VFD | Soft Starter |

|---|---|

| It is possible to change the motor speed flexibly, reverse the motor not only during startup and stopping but also throughout the operation of the equipment. | It only has the effect of accelerating or decelerating during startup and stopping to provide soft starting or stopping, and it cannot reverse the motor |

| The adjustment of acceleration and deceleration time is more flexible, with a wider adjustment range, making motor startup extremely smooth | The adjustment range for acceleration and deceleration times is narrower and startup is heavier, especially with large motors, making startup more challenging |

| It offers more motor and mechanical system protection functions | It has fewer motor protection functions, only basic protection features |

| You can start the motor as many times as you want in a day and throughout the equipment’s lifespan without affecting the motor and mechanical system | Depending on the motor’s power and the plant, the number of startup cycles may be limited |

| It changes the motor speed by varying the frequency, so it doesn’t affect the starting torque | It changes the motor speed by altering the voltage, which weakens the starting torque, so attention must be paid to load factors when selecting soft starters |

| A single VFD can be used to adjust the speed and perform soft stops for multiple motors | A soft starter is used only for a single motor |

| It has a larger size and occupies more space | It is more compact compared to VFDs with the same power rating |

| It has a higher cost | It has a lower cost |

So, the common feature of soft starters and VFDs is that they are both used to control motors (primarily speed) smoothly and save energy. However, while soft starters are only used to make the startup or stopping process “soft,” VFDs allow control over the motor’s speed throughout its operation, reversing the motor’s rotation, and offer many other flexible control features. This not only helps meet technology demands in various scenarios but also saves energy in many different applications.

VFDs are larger in size and require higher initial investment costs compared to soft starters, especially in high-power applications. Therefore, if your application only requires limiting current during startup, has a stable power grid, doesn’t require changing motor speed, and has no other specific requirements, a soft starter can be an effective solution. However, although the initial investment cost of VFDs may be higher in some cases, they can save up to 50% of energy consumption, which can result in operational cost savings throughout the equipment’s lifespan.

In summary, the choice between a soft starter and a variable frequency drive often depends on the specific application, system requirements, and costs (both initial investment and the system’s lifecycle costs). Making the wrong choice can lead to inefficiencies and potential damage to the motor and other equipment in the plant. Therefore, users should carefully consider all factors before making a decision or consult DAT’s experts for the most efficient solutions.