What is PLC Programming?

Users can program PLCs to execute a series of events. These events are triggered by stimulating agents (inputs) acting on the PLC or through time-based or counted events. PLCs are used to replace relay circuits in practice. PLCs operate by scanning the states of inputs and outputs. When there is a change in the input, the output will change accordingly. The programming language of PLCs can be Ladder or State Logic. Nowadays, many manufacturers produce PLCs, such as INVT, Allen-Bradley, Omron, Honeywell…

How Does PLC Work?

When the device is activated (ON or OFF state due to external physical control devices), a programmed control unit will continuously loop through a program (scan cycle) set by the user and wait for signals to appear at the inputs and output signals at the outputs.

To overcome the shortcomings of wired control units (Relay control units), PLCs were created to satisfy the following requirements:

- Easy programming, easy-to-learn programming languages.

- Compact and easy to store, repair.

- Large memory capacity to accommodate complex programs.

- Completely reliable in an industrial environment.

- Able to communicate with other smart devices such as computers, networking, and various expansion modules.

- Competitive individual prices.

PLC Structure

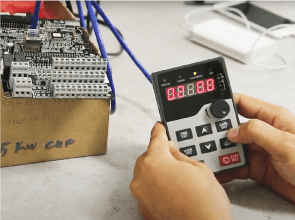

All PLCs have the following main components: An internal program memory (RAM, which can be expanded with additional external EPROM memory). A central processing unit with a communication port for connecting to the PLC. Input/output modules.

In addition, a complete PLC unit also comes with a manual or computer-based programming unit. Most simple programming units have enough RAM to store the program in its entirety or as an add-on. If the programming unit is a portable unit, the RAM is typically CMOS with a backup battery, and it transfers the program to the PLC memory only when the program has been checked and is ready to use. For larger PLCs, programming is typically done on a computer to facilitate program writing, reading, and testing. Programming units are connected to PLCs via RS232, RS422, RS485 ports, etc.

Applications of PLC

PLC programming is widely used in various industries and types of machinery, including printers, packaging machines, fiber spinning machines, sewing machines, food processing machines, high-speed cutting machines, and production line monitoring and control systems.