Solutions to save energy and improve technology for industrial boiler systems

The solution using INVT inverter GD20/GD200A to control the motor speed in the boiler helps to stabilize the steam flow and pressure, save electricity, and increase lifetime of the engine.

A boiler is a device that uses fuels such as (coal, firewood, rice husk, shredded paper, etc.) to boil water and form heat-carrying steam for industrial production such as: textile dyeing, sugar, beverage, food processing, etc.

The main power consuming devices of the system include exhaust fans, blowers and feed conveyors. In the old-style operating method, the motors are started by star delta starter and the pressure relay is used to control directly opening/closing of the exhaust and blower fans.

CUSTOMERS’ DIFFICULTIES

- Unstable steam flow and pressure.

- Starting is not smooth, cause mechanical shock, regularly check and maintain mechanics and engines.

- The engine is always running at full capacity, wasting energy.

- The system needs many electrical devices such as timers, relays, etc.

- The system generates a lot of emissions and the concentration of toxic substances increases suddenly, affecting health and the environment.

SOLUTION ANALYSIS

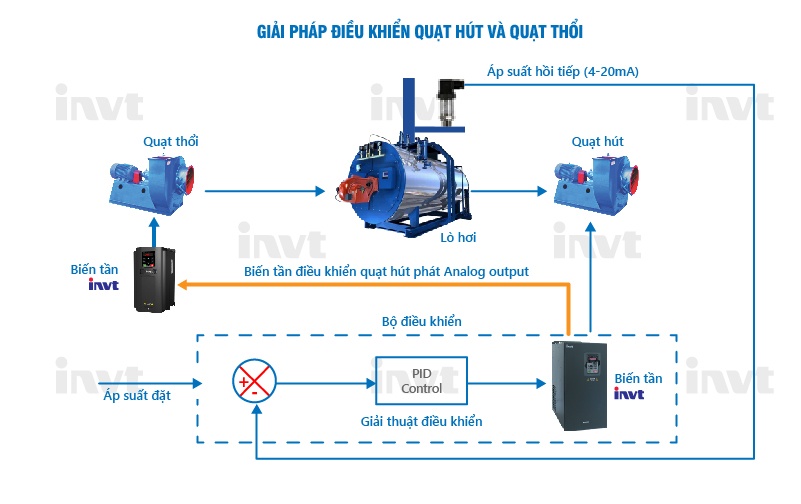

Using INVT inverter for exhaust fan motor, blower fan and feed conveyor. At running status, the inverter controls the exhaust fan motor to run first and then after a period of time the frequency will activate the inverter to control the blower fan to run. The inverter integrates the PID algorithm to receive signals from the pressure sensor on the pipeline, control the exhaust fan motor, blower fan and conveyor to operate in accordance with technology requirements.

SOLUTION ADVANTAGES

- Stabilize steam flow and pressure

- Smooth start of the motors, avoiding mains voltage drop

- Save up to 20% power consumption

- Saving fuel burning

- Easy operation system, ensuring engine safety

- Package solution, available warehouse, 24/7 service

Take a look at DAT's specialized solution design process.

Contact an expert

If you need advice and learn about DAT’s solutions, please contact 1800 6567 to meet with experts today.

Products for solutions

Solution relate:

10.000+

15+

3000+

24h

Let's go with DAT

24/7 SUPPORT

Hotline 1800 6567